Current collector frame and overhead crane using the current collector frame

A technology for bridge cranes and collector racks, which is applied in the direction of load hanging components, transportation and packaging, etc. It can solve problems such as affecting coordination, damage to shutdown, and fixing slip lines, etc., to achieve reliable and accurate installation positions, and facilitate assembly and adjustment , the effect of flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

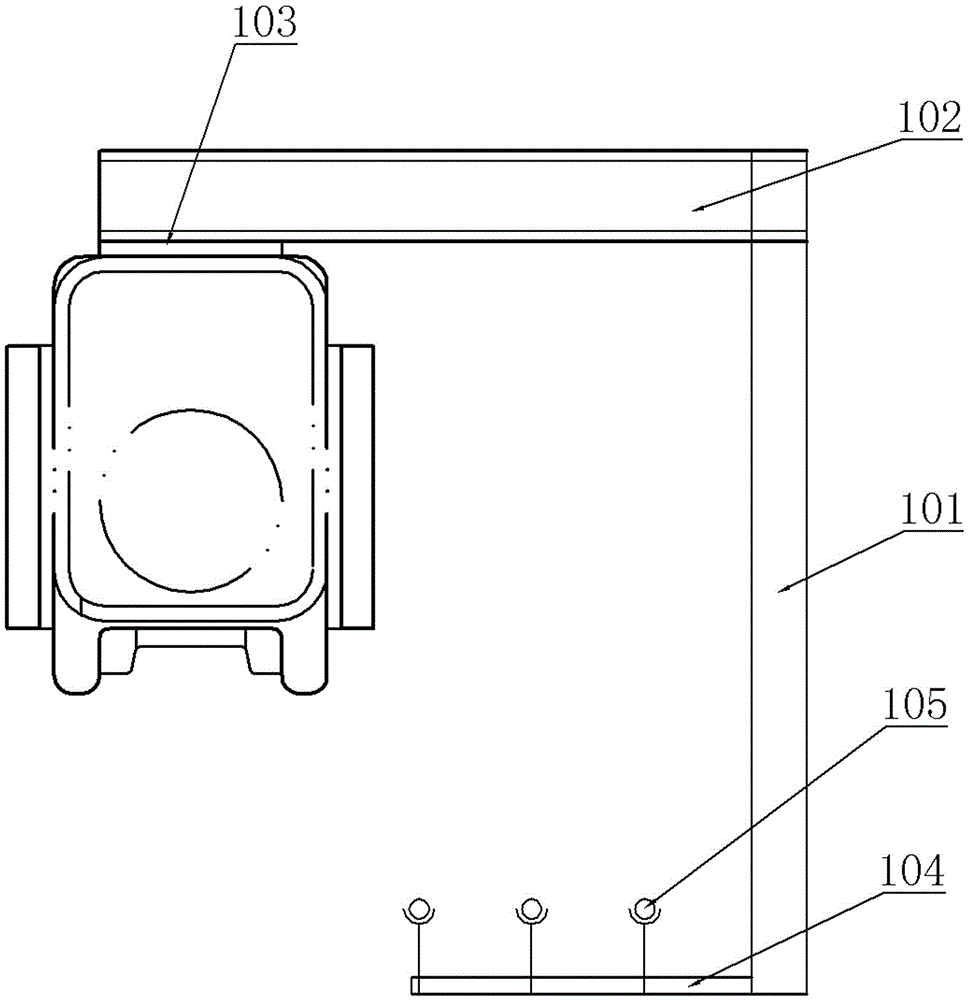

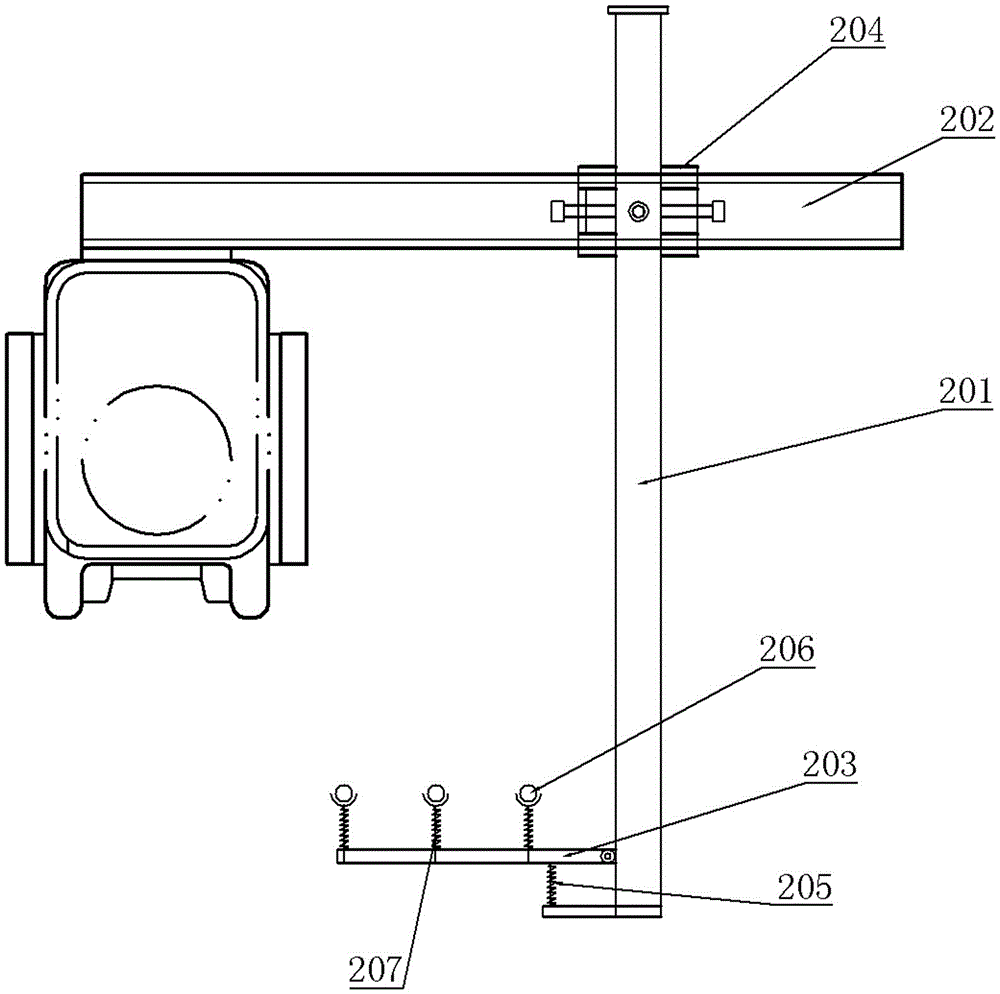

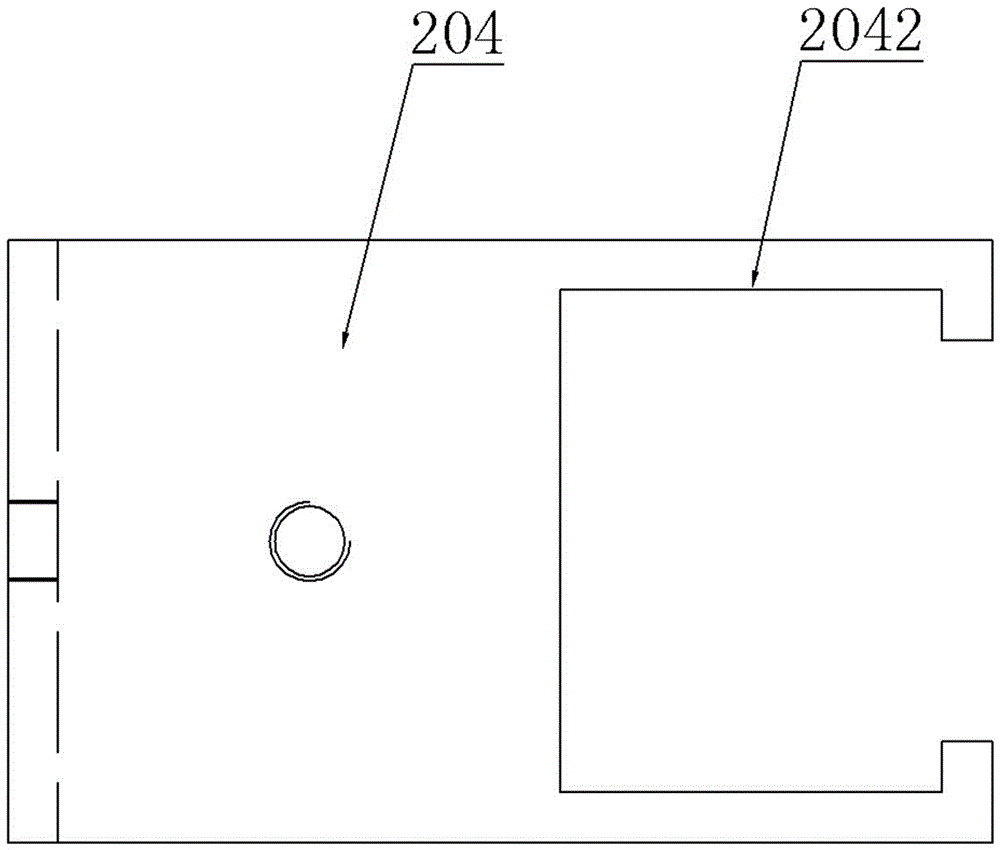

[0023] The embodiment of overhead crane in the present invention: as Figure 2 to Figure 5 As shown, the bridge crane includes an end beam, a collector frame assembled on the end beam, and a collector 206 installed on the collector frame. The collector frame is an adjustable collector frame device for a bridge crane, which includes a vertical guide Frame 201, left and right guide frame 202 and collector bracket 203, left and right guide frame 202 is assembled on the top of vertical guide frame 201 by connector, and connector is the adjustment slip hoop 204 that is assembled on the vertical guide frame 201 outer periphery, adjusts slip hoop 204 is provided with a vertical perforation 2041 for the vertical guide frame 201 to guide and wear up and down, and three locking holes for screwing locking bolts are provided on the hole wall of the vertical perforation 2041, so that the connecting piece can pass through the vertical The perforation 2041 can be lifted and fixed on the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com