System using solenoid groups to achieve electromagnetic guiding distance measurement while drilling

A guiding system and solenoid technology, applied in construction and other fields, can solve the problems of core technology confidentiality, limited measurement accuracy, monopoly, etc., and achieve the effect of easy distance measurement range, high measurement accuracy, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described below in conjunction with the drawings and embodiments.

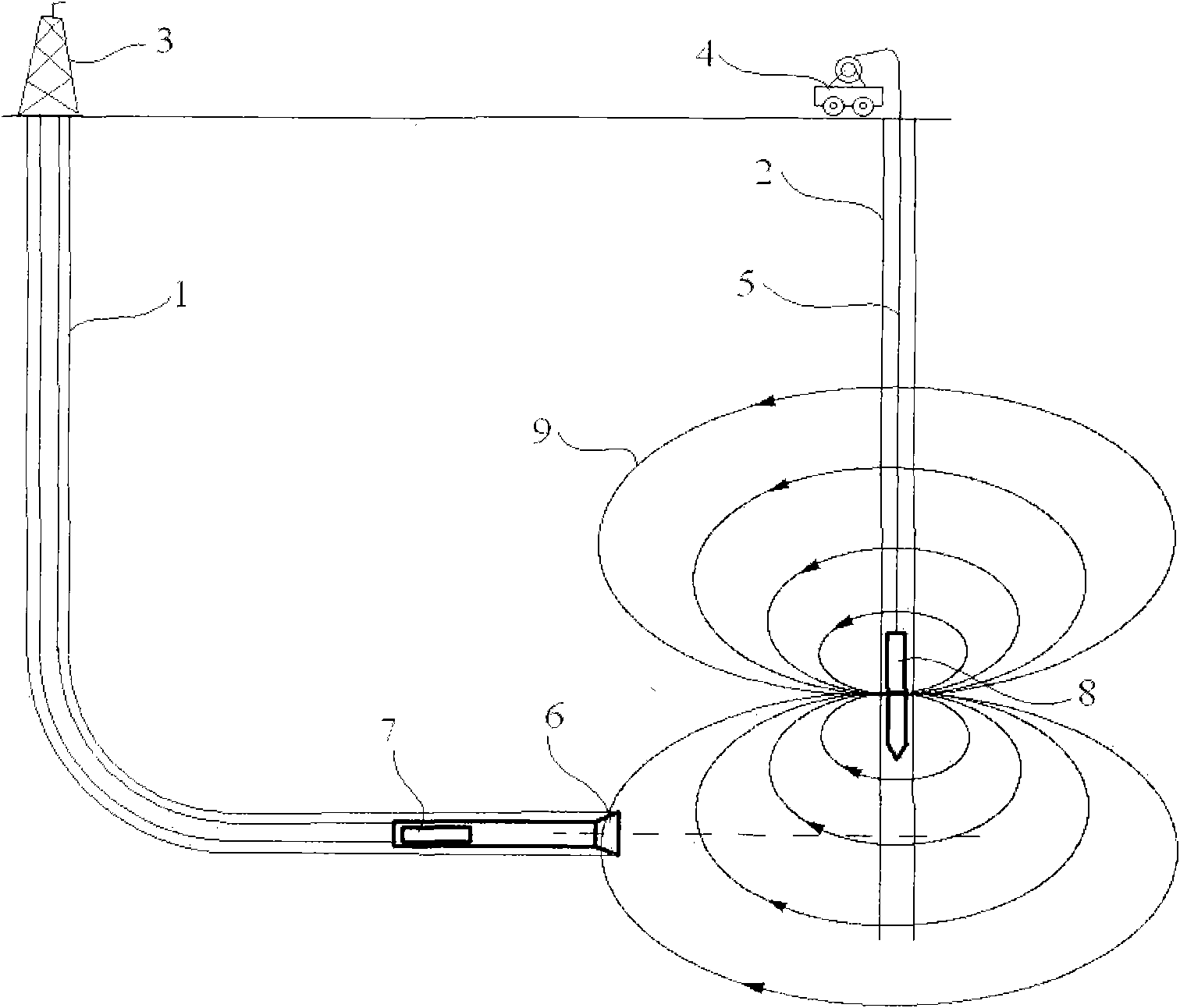

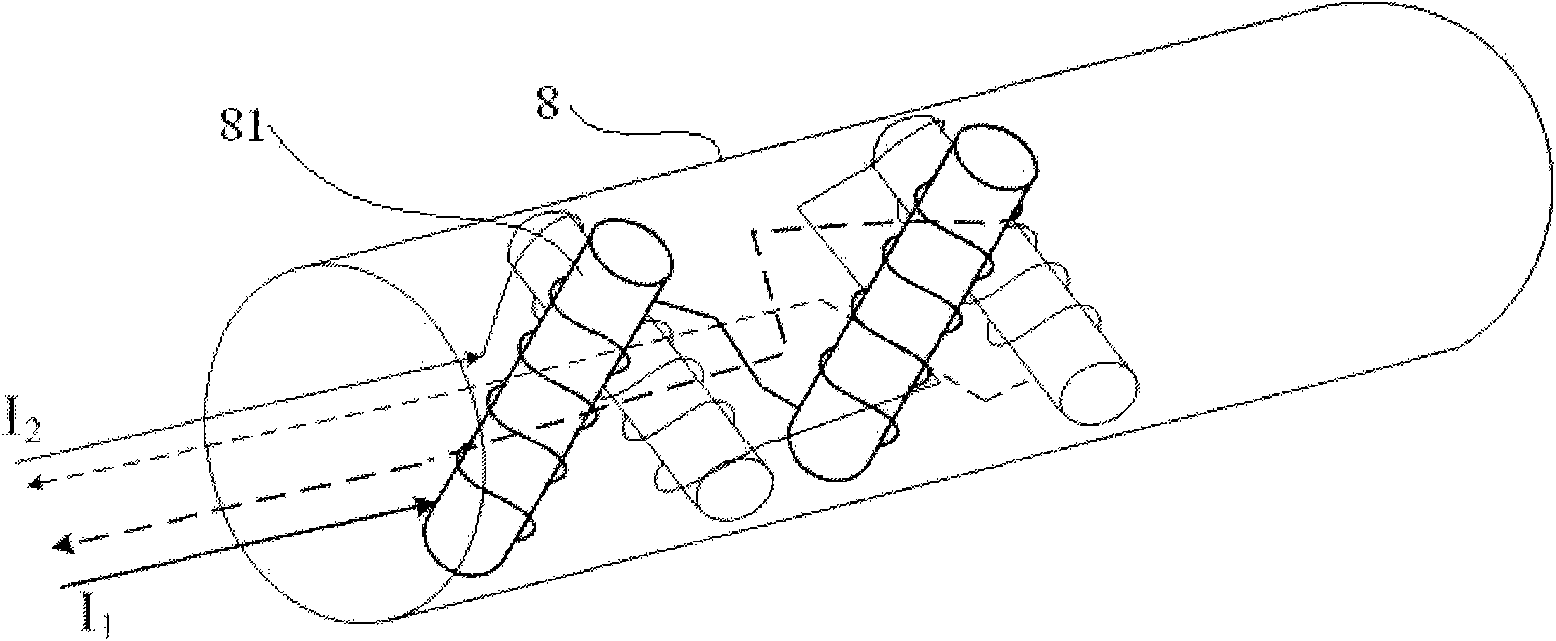

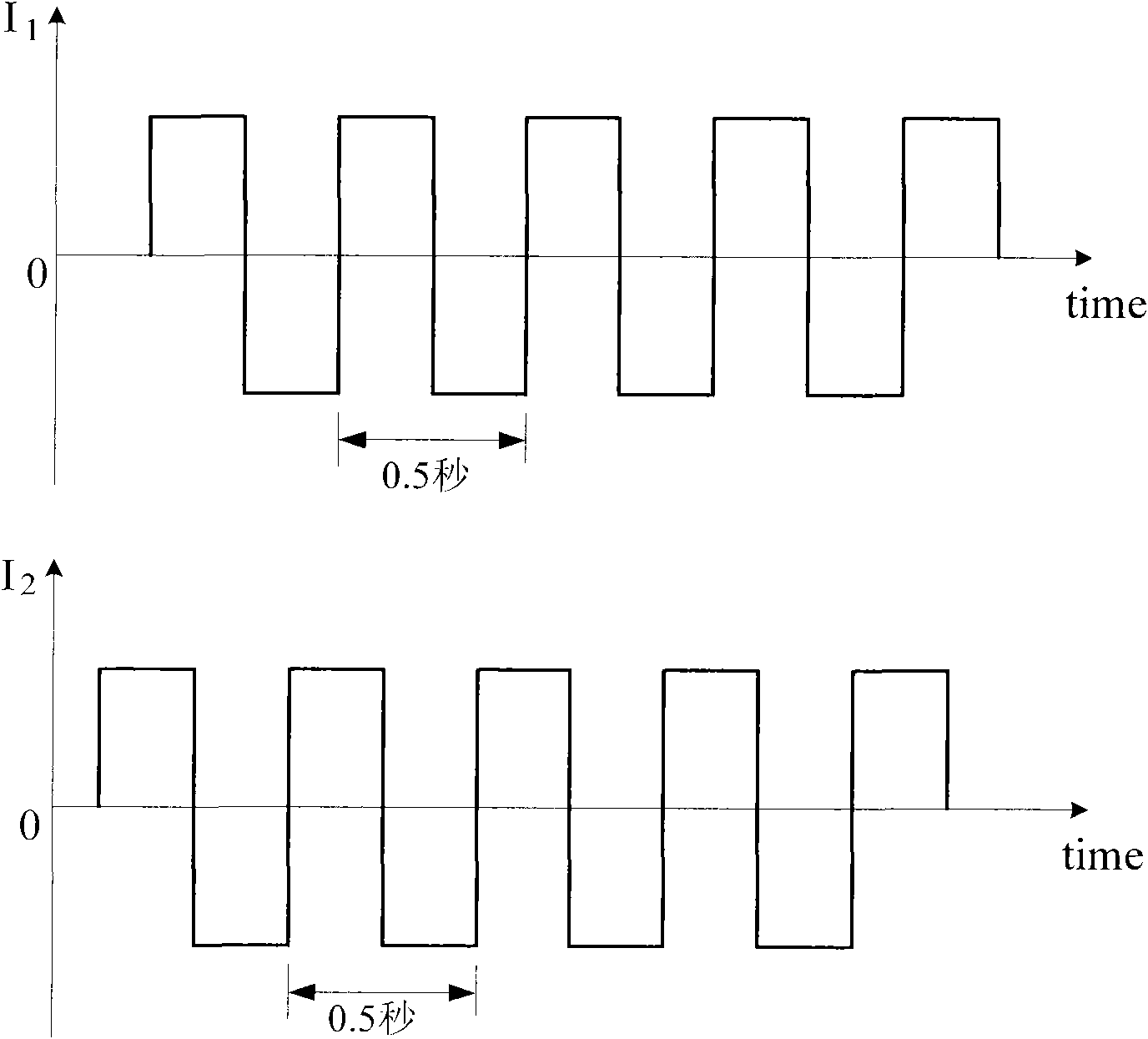

[0027] Such as figure 1 As shown, the hardware of the electromagnetic ranging and guidance system of the solenoid group while drilling is mainly composed of the solenoid group sub-section, the modified MWD, and ground equipment. The modified MWD is placed in the drilling well, following the traditional MWD installation position behind the drill bit, and detects the rotating magnetic field generated by the solenoid stack sub-joint in the adjacent well (drilled). Then, the detected magnetic vector signal is transmitted from the MWD to the ground computing system, and the relative position of the MWD to the sub-joint of the solenoid group is obtained. Furthermore, combined with the positional relationship between MWD and the drill bit, the relative position of the drill bit to the sub-section of the solenoid group can be calculated. Finally, the surface adjacent well spacing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com