Half-feeding harvester feeding depth control mechanism

A control mechanism and technology for harvesters, which are applied in the directions of harvesters, agricultural machinery and implements, cutters, etc., can solve the problems that relays are easy to ignite, affect the harvesting efficiency and wear of half-feed harvesters, and achieve convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

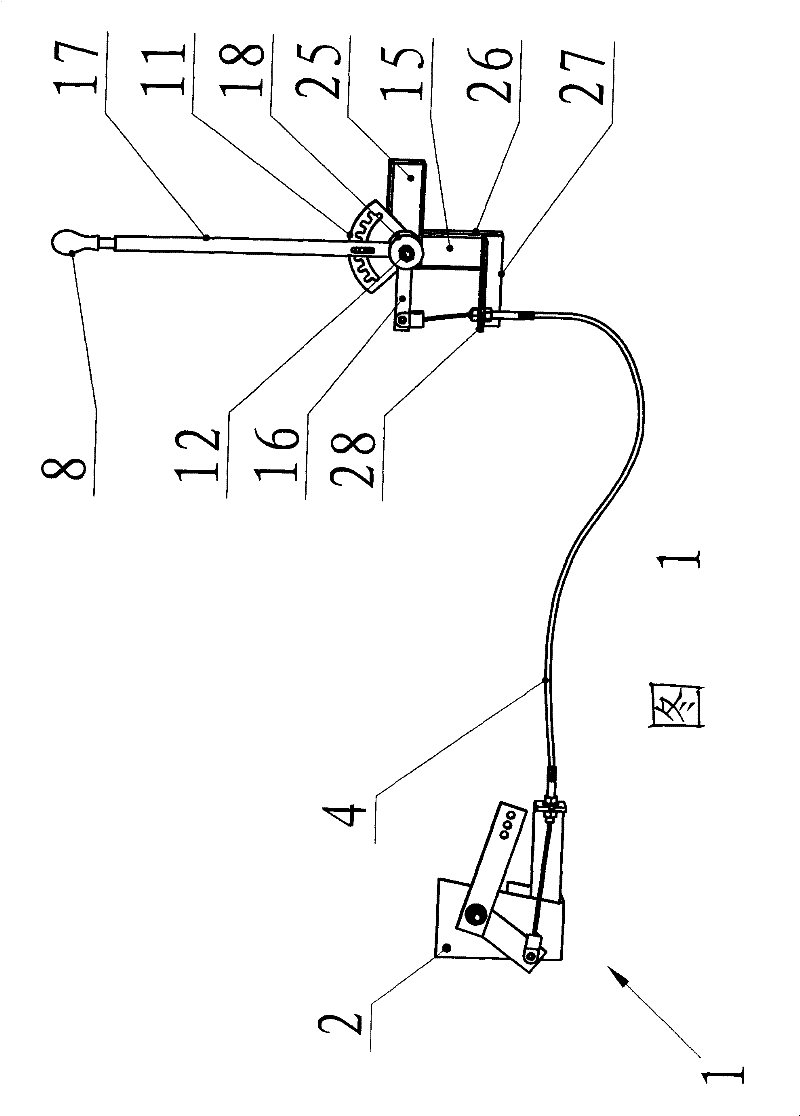

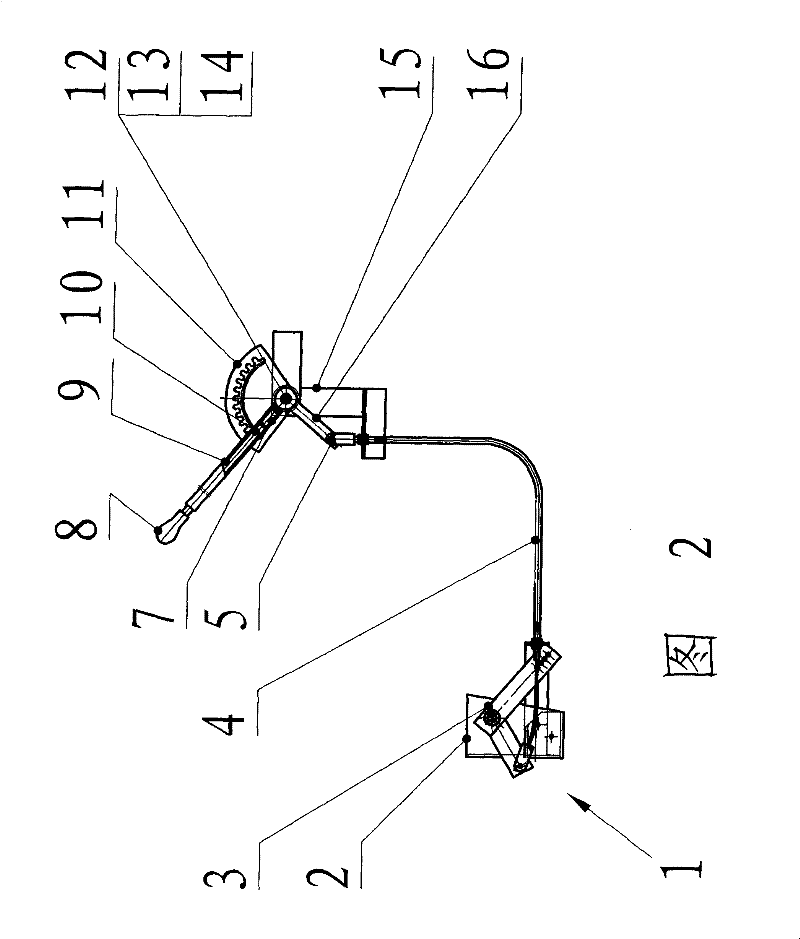

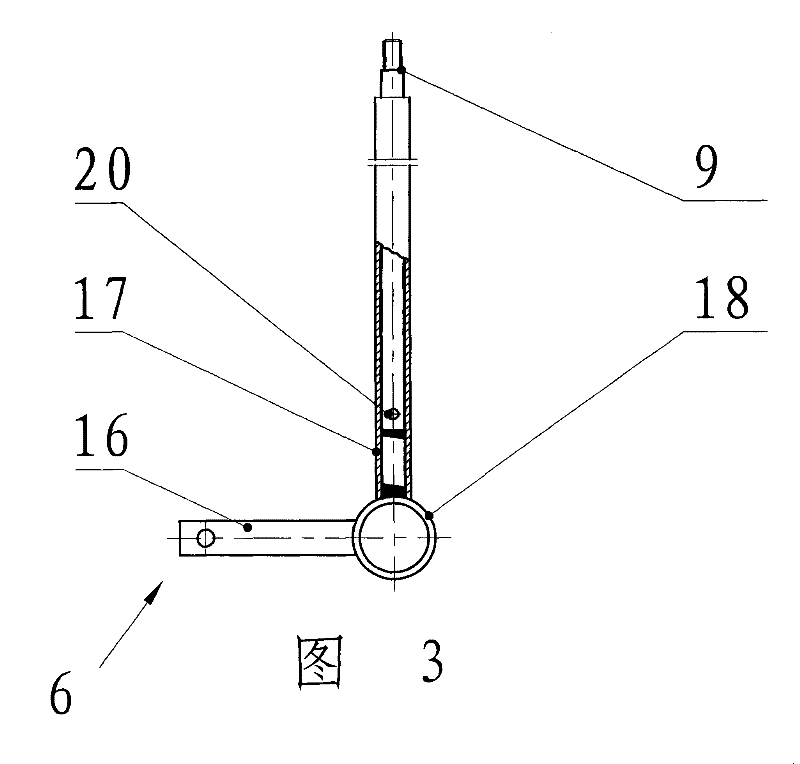

[0044] see figure 1 with figure 2 , the feeding depth control mechanism 1 of the semi-feeding harvester of the present invention is mainly composed of the lower bracket 2, the depth guide rail control arm 3, the flexible shaft 4, the pin shaft 5, the joystick welding 6, the compression spring 7, the handle 8, and the manipulation pressure rod 9. The limit fixing plate pin shaft 10, the limit fixing plate 11, the shaft 12, the damping bushing 13 and the upper bracket 15 are composed of a deep and shallow guide rail control arm 3 installed on the lower bracket 2 of the semi-feeding harvester header, In the connecting fork pin hole 37 of the flexible shaft connecting plate 34 of the deep and shallow guide rail control arm 3, pin shaft is housed, and the connecting fork at the lower end of flexible shaft 4 is installed on the pin shaft in the described connecting fork pin hole 37. The connecting plate pin hole 36 of the deep and shallow connecting plate 33 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com