Unmanned aerial vehicle electrified rust removal device and operation method thereof

A technology of unmanned aerial vehicle and derusting liquid, which is applied in the direction of launching devices, unmanned aircraft, motor vehicles, etc., can solve the problems of cumbersome operation steps, defect processing efficiency and impact, and achieve the effect of expanding the scope of derusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments in the present invention, those of ordinary skill in the art will belong to the scope of the present invention without all other embodiments obtained in the preparation of creative labor.

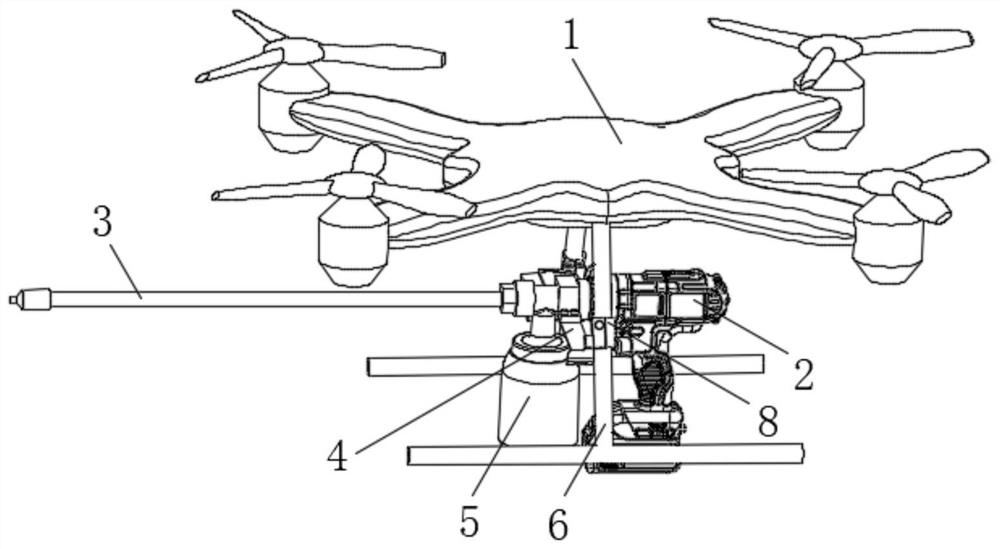

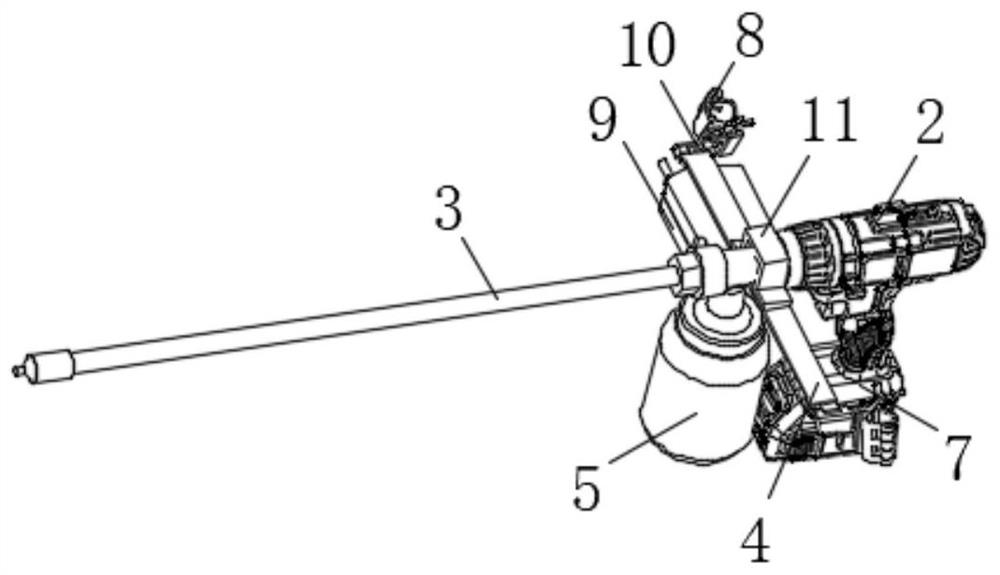

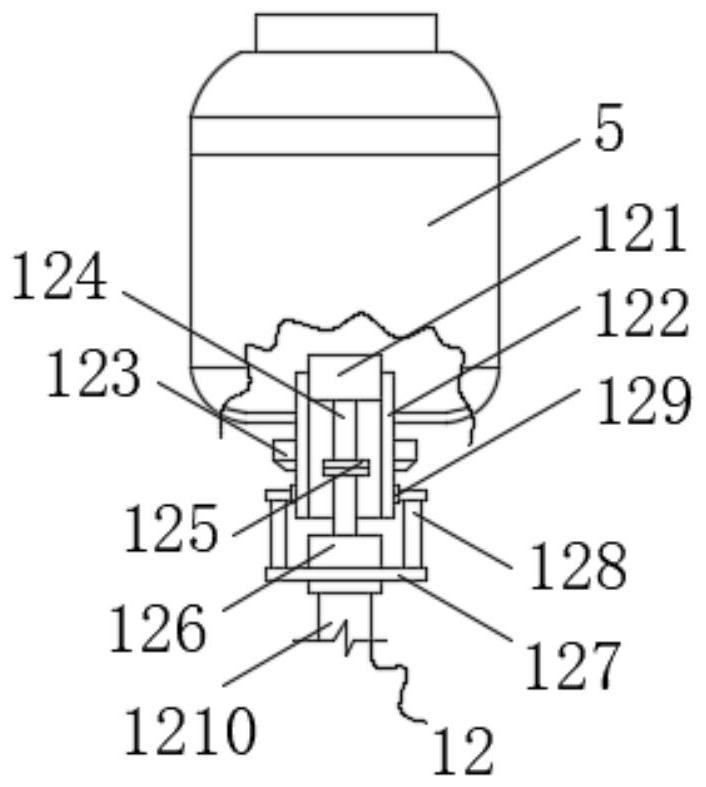

[0036] See Figure 1-7 The present invention provides a technical solution: a charging UAV descaling apparatus 1 comprises a UAV, the electric gun 2, the lance means 3 and electric watering 5, the lower front and rear sides of the UAV 1 are surface bracket 6 is fixedly connected UAV, UAV arranged between two brackets 6 support plate 4, both ends of the support plate 4 are fixedly connected with articulating member 10, the movable connecting member 10 fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com