Rivet punching jig of thin core board

A technology of rivets and core boards, which is applied in the manufacture of multilayer circuits, electrical components, printed circuits, etc., can solve the problems of poor electrical properties, lack of fixation, misalignment between layers, etc., and achieve light overall weight, Good positioning effect and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

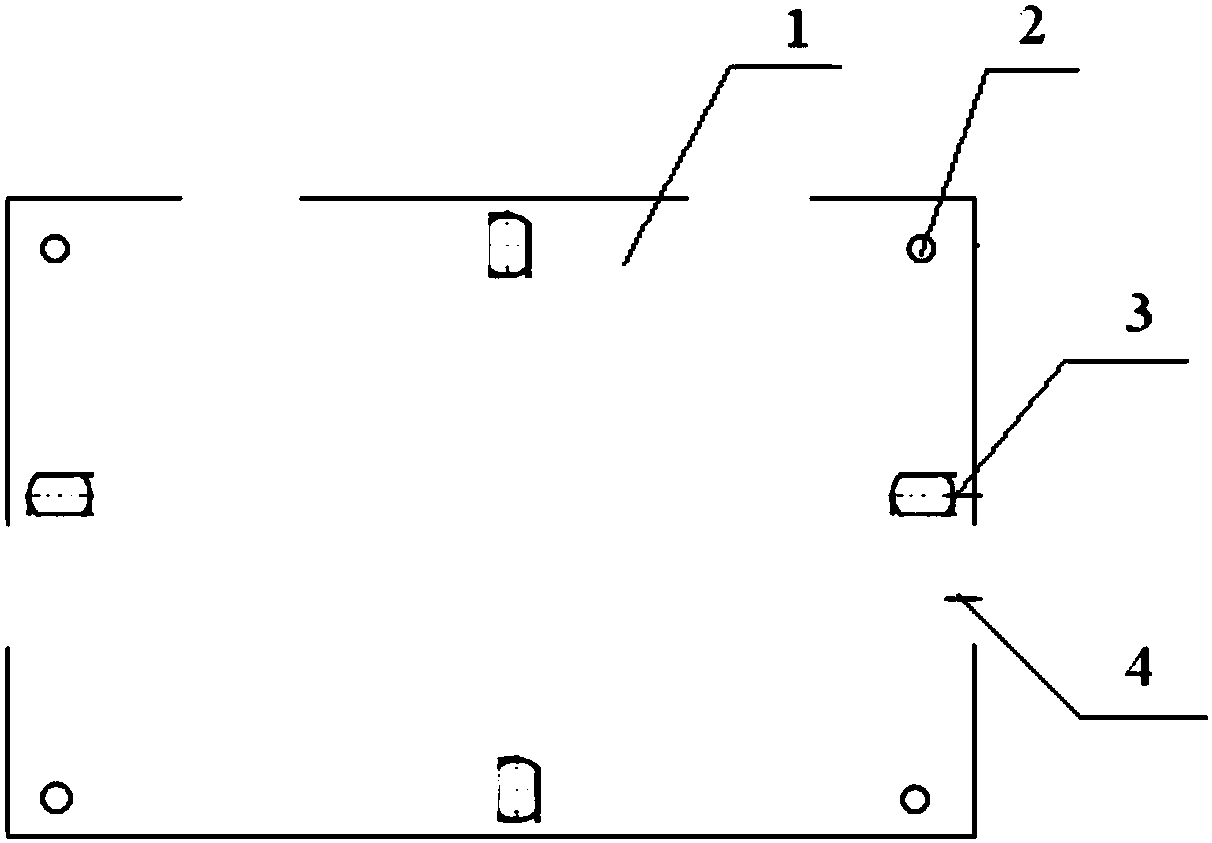

[0017] Such as figure 1 As shown, a thin plate core plate rivet fixture includes a copper-free substrate 1, and also includes a rivet hole 2, a slot hole 3 and a window 4; the four corners of the copper-free substrate 1 are provided with rivet holes 2, A slot 3 is provided on each side of the copper-free substrate 1; two windows 4 are respectively opened on the upper and lower sides of the copper-free substrate 1, and one window 4 is opened on each side of the two sides.

[0018] The diameter of the rivet hole 2 is 3.175mm. The size of the slot 3 is 280*187mil. The window 4 is 5cm*5cm.

[0019] In the present invention, four rivet holes 2 of 3.175mm are drilled on the corners of the copper-free substrate 1, the purpose is to reserve the rivet holes for joining two copper-free substrates 1 together; Punch out 4 more slotted holes 3 (size 280*187mil); then remove 6 windows 4 of 5cm*5cm from the position where the rivet needs to be riveted.

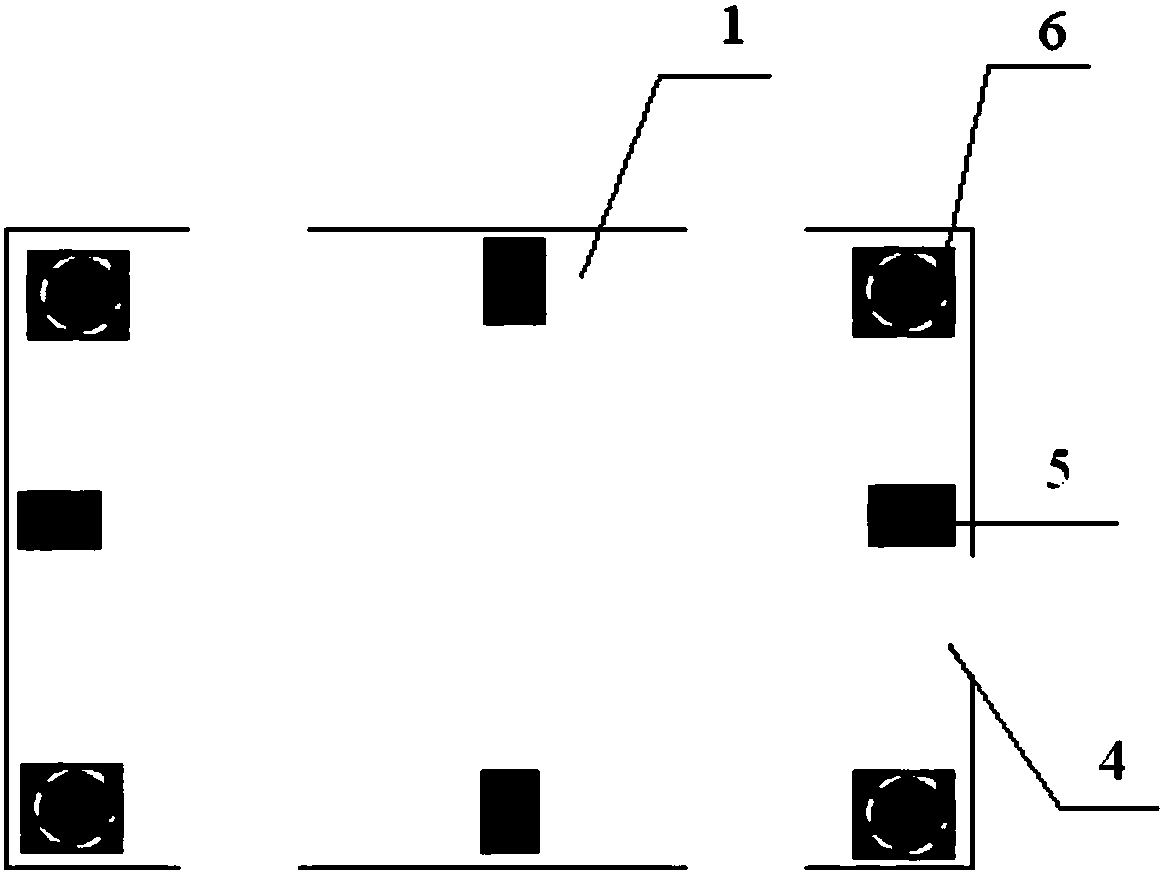

[0020] Such as figure 2 As show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com