Underwater servo propeller

A technology of propulsion and controller, applied in the direction of propulsion components, ship propulsion, instruments, etc., can solve the problems of high price, no availability, changes in the corresponding relationship, etc., and achieve the effect of small size and high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings: this embodiment is implemented on the premise of the technical solution of the present invention. The detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following examples.

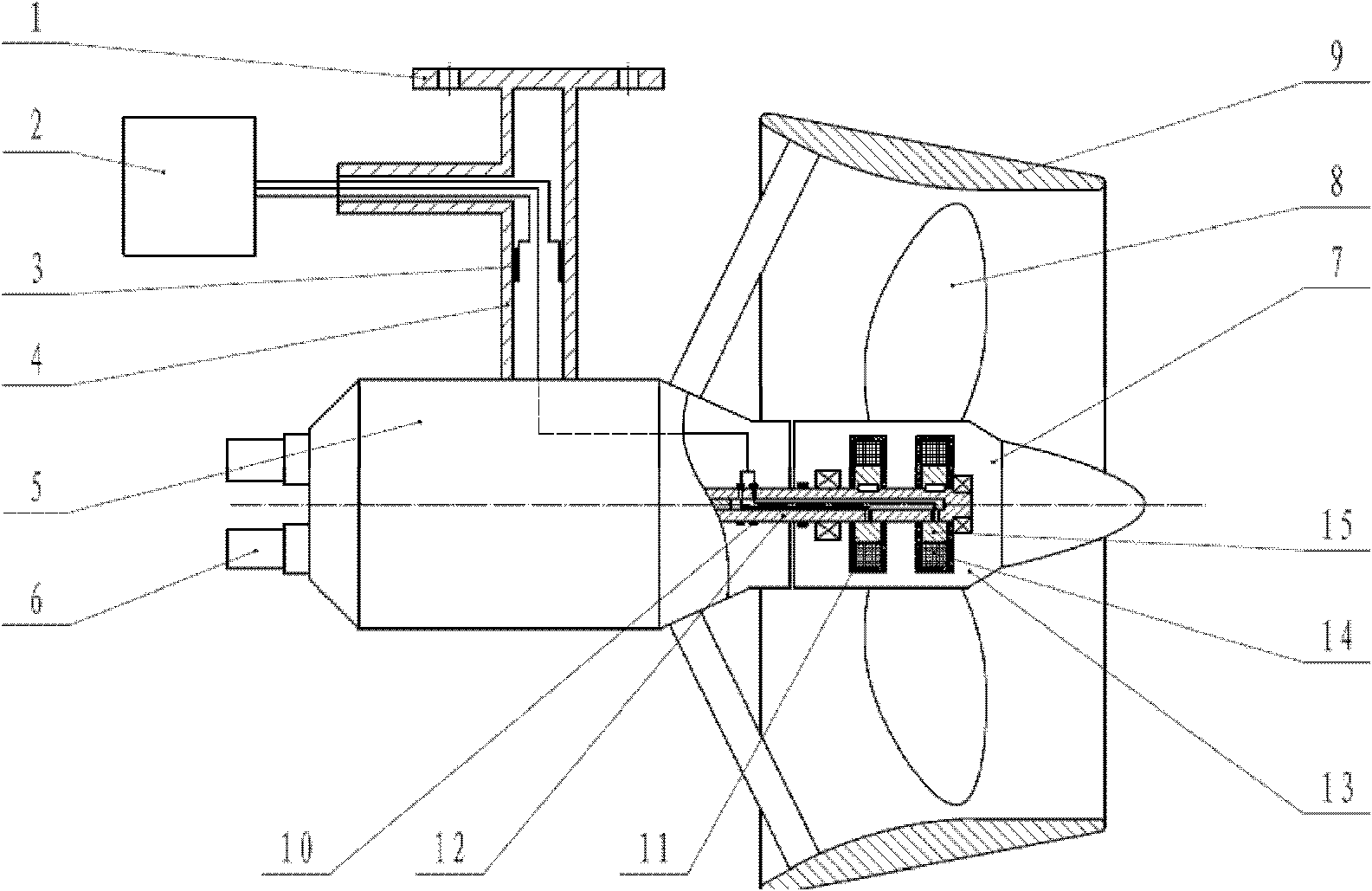

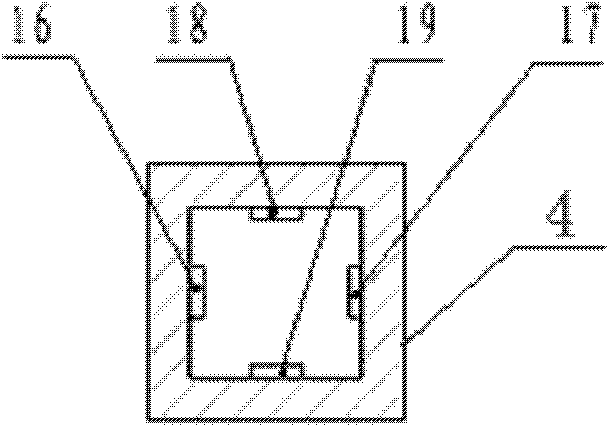

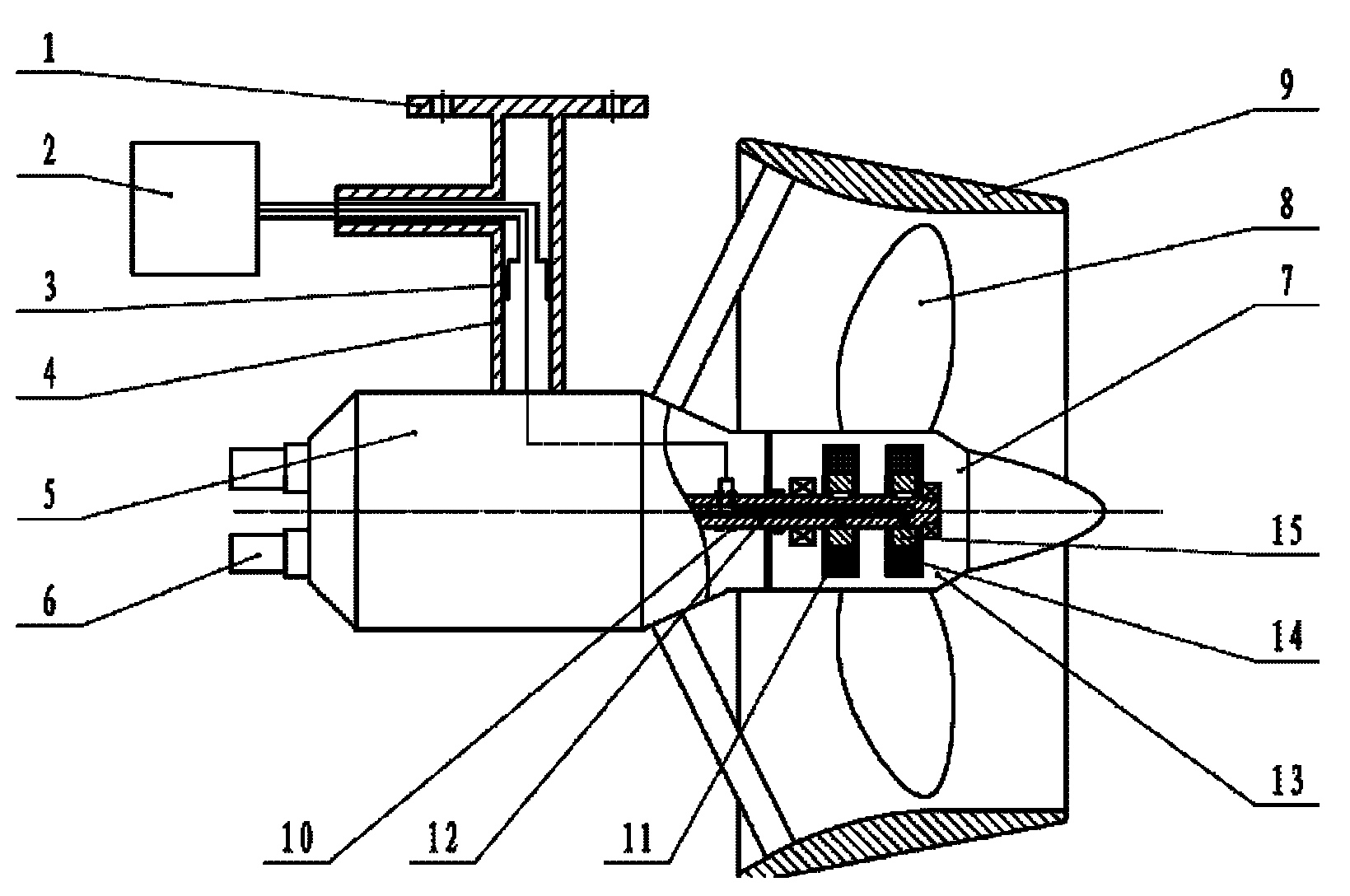

[0016] Such as figure 1 As shown, this embodiment includes: a connecting flange 1, a controller 2, a load cell 3, a suspension frame 4, a hydraulic motor 5, a hydraulic pipeline interface 6, a magneto-rheological fluid torque coupler 7, a propeller 8 and a conduit 9, wherein: the connecting flange 1 is connected to the suspension frame 4, the controller 2 is connected to the hydraulic motor 5 to transmit control signals, the hydraulic motor 5 is provided with a hydraulic pipeline interface 6, and the suspension frame 4 is provided with a force sensor 3, The load cell 3 is connected to the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com