Gas path device for metal organic chemical vapor deposition equipment

A metal-organic and chemical deposition technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve problems such as difficult precise control of gas flow, influence on the quality of generated crystals, and large control errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. In the specification, the same or similar reference numerals designate the same or similar components. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

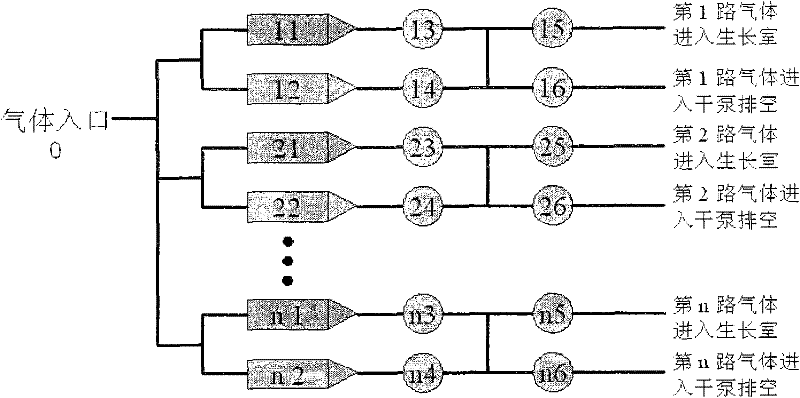

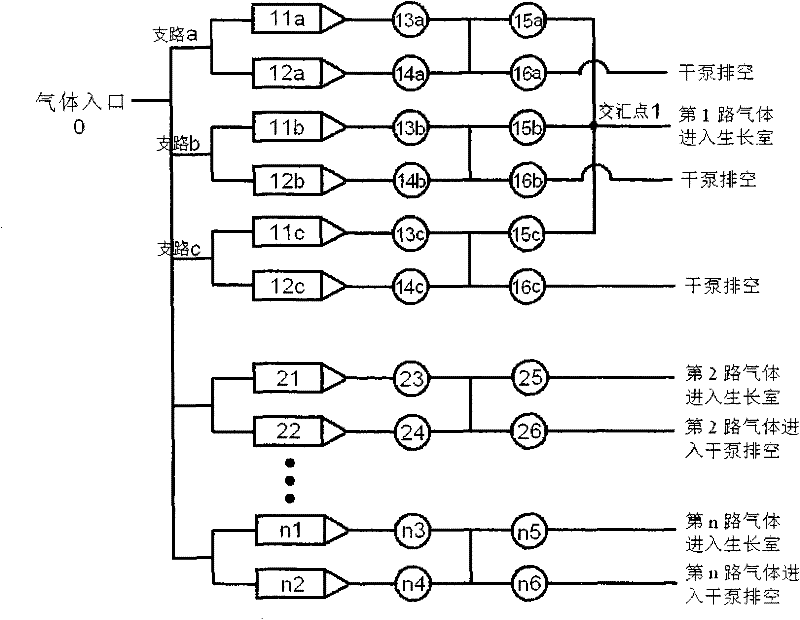

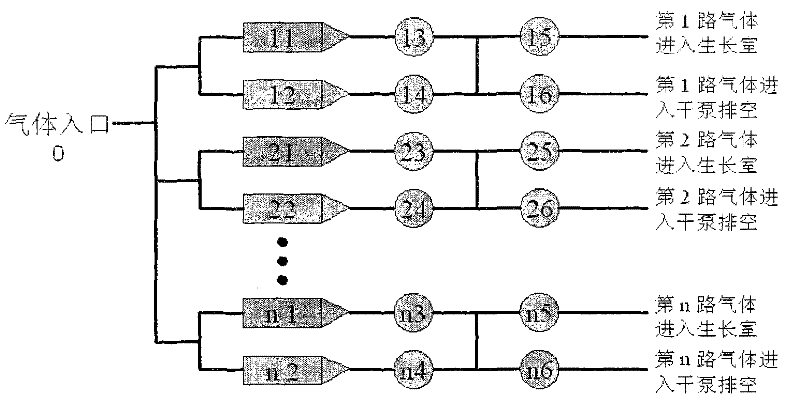

[0021] The gas path device for metal-organic chemical deposition equipment according to the present invention includes: a gas inlet 0; multiple groups of gas paths drawn in parallel from the inlet 0, each group of gas paths includes a first sub-gas path arranged in parallel and the second sub-gas path, each of the first sub-gas path and the second sub-gas path can be selectively communicated with the growth chamber and the evacuation channel, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com