cooling method

A cooling method and coolant technology, applied in liquid cooling, engine cooling, coolant flow control, etc., can solve problems such as structure and coolant overheating, and achieve the effect of increasing protection and avoiding overheating damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

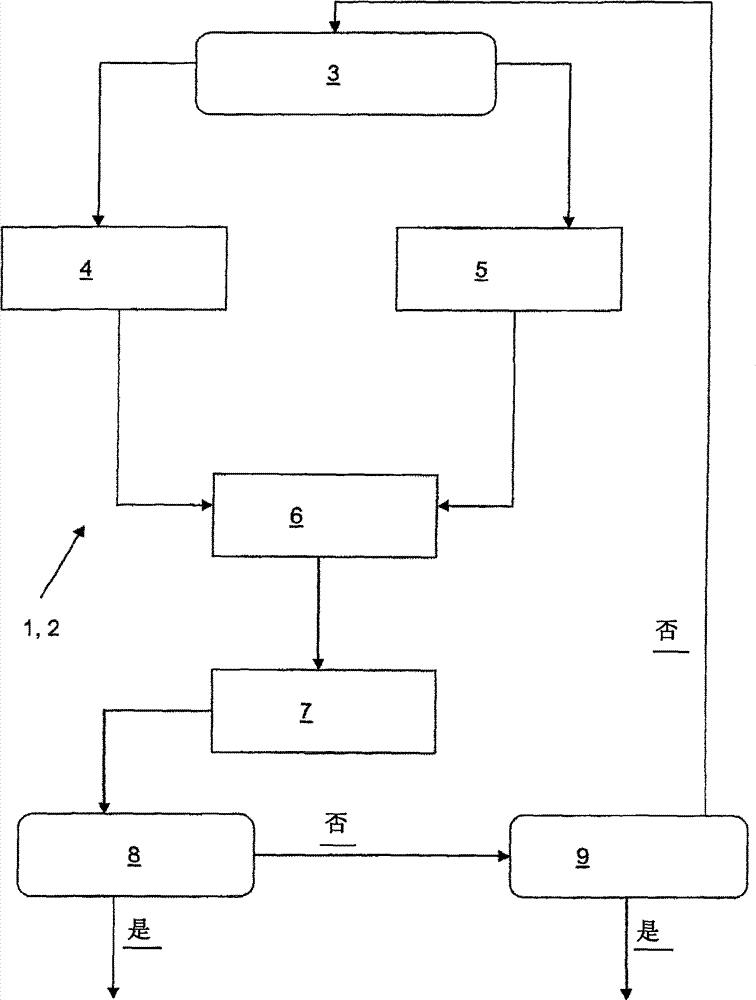

Image

Examples

Embodiment Construction

[0029] Cooling method 2 is preferably implemented in internal combustion engines with a so-called split cooling design. In a split cooling design, the internal combustion engine has a coolant jacket on the cylinder block side and a coolant jacket on the cylinder head side. Preferably, the regulating valve is arranged in the water outlet housing, ie a separate part connected to the cylinder head, and in a preferred embodiment as a thermostat, the regulating valve controls the total flow of coolant, eg for cooling and heating. The regulating valve can also be arranged in the coolant jacket on the cylinder head side. Of course, the control valve can also be arranged at other suitable locations, as long as the coolant flow through the coolant jacket on the cylinder block side can be prevented during the warm-up phase or after a cold start of the internal combustion engine. Another thermostat affecting coolant flow through the cylinder block may be provided in the cylinder block i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com