Water-based silicone rubber porcelainizable flexible facing brick, and production and application thereof

A flexible veneer and vinyl silicone rubber technology, applied in the field of building decoration materials, can solve the problems of casualties, property, organic phase aging resistance, fading and cracking, etc., to meet high-altitude safety and fire protection requirements, and excellent fire safety performance , to avoid the effect of internal explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

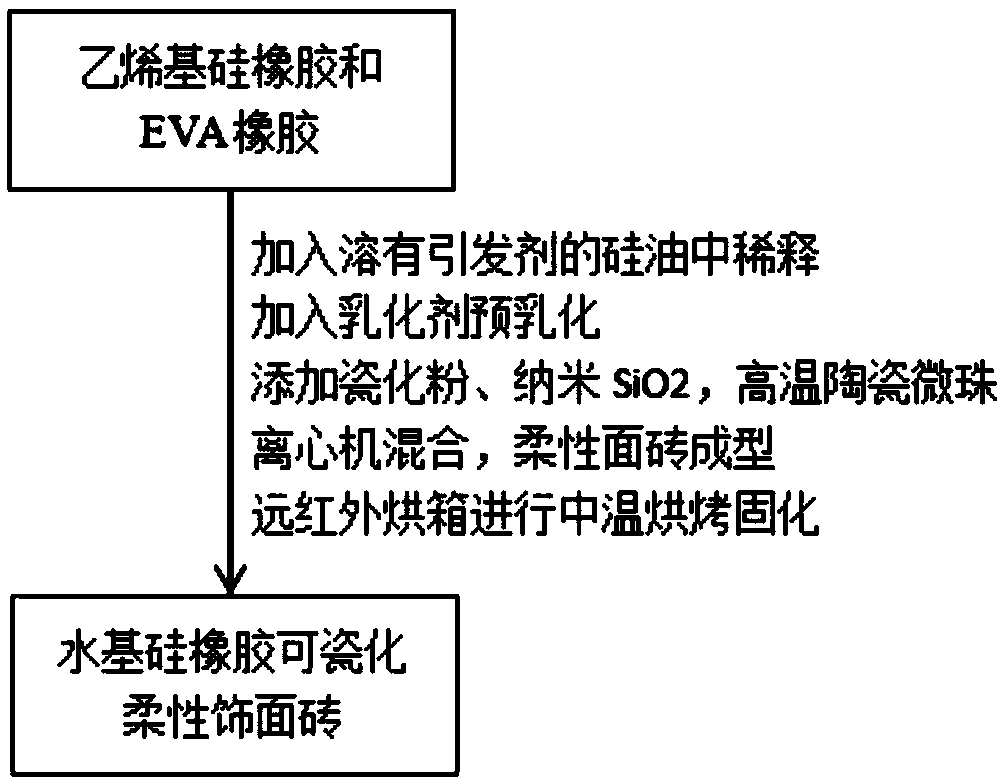

Method used

Image

Examples

Embodiment 1

[0019] Example 1 Preparation of Water-based Silicone Rubber Porcelainable Flexible Facing Brick

[0020] Raw material composition: 70 parts of vinyl silicone rubber, 10 parts of EVA rubber, 10 parts of benzoyl peroxide, 10 parts of lauroyl peroxide, 0.1 part of cetyltrimethylammonium chloride, alkylphenol polyoxyethylene ether 0.1 parts, 5 parts of aluminum hydroxide, 5 parts of montmorillonite, 5 parts of kaolin, nano-SiO 2 2 parts, 1 part of high-temperature ceramic microbeads, 0.01 part of fumaric acid;

[0021] Dilute vinyl silicone rubber and EVA rubber with silicone oil dissolved in benzoyl peroxide and lauroyl peroxide. After high-speed pre-emulsification with cetyltrimethylammonium chloride and alkylphenol polyoxyethylene ether, add Aluminum hydroxide, montmorillonite, kaolin, nano-SiO 2 , high-temperature ceramic microbeads, fumaric acid, fully mixed by a centrifugal mixer, the flexible facing brick is formed, put into a far-infrared oven for 70 ℃ medium-temperatur...

Embodiment 2

[0022] Example 2 Preparation of Water-Based Silicone Rubber Porcelainable Flexible Facing Bricks

[0023] Raw material composition: 90 parts of vinyl silicone rubber, 20 parts of EVA rubber, 10 parts of dicumyl peroxide, 20 parts of cyclohexanone peroxide, 1 part of hexadecyl pyridinium bromide, 1 part of fatty amine polyoxyethylene ether parts, magnesium hydroxide 10 parts, diatomaceous earth 10 parts, kaolin 10 parts, nano-SiO 2 10 parts, 5 parts of high temperature ceramic beads, 1 part of ferrocene, Sb 2 o 3 1 copy;

[0024] Dilute vinyl silicone rubber and EVA rubber with silicone oil dissolved in dicumyl peroxide. Magnesium oxide, diatomaceous earth, kaolin, nano-SiO 2 , high temperature ceramic beads, ferrocene, Sb 2 o 3 , fully mixed by a centrifugal mixer, the flexible facing tiles are molded, and then baked and cured at a medium temperature of 90°C in a far-infrared oven to obtain a water-based silicone rubber porcelain-able flexible facing tile with a yield o...

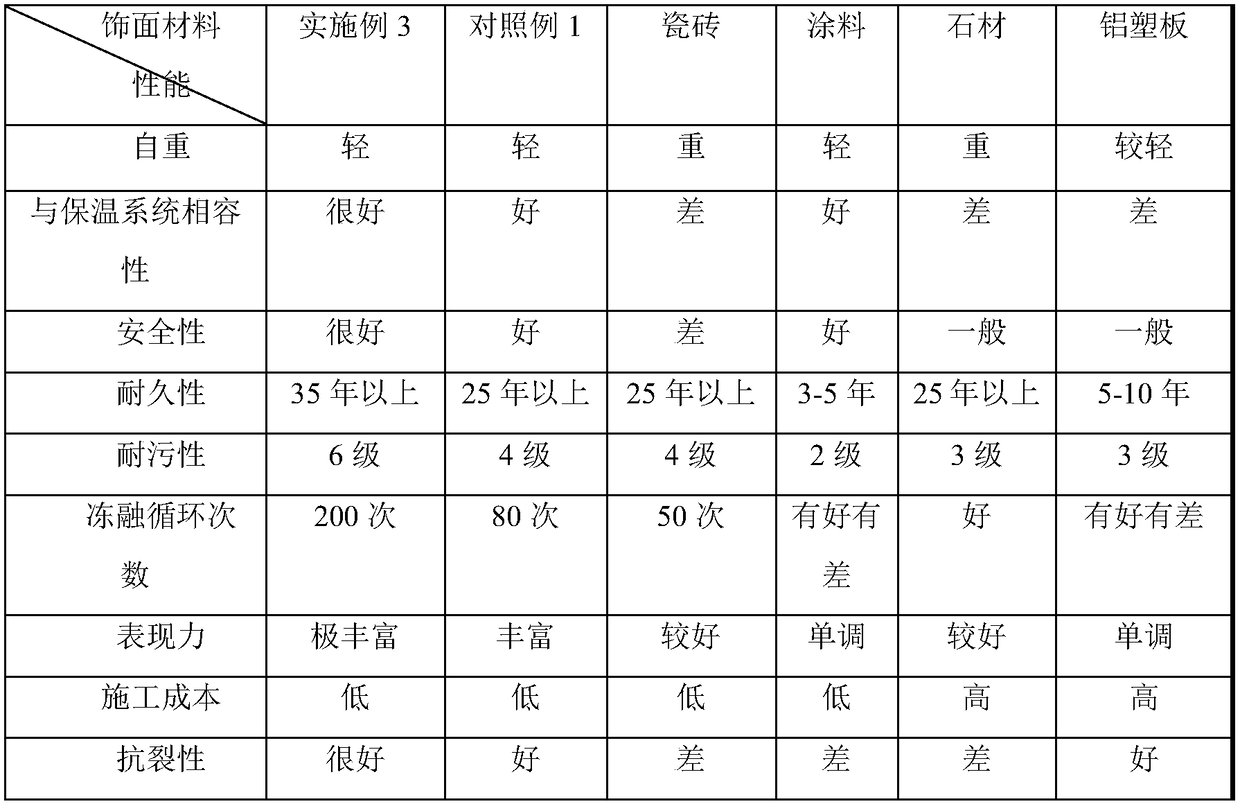

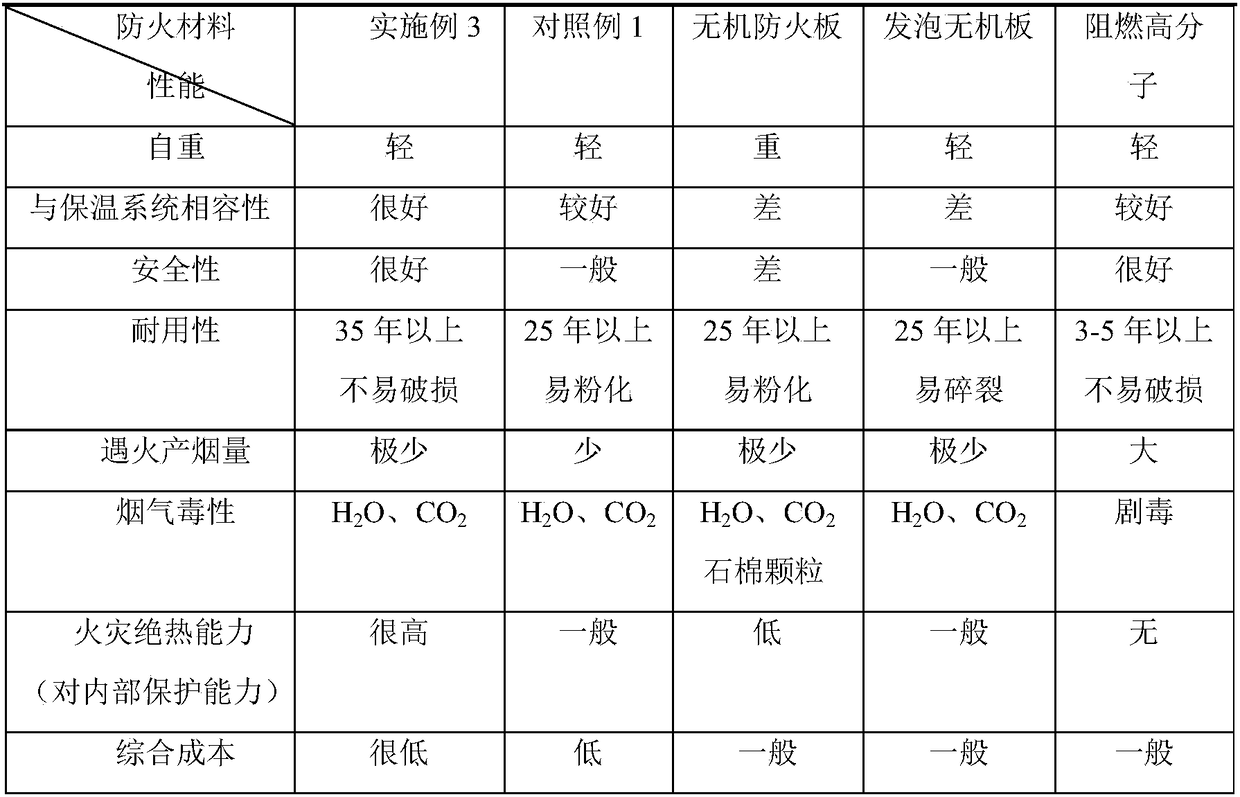

Embodiment 3

[0025] Example 3 Preparation of Water-Based Silicone Rubber Porcelainable Flexible Facing Bricks

[0026] Raw material composition: 75 parts of vinyl silicone rubber, 12 parts of EVA rubber, 22 parts of dicumyl peroxide, 0.1 part of cetyltrimethylammonium chloride, 0.5 part of alkanolamide polyoxyethylene ether, low temperature 6 parts of glass powder, 2 parts of mica powder, 4 parts of diatomaceous earth, 6 parts of kaolin, nano-SiO 2 2 parts, 1 part of high-temperature ceramic microbeads, 0.1 part of molybdenum oxide, 5 parts of cellulose ether thickener, 0.1 part of salicylate ultraviolet absorber;

[0027] Dilute vinyl silicone rubber and EVA rubber with silicone oil dissolved in dicumyl peroxide, pre-emulsify with cetyltrimethylammonium chloride and alkanolamide polyoxyethylene ether at high speed, powder, mica powder, diatomaceous earth, kaolin, nano-SiO 2 , high-temperature ceramic microbeads, molybdenum oxide, cellulose ether thickener, salicylate UV absorber, fully...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com