LED bulb

A technology of LED light bulbs and lamp holders, applied in lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of reduced structural complexity, failure to achieve traditional light bulbs, and influence the popularization and application of LED light bulbs, etc., to achieve convenient design and production, reduce manufacturing costs, ensure reliability and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

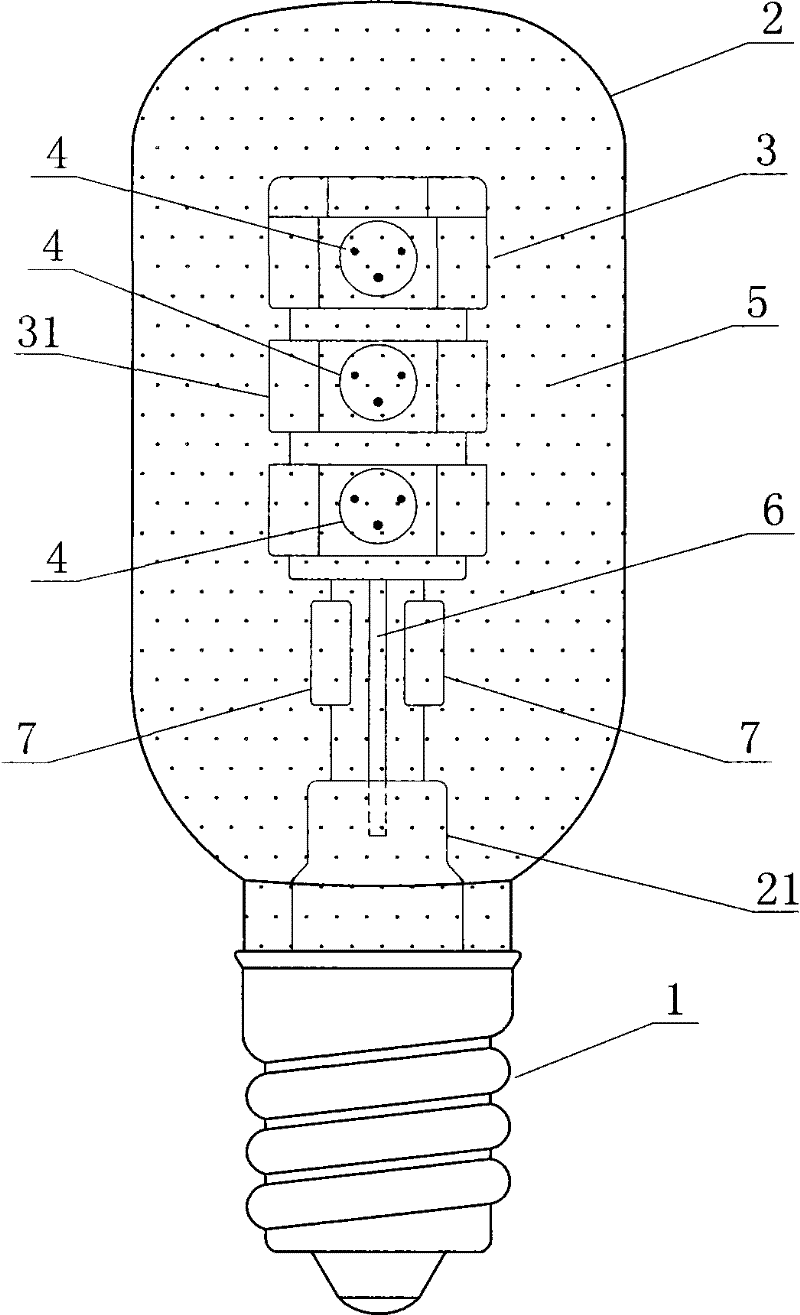

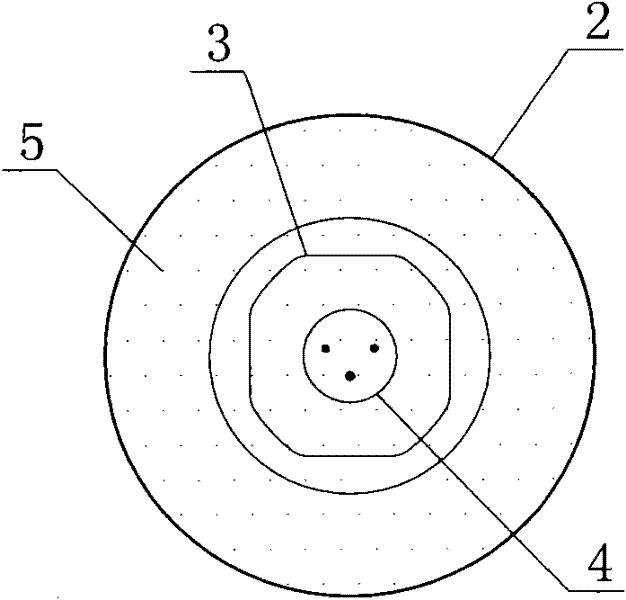

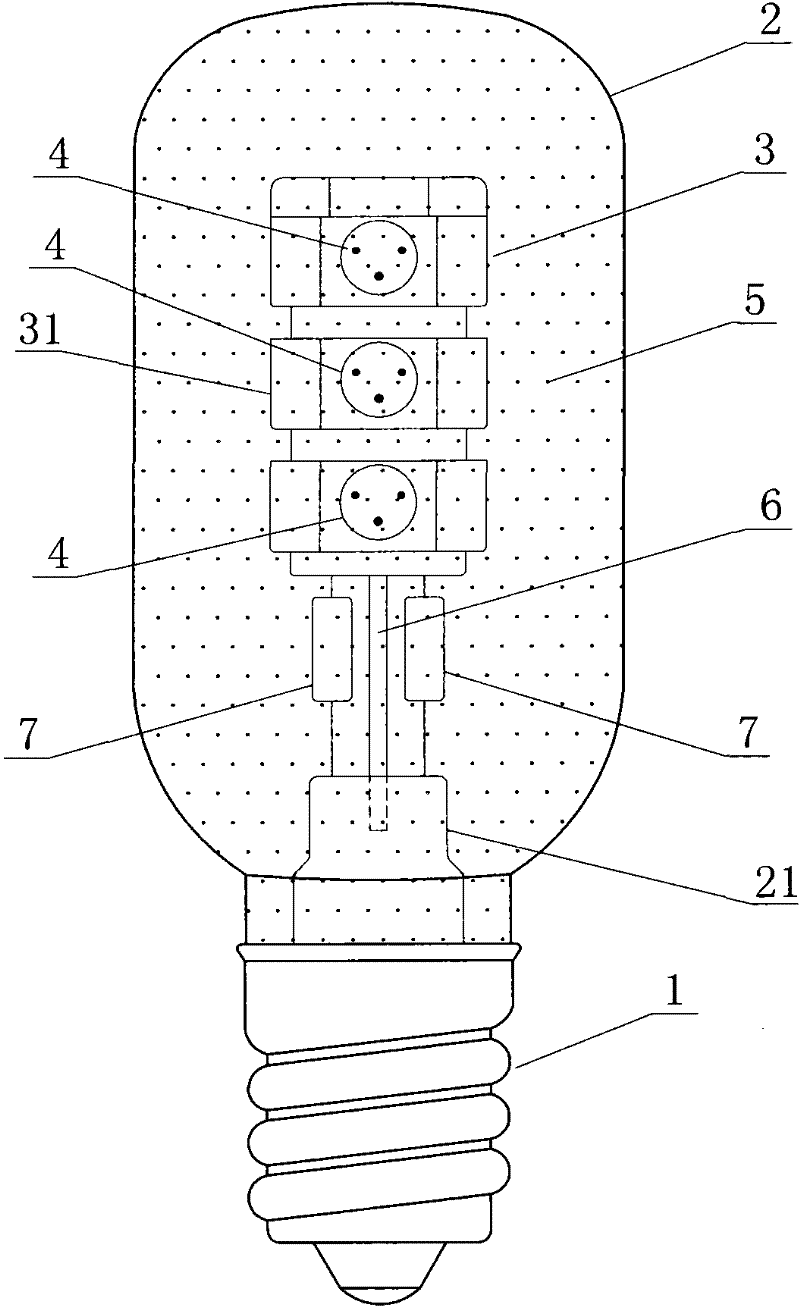

[0014] Such as figure 1 and figure 2 As shown, an LED light bulb according to the present invention includes a lamp base 1, a bulb shell 2, a lamp holder 3 and an LED light-emitting element 4 installed on the lamp holder 3, wherein the surface of the lamp holder 3 is provided with an active metal Zirconium coating, this active metal zirconium coating emits positive ion hot gas when it works and generates heat. The bulb 2 is filled with negative ion nitrogen gas 5 (shown by the dotted line in the figure), and the negative ion nitrogen gas 5 is the Nitrogen passes through the negative ion generator and is injected into the bulb 2 after being negatively charged. The negative ion nitrogen gas 5 realizes the cooling effect of the entire bulb through a chemical neutralization reaction with the positive ion hot gas emitted by the active metal zirconium coating. In order to meet the needs of different illumination brightness, the structure of the lamp holder 3 of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com