Micro-mechanics comb-typed gate capacitance top having electric tuning function

An electrical tuning and micro-mechanical technology, applied in the direction of gyro effect for speed measurement, gyroscope/steering sensing equipment, measurement device, etc., can solve the adjustment of the resonant frequency of the comb-shaped capacitive gyroscope, and the performance of the comb-shaped capacitive gyroscope cannot be effectively obtained. to improve the sensitivity of the

Active Publication Date: 2010-08-25

ZHEJIANG UNIV

View PDF5 Cites 42 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the traditional comb-gate capacitor gyroscope adopts a variable-area capacitor structure. The existing variable-area capacitor structure fails to adjust the resonant frequency of the comb-gate capacitor gyro in the driving or detection direction, making the comb-gate The performance of the capacitor gyroscope cannot be effectively improved

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

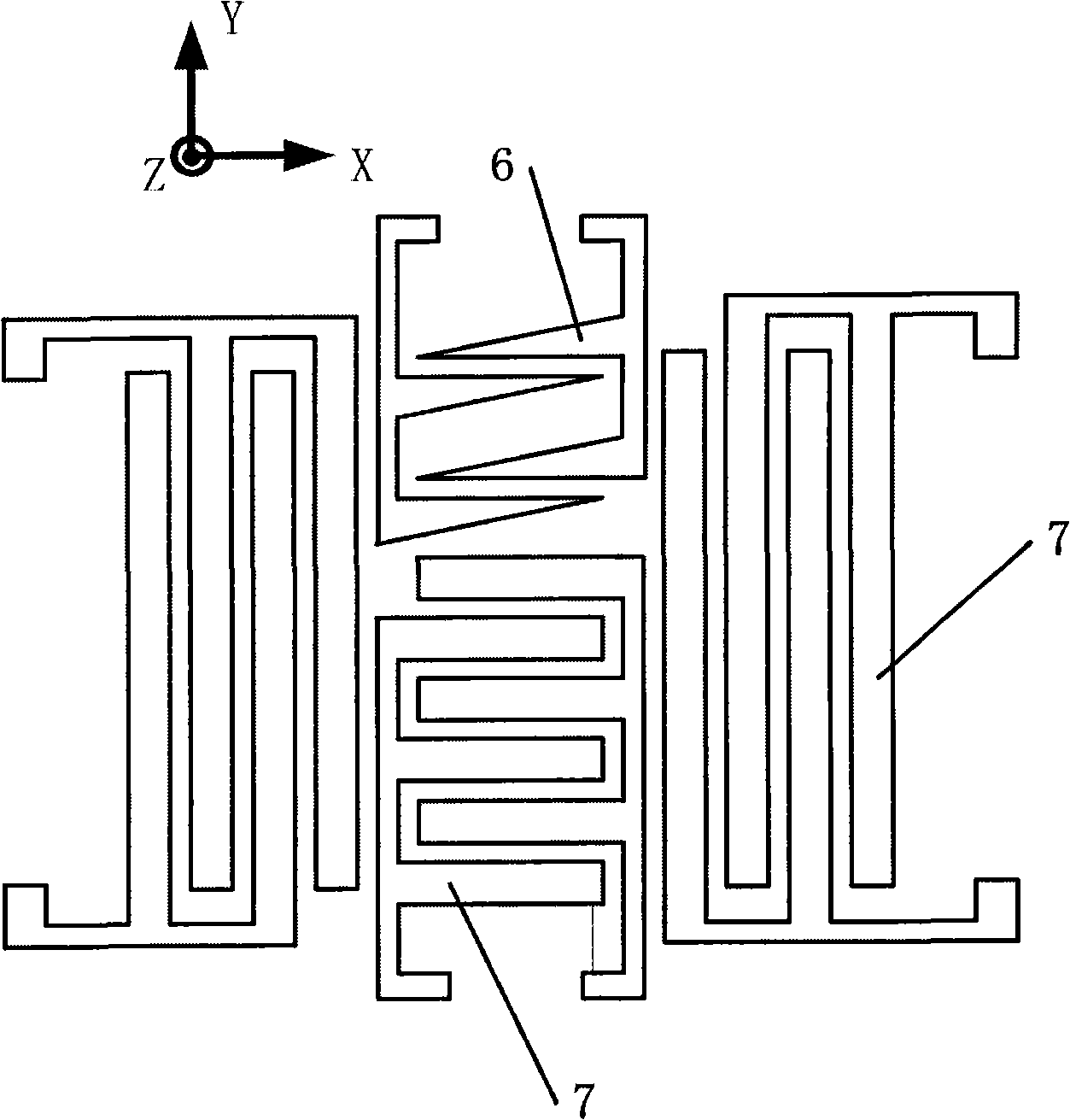

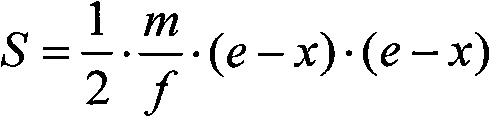

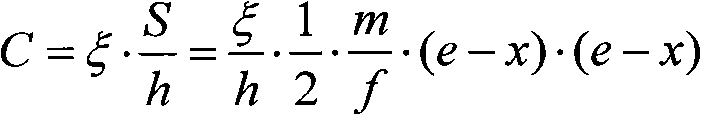

The invention discloses a micro-mechanics comb-typed gate capacitance top having an electric tuning function, and belongs to the field of micro-mechanics inertial sensors. An electric tuning variable area capacitor is distributed in a driving or detecting direction of the top; in each unit capacitor of the electric tuning variable area capacitor, the positive surface of a movable electrode is parallel to the positive surface of a fixed electrode, wherein the positive surface of the movable electrode is rectangular and the positive surface of the fixed electrode is triangular or saw tooth-shaped, or the positive surface of the movable electrode is triangular or saw tooth-shaped and the positive surface of the fixed electrode is rectangular, and the triangular positive surface and a long edge of the rectangular positive surface are overlapped. The top tunes a resonance frequency in the driving or detecting direction by the electric tuning variable area capacitor distributed in the driving or detecting direction of the top, so that the top devices in the same batch have similar properties; and the resonance frequencies in the driving and detecting directions are close or even equal, and the sensitivity of the top is greatly improved.

Description

technical field The invention relates to a micromechanical gyroscope and belongs to the field of micromechanical inertial sensors. Background technique A gyroscope is a sensor used to measure angular velocity and angular displacement, and is an important part of an inertial sensing unit. Since the first demonstration of the earth's rotation phenomenon by using the fixed axis of a high-speed rotating rigid body, the gyroscope has been developed for more than 100 years. Rotor gyroscopes, optical gyroscopes, and micromechanical gyroscopes have come out one after another. The sensitive mechanism of the vibrating micromechanical gyroscope is the Coriolis force, which is proportional to the rotation speed of the object, and the rotation speed of the object can be obtained by detecting the Coriolis force. There are many methods for detecting Coriolis force in the micromechanical gyro structure, among which capacitance detection is the most popular one at present, and there are tw...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01C19/56G01C19/5656G01C19/5719

Inventor 胡世昌金仲和张霞朱辉杰

Owner ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com