Micro-mechanics comb-typed gate capacitance top having electric tuning function

An electrical tuning and micro-mechanical technology, applied in the direction of gyro effect for speed measurement, gyroscope/steering sensing equipment, measuring device, etc., can solve the adjustment of the resonant frequency of the comb-shaped capacitive gyroscope, and the performance of the comb-shaped capacitive gyroscope cannot be effectively obtained. to improve the sensitivity of the

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

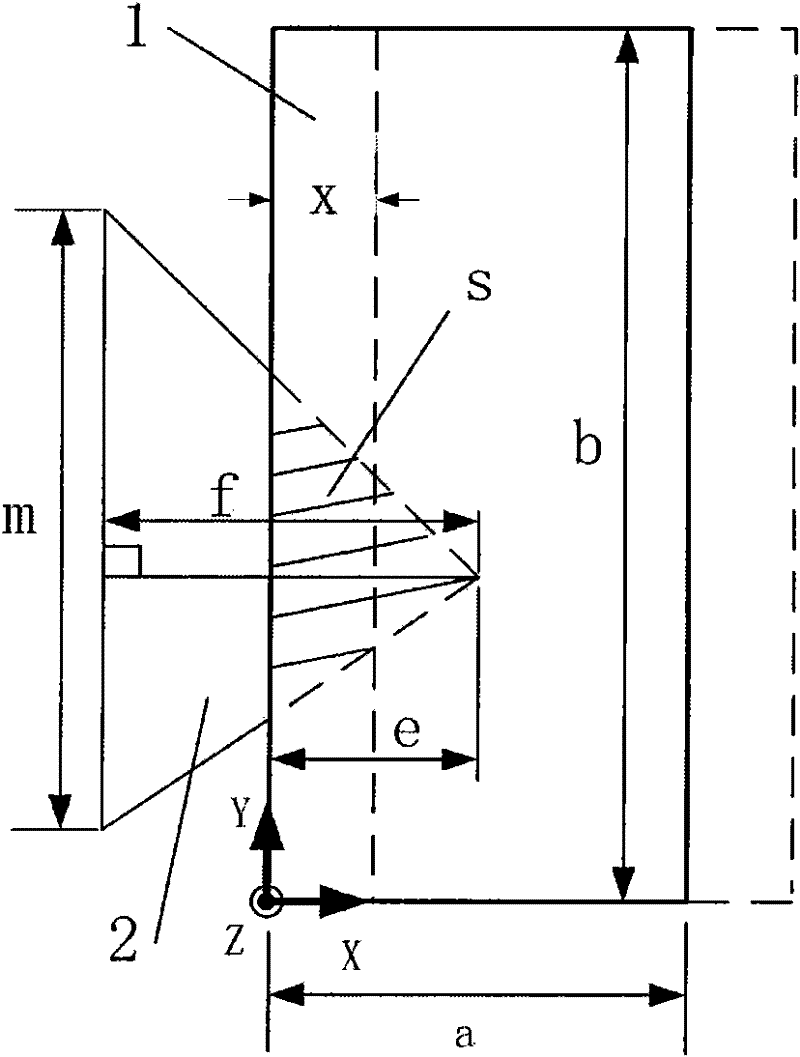

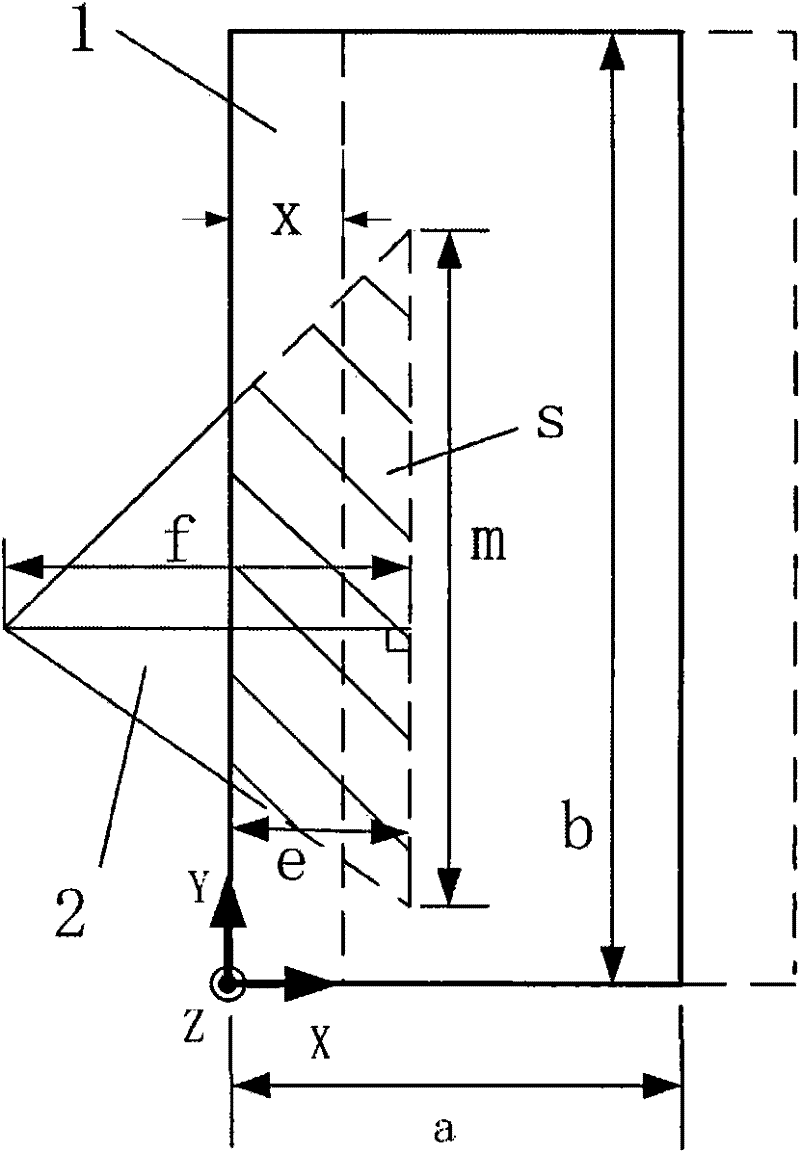

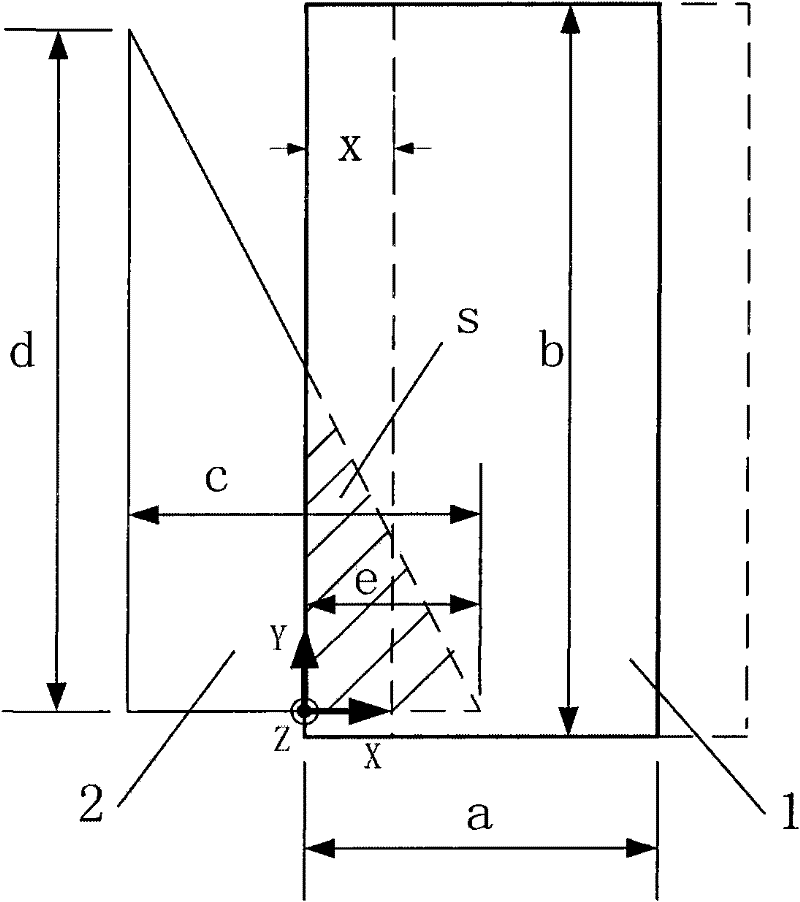

[0030] Such as Figure 1 to Figure 12 As shown, in the electrical tuning capacitor of the micromachined comb grid capacitor gyro with electrical tuning function in the present invention, the front surface of the unit movable electrode 1 refers to the surface facing the unit fixed electrode 2, and the front surface of the unit fixed electrode 2 The surface refers to the surface facing the unit movable electrode 1 . The front surface of each unit movable electrode 1 and the front surface of unit fixed electrode 2 are parallel to each other.

[0031] Such as Figure 1 to Figure 8 As shown, when the front surface of the unit movable electrode 1 is rectangular and the front surface of the unit fixed electrode 2 is triangular, the triangular front surface of the unit fixed electrode 2 only intersects with one long side of the rectangular front surface of the unit movable electrode 1. When the front surface of the unit movable electrode 1 is rectangular and the front surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com