Single piece device for storing, metering and mixing a powder with a diluent

A diluent, one-piece technology, used in the system field of mixtures, to solve problems such as distortion, system blockage, etc., to achieve improved quality control, high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

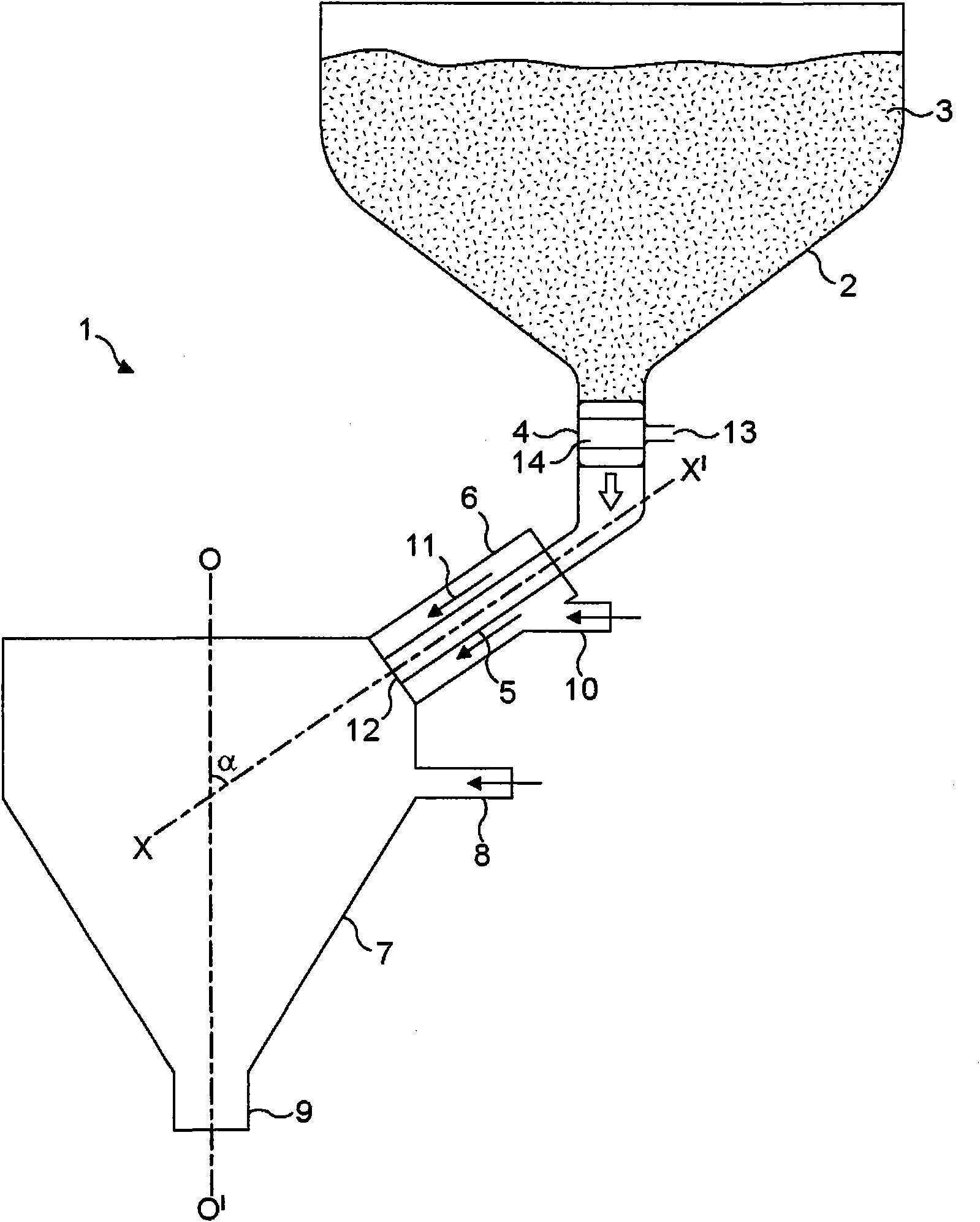

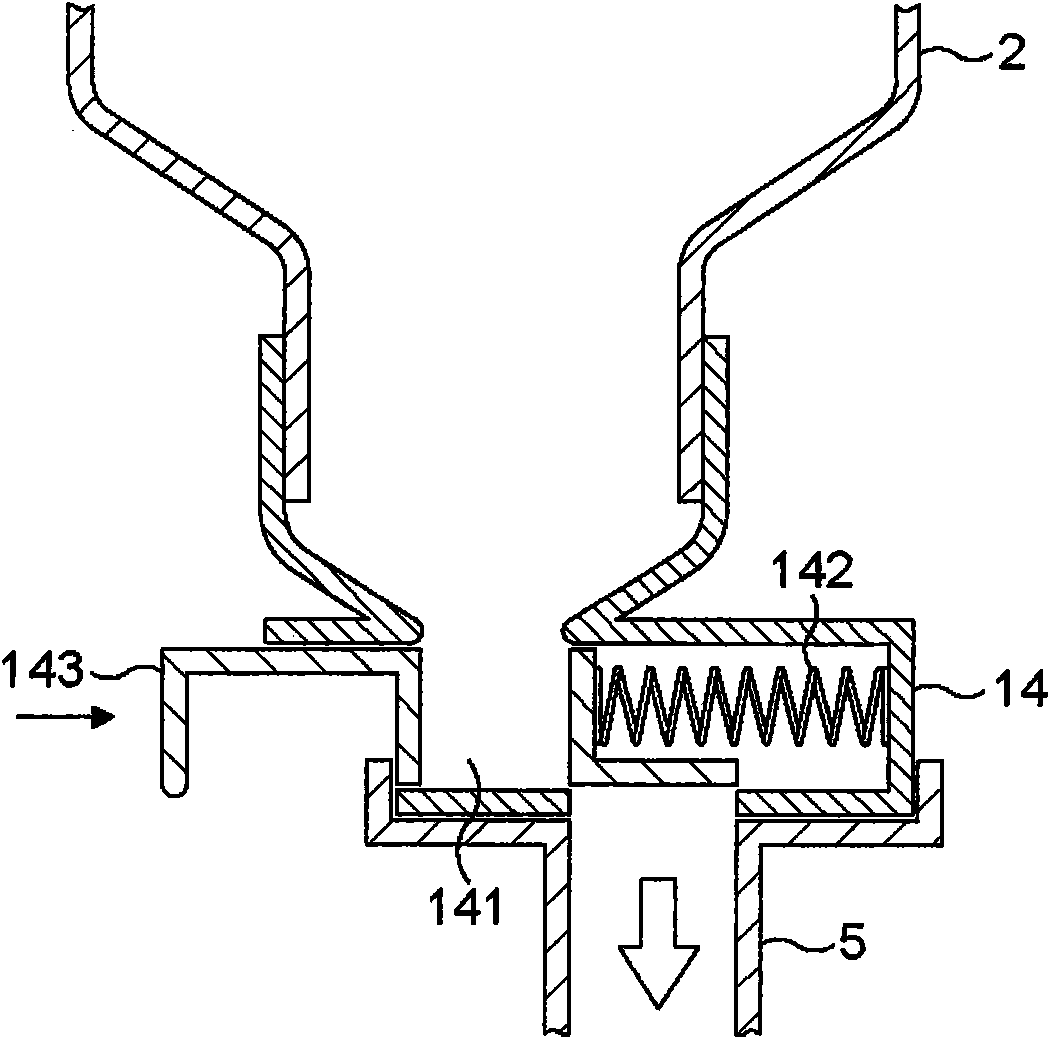

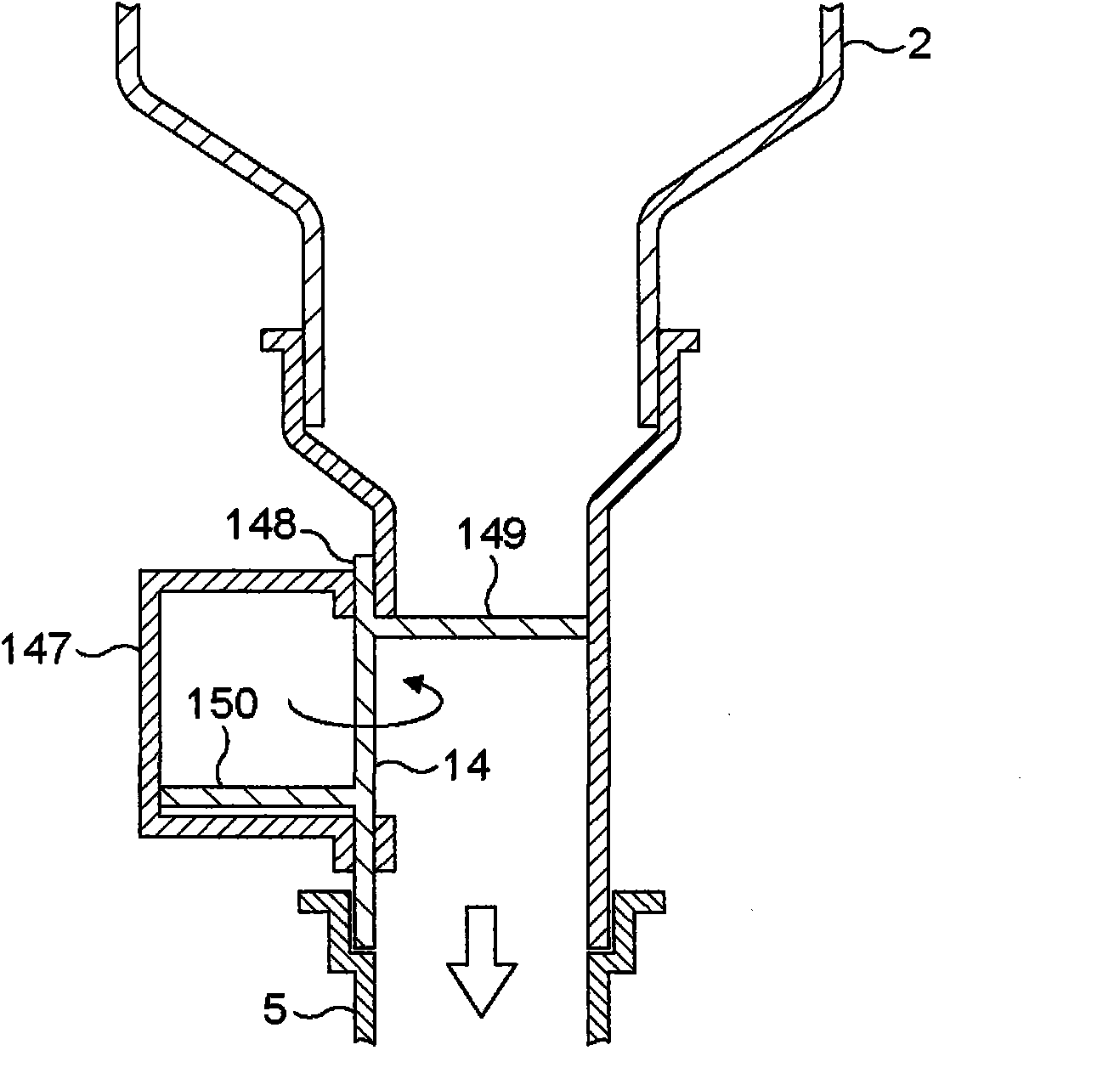

[0050] figure 1 A device 1 of the invention is shown. The device 1 comprises a container 2 filled with a powdered food ingredient 3 which falls by gravity onto a dosing system 4 comprising a dosing chamber 14 and a device enabling the dosing chamber to be driven by an external motor. Coupling mechanism 13. The pre-measured powder 3 is dosed in the dosing system 4 and conveyed via the powder line 5 into the bowl of the mixing chamber 7 where it is mixed with the pre-measured powder introduced through the diluent inlet 8 of the mixing chamber 7. Metered hot water is mixed and the diluent inlet is coupled to an external diluent source. The resulting mixture is distributed via food outlet 9 . The device 1 comprises a cylindrical air chamber 6 concentric with and surrounding the powder duct 5 . The purpose of this air chamber is to generate an air flow 11 around the powder duct outlet 12 exposed in the mixing chamber 7 . For this purpose, the air chamber is provided with an ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com