Slide die casting device for amorphous substance

A sliding, amorphous technology, applied in the field of sliding die-casting devices, can solve the problems of increasing defective molded products, degrading the accuracy of molded products, increasing processing time and cost, etc., so as to reduce defective products and reduce processing Effects of time, cost, and accuracy improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings.

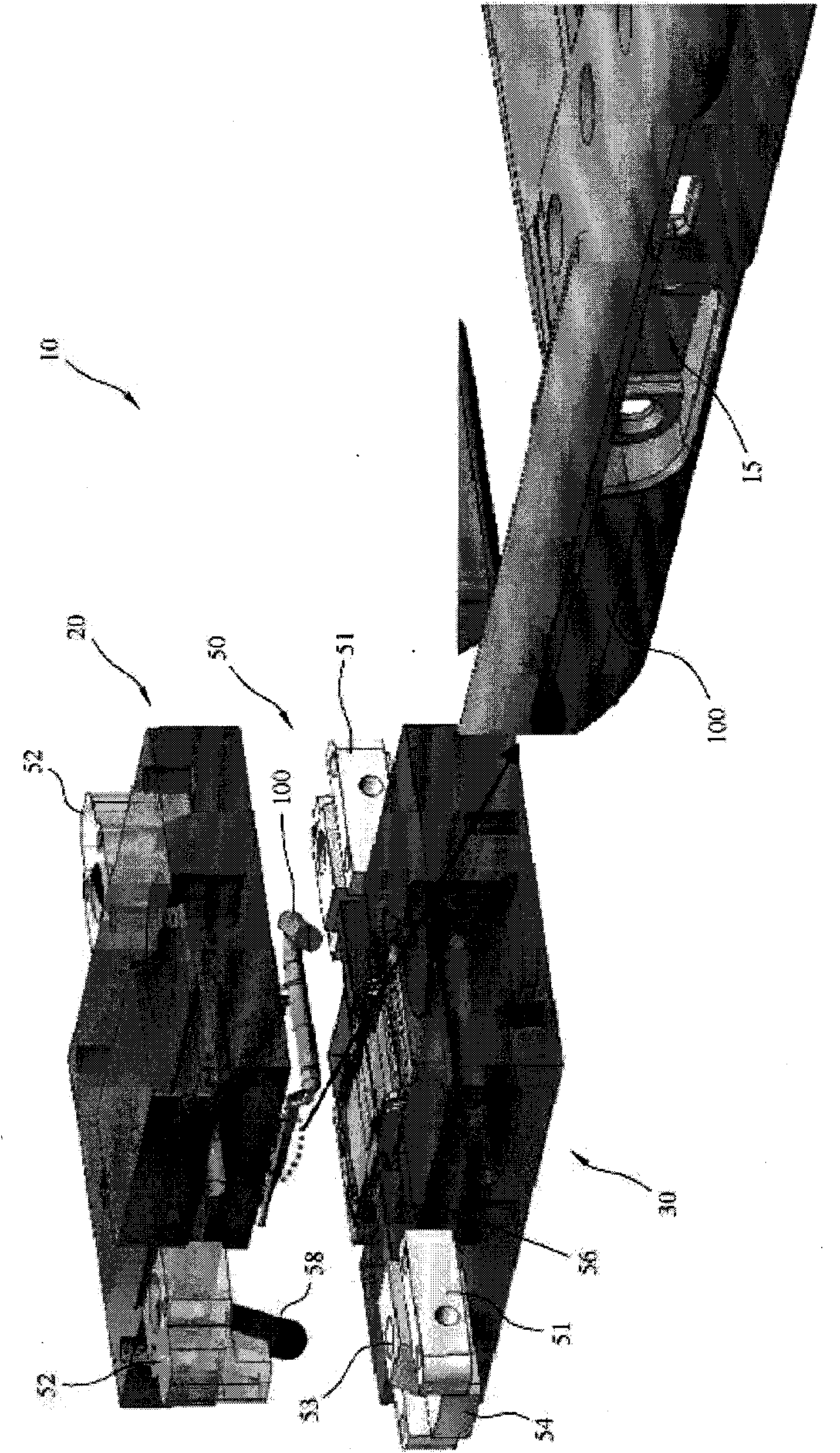

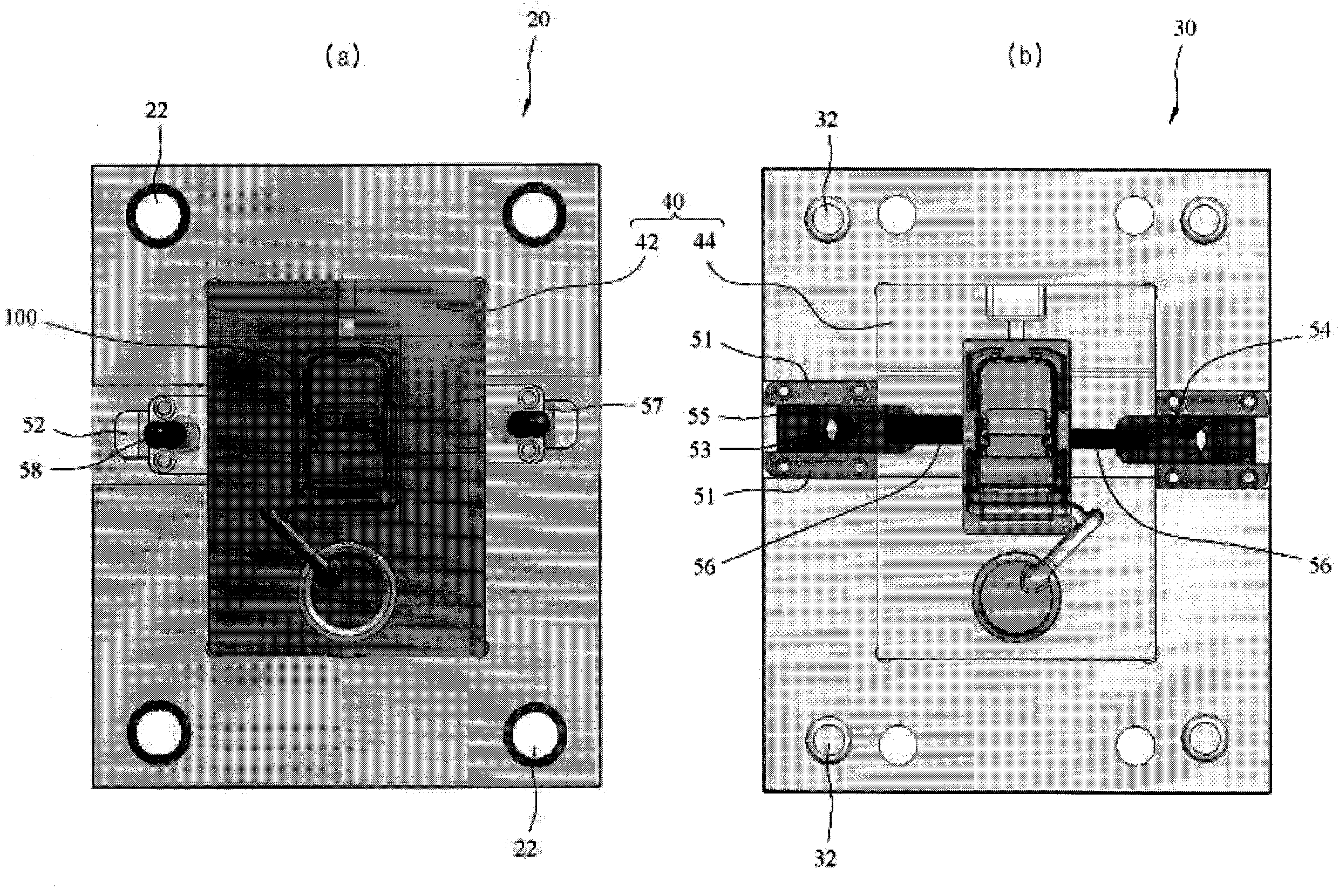

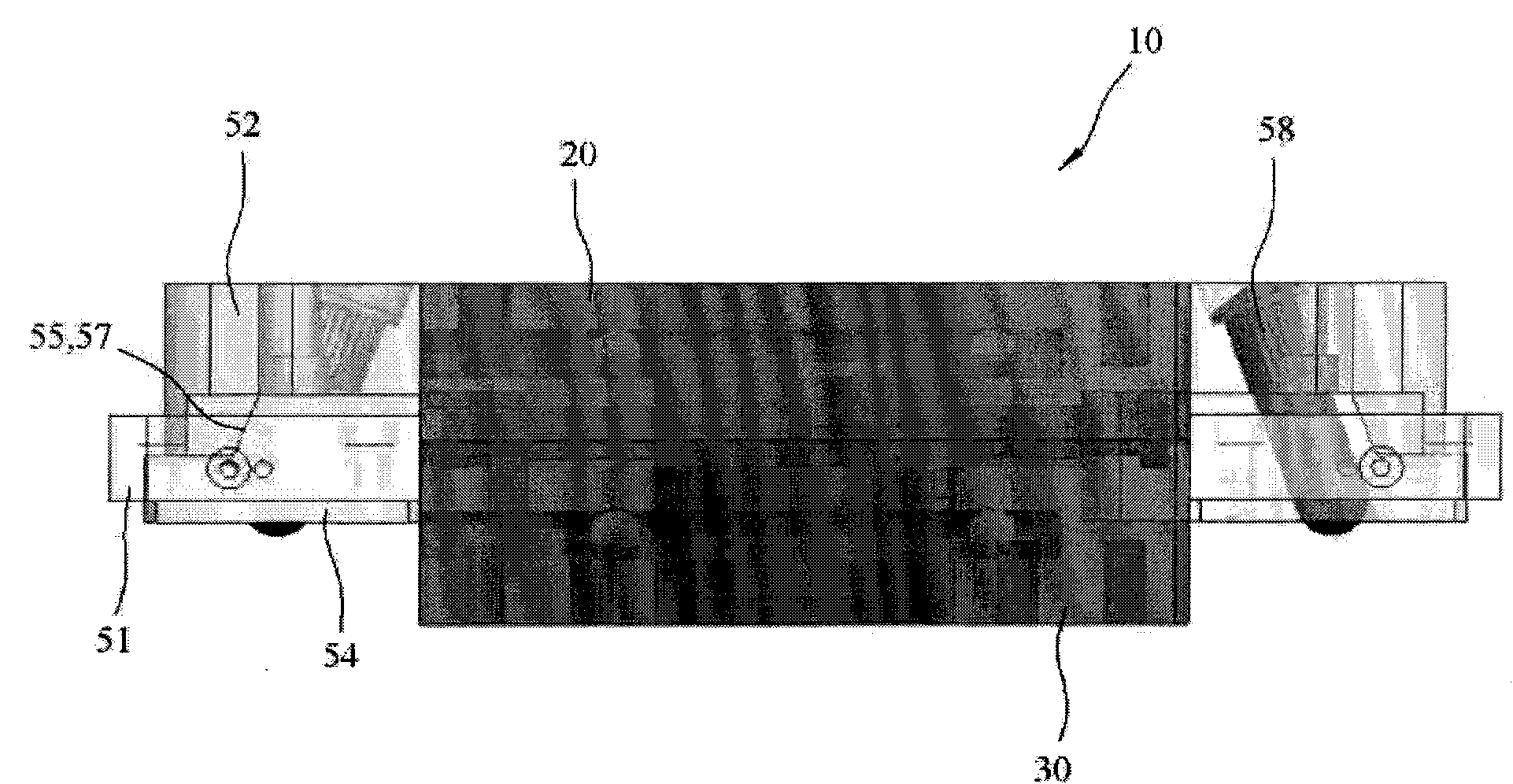

[0023] figure 1 is an exploded perspective view of a slide-type molding apparatus according to an embodiment of the present invention. Referring to the accompanying drawings, the sliding molding device includes: a molding unit 10; a fixed base 20 arranged in the upper part of the molding unit 10 in the form of a box; Movable base 30 in the form of a box; forming units 40 arranged in pairs, each forming unit 40 is arranged in the middle of fixed base 20 and movable base 30; a slide drive unit 50 with a hole formed on its side; and a workpiece 100 . Since the slide type molding apparatus can simultaneously machine holes in the side of the molded product during molding, the accuracy of the product can be improved. In addition, processing time and cost can be reduced, and defective molded products caused by secondary processing can also b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com