Cylinder shell anti-loosening device of combing machine

A comber and casing technology, applied in the direction of comber, textile and papermaking, fiber processing, etc., can solve the problems of easy vibration of brakes, large centrifugal force, heavy weight, etc., to achieve high-speed operation, maintain stability, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

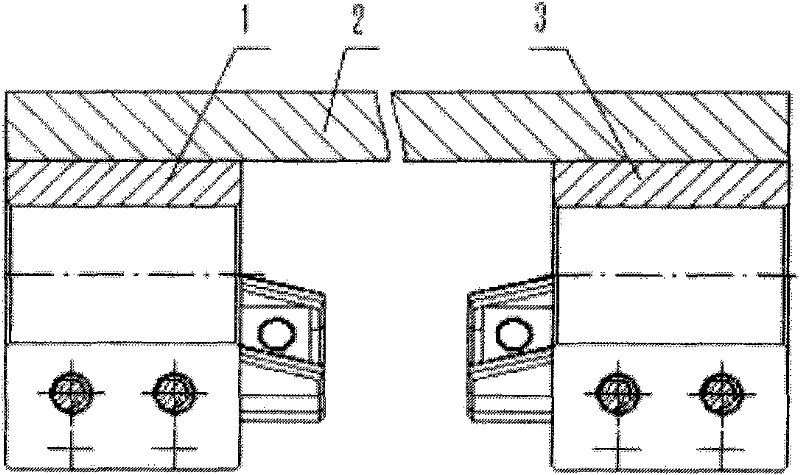

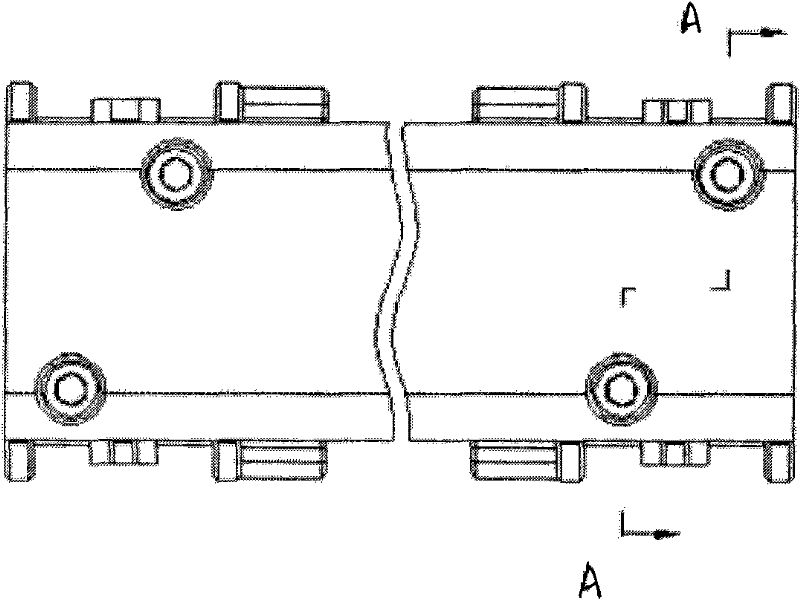

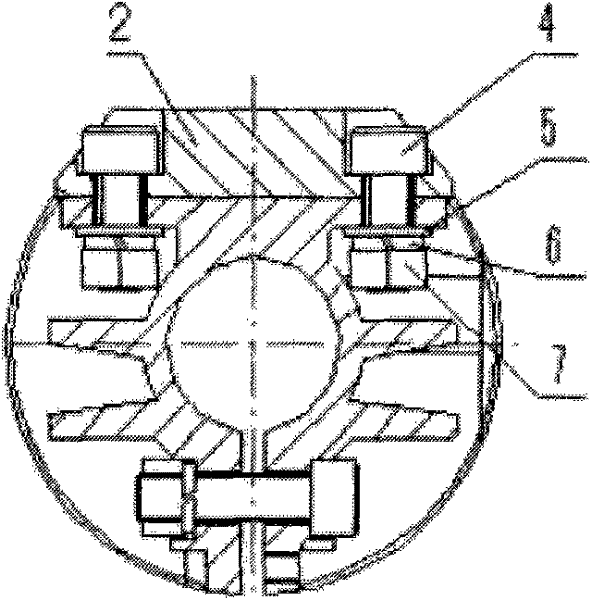

[0009] An anti-loosening device for a comber cylinder housing, which includes a left cylinder housing 1, a balance plate 2, a right cylinder housing 3, screws 4, flat washers 5, anti-loose washers 6 and nuts 7, left tin The material of the forest shell 1 is aluminum casting, the material of the balance plate 2 is steel, the material of the right cylinder shell 3 is aluminum casting, and the left cylinder shell 1, the right cylinder shell 3 and the balance plate 2 are arranged There is glue, the left cylinder shell 1 and the balance plate 2 are connected by two sets of screws 4, flat washers 5, lock washers 6, and nuts 7, the screws 4 and nuts 7 are connected by thread glue, the balance plate 2 and the right cylinder The housing 3 is connected by two sets of screws 4, flat washers 5, lock washers 6, and nuts 7, and the screws 4 and nuts 7 are connected by thread glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com