Low windage resistance mitre gate

A technology of miter gates and air resistance, applied in the direction of lift valves, valve details, engine components, etc., can solve the problems of complex and difficult production processes, and the incompatibility of miter gate parts, and achieve simple production processes and low manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Now in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

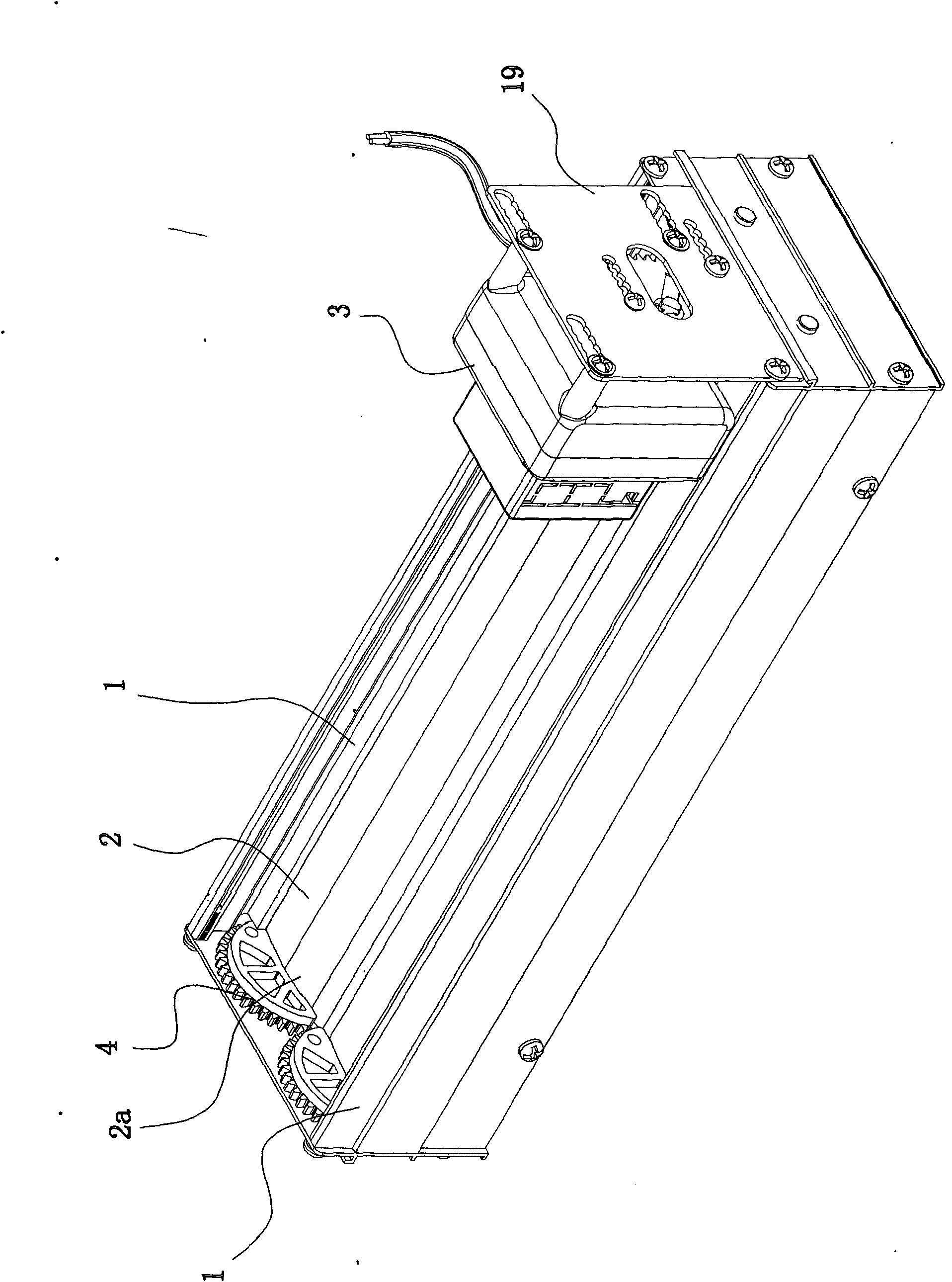

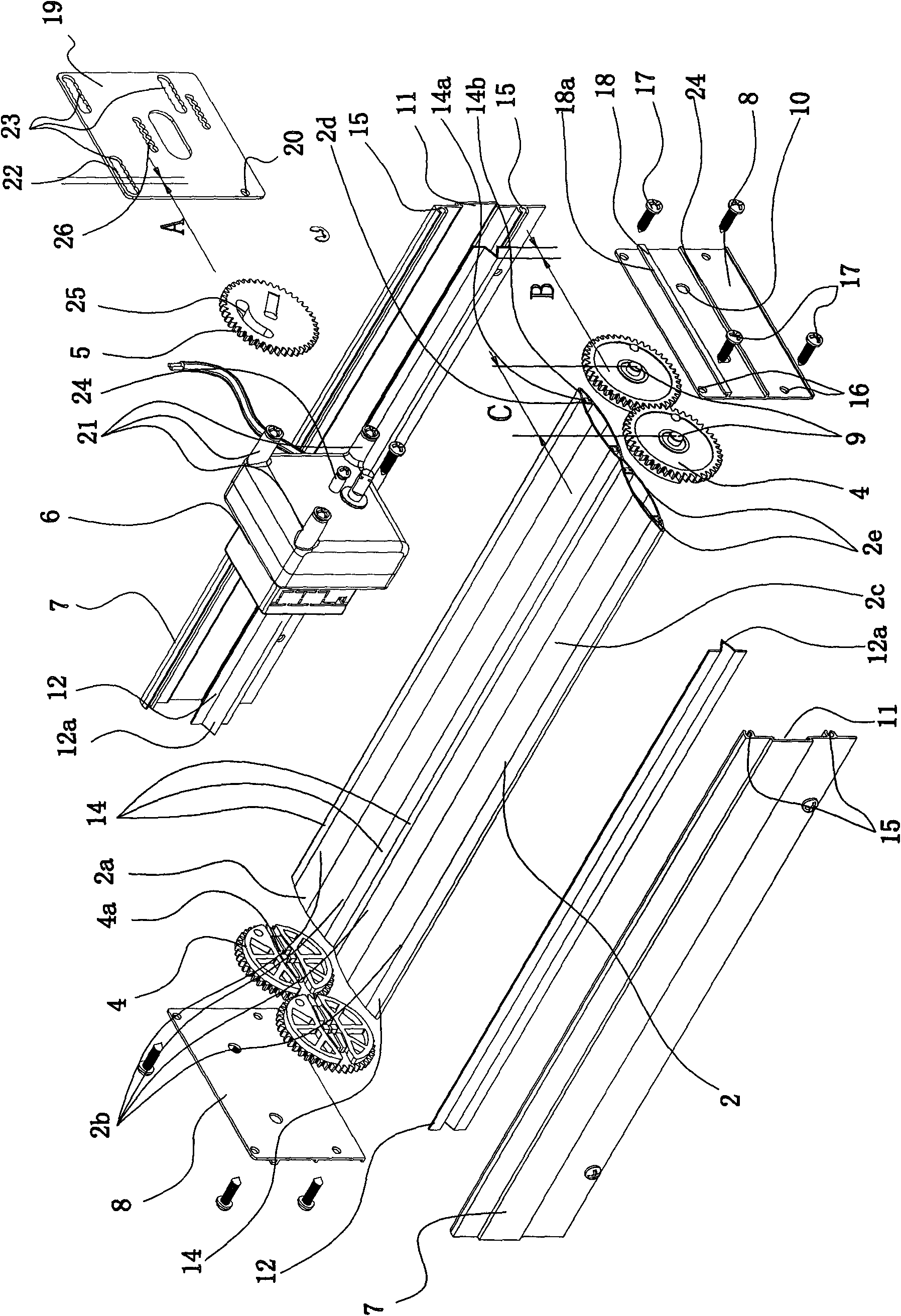

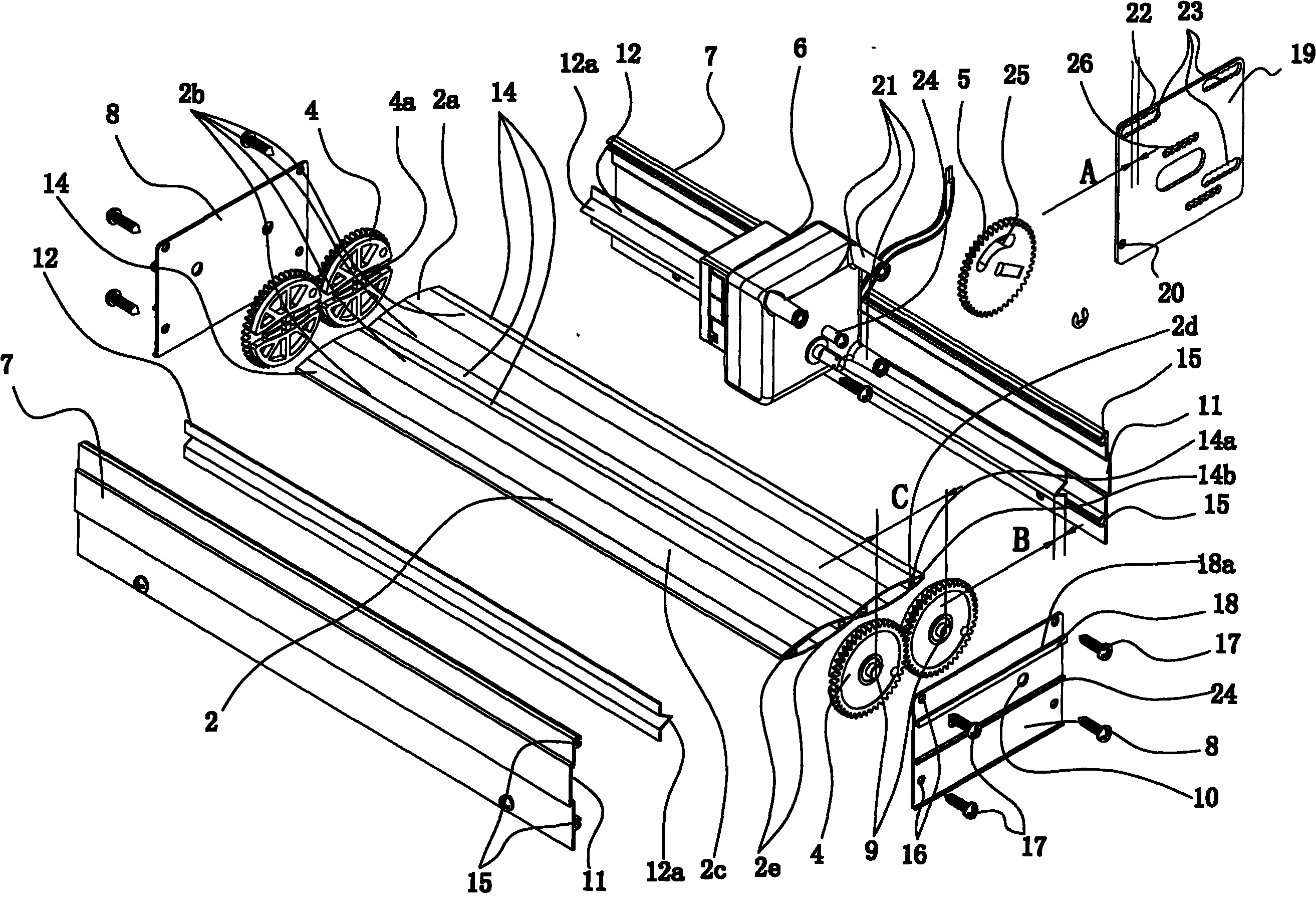

[0014] As shown in the figure, the present invention includes a square frame-shaped valve body 1, more than one blade 2 arranged in the square frame-shaped valve body 1, and a power transmission mechanism 3 for driving the rotation of the blades 2. The power transmission mechanism 3 includes 2 The vane gear 4 at the end 2a, the drive gear 5 that drives the vane gear 4 to rotate, the power device 6 that drives the drive gear 5 to rotate, the square frame-shaped valve body 1 includes two long side frames 7, fixed on the two long side frames 7 The two short side frames 8 at the end, the blade gear 4 is connected to the shaft hole 10 of the short side frame 8 of the square valve body 1 through the rotation of the shaft 9, and the long side frame 7 is cut from the long side frame aluminum alloy profile. The short side frame 8 is cut from the short side frame al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com