Furnace end for outdoor heater

A heater and outdoor technology, applied in burners, gas fuel burners, combustion methods, etc., can solve problems such as high CO content, explosion, user injury, etc., to reduce the generation of CO and the probability of tempering The effect of reducing and slowing down the impact force of backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the drawings and specific embodiments.

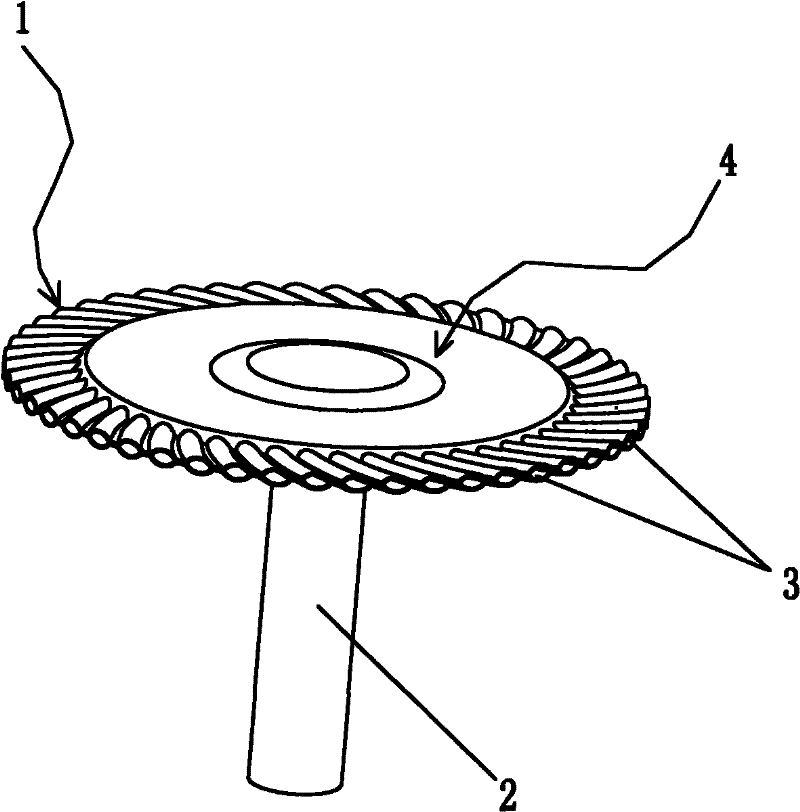

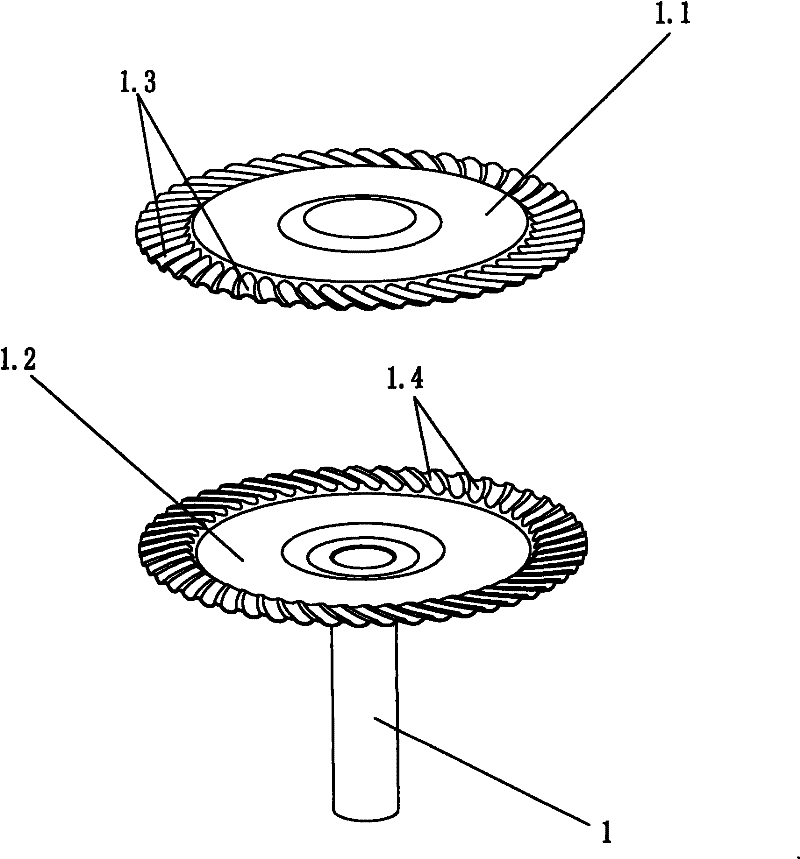

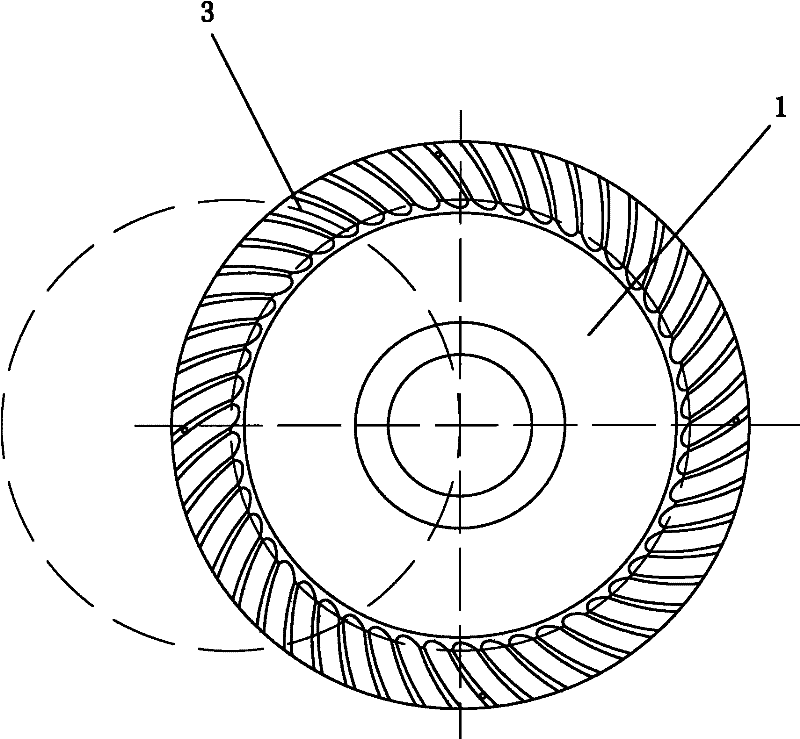

[0014] Such as figure 1 , figure 2 As shown, the present invention is used for the stove head of an outdoor heater. It includes a stove plate 1 composed of an upper stove plate 1.1 and a lower stove plate 1.2. Below the stove plate 1 is an intake pipe 2 for gas to enter, and the stove plate 1 There are a number of burning holes 3 radially distributed along the circumference of the hob 1, the middle part of the upper hob 1.1 is provided with an upward depression, the middle part of the lower hob 1.2 is provided with a downward depression, and the upper furnace After the pan 1.1 and the lower furnace pan 1.2 are fixedly connected together by spot welding or bolts, the depression on the upper furnace pan 1.1 and the depression on the lower furnace pan 1.2 constitute the gas gathering area 4, and the air inlet pipe 2 is connected with the gas gathering area 4 for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com