Integrated bioreactor and its reaction process

A bioreactor and reaction technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of poor simultaneous removal of nitrogen and phosphorus, high energy consumption, carbon source Insufficient and other problems, to achieve the effect of improving land utilization, high denitrification and phosphorus removal efficiency, and reducing sludge discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

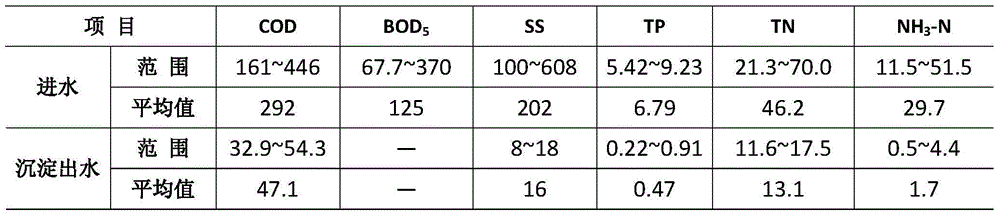

Embodiment 1

[0047] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

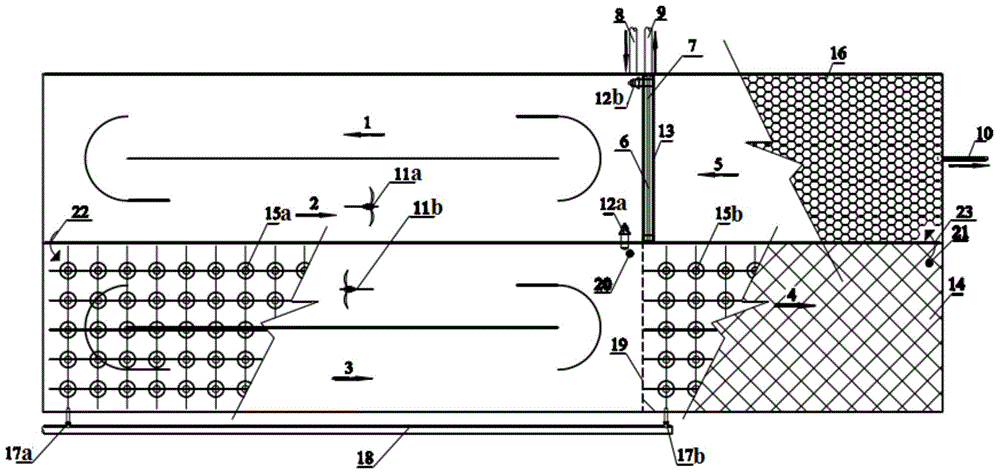

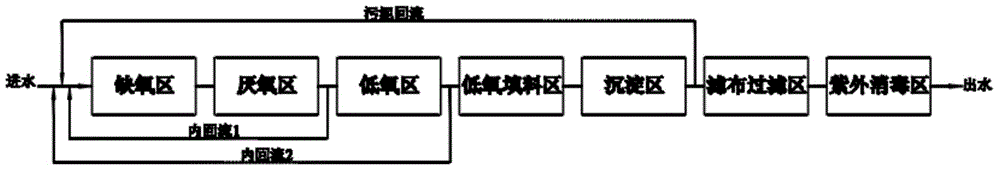

[0048] Depend on figure 1 As shown, the integrated bioreactor includes anoxic zone 1, anaerobic zone 2, hypoxic zone 3, hypoxic packing zone 4, sedimentation zone 5, filter cloth filtration zone 6 and disinfection zone 7;

[0049] An anoxic zone 1 side wall is provided with a water inlet pipe 8, a first partition wall is set between the anoxic zone 1 and anaerobic zone 2, and a first diversion wall is set at a position away from the two ends of the first partition wall, and in the anaerobic zone 2 Set the first frequency conversion submersible flowmaker 11a in the water flow direction of the inner and anoxic zone 1;

[0050] The anaerobic zone 2 communicates with the hypoxic zone 3 through the water hole 22 arranged on the side wall. In the hypoxic zone 3, a second partition wall is arranged parallel to the first partition wall, and at a position away ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com