Plate for noise barrier and manufacturing method thereof

A production method and technology of sound barrier, which are applied in the direction of sound-producing equipment and instruments, can solve the problems of short service life, high material cost and construction cost, poor fire performance, etc., and achieve good noise reduction effect, easy construction and maintenance, and low cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

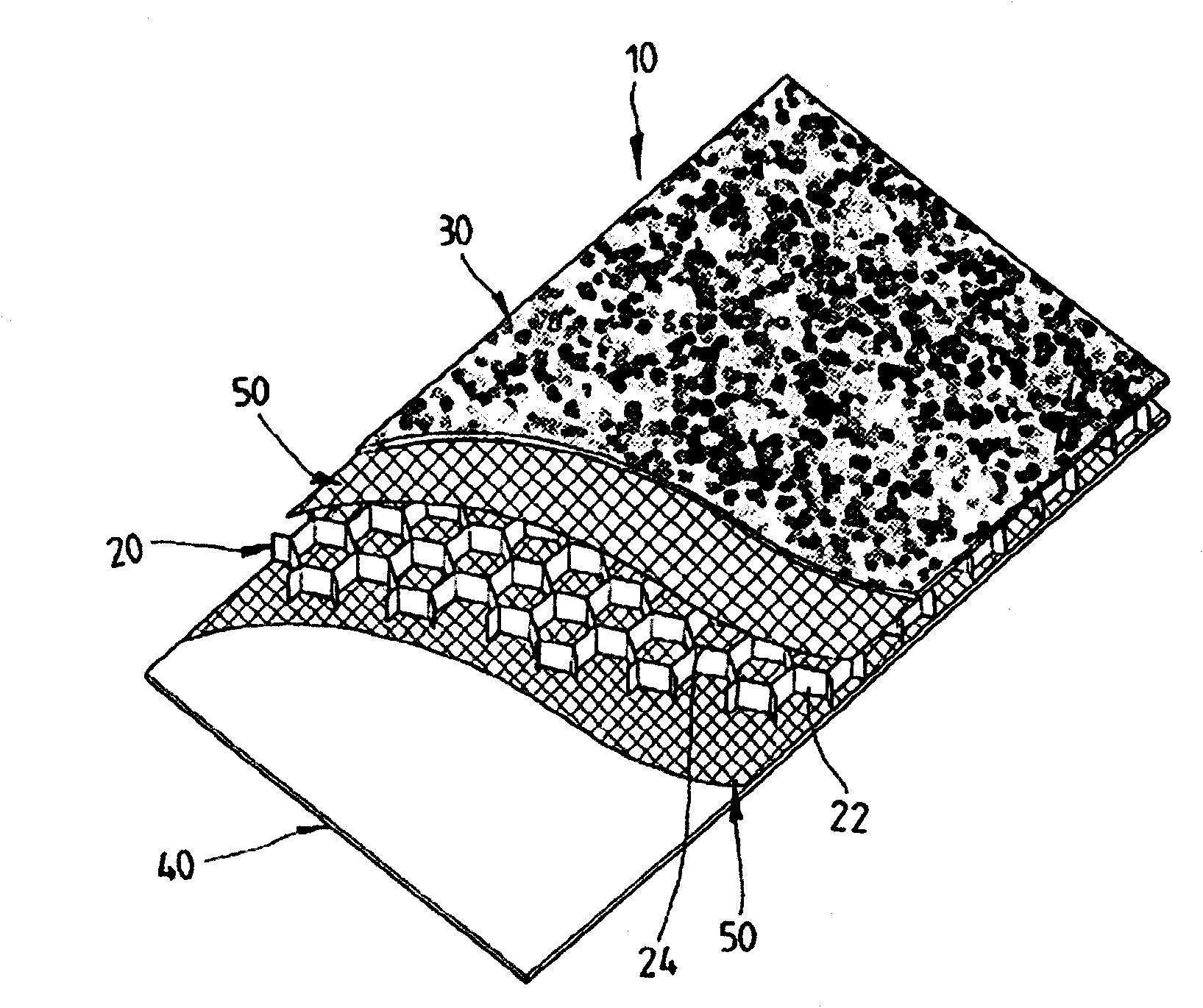

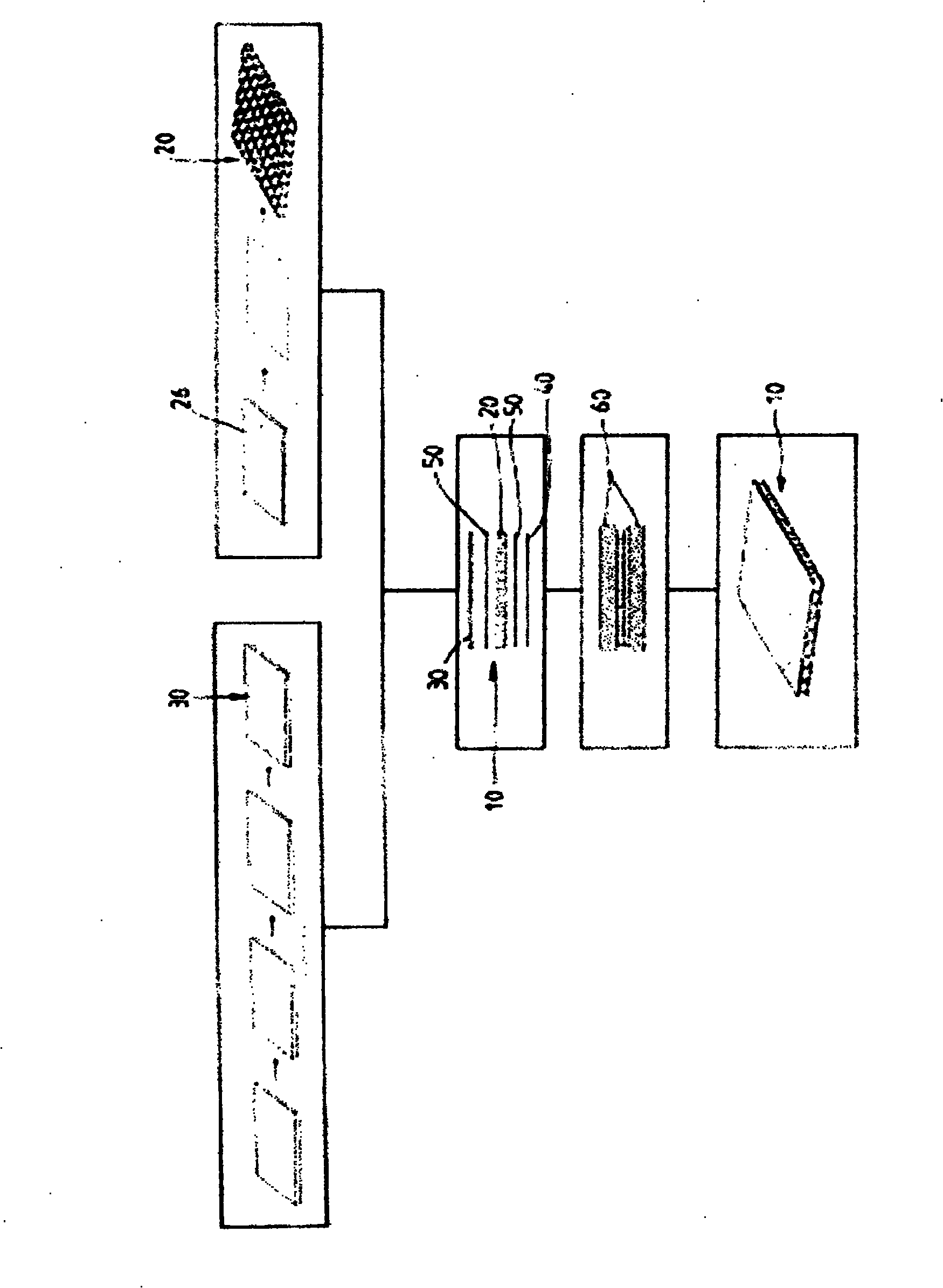

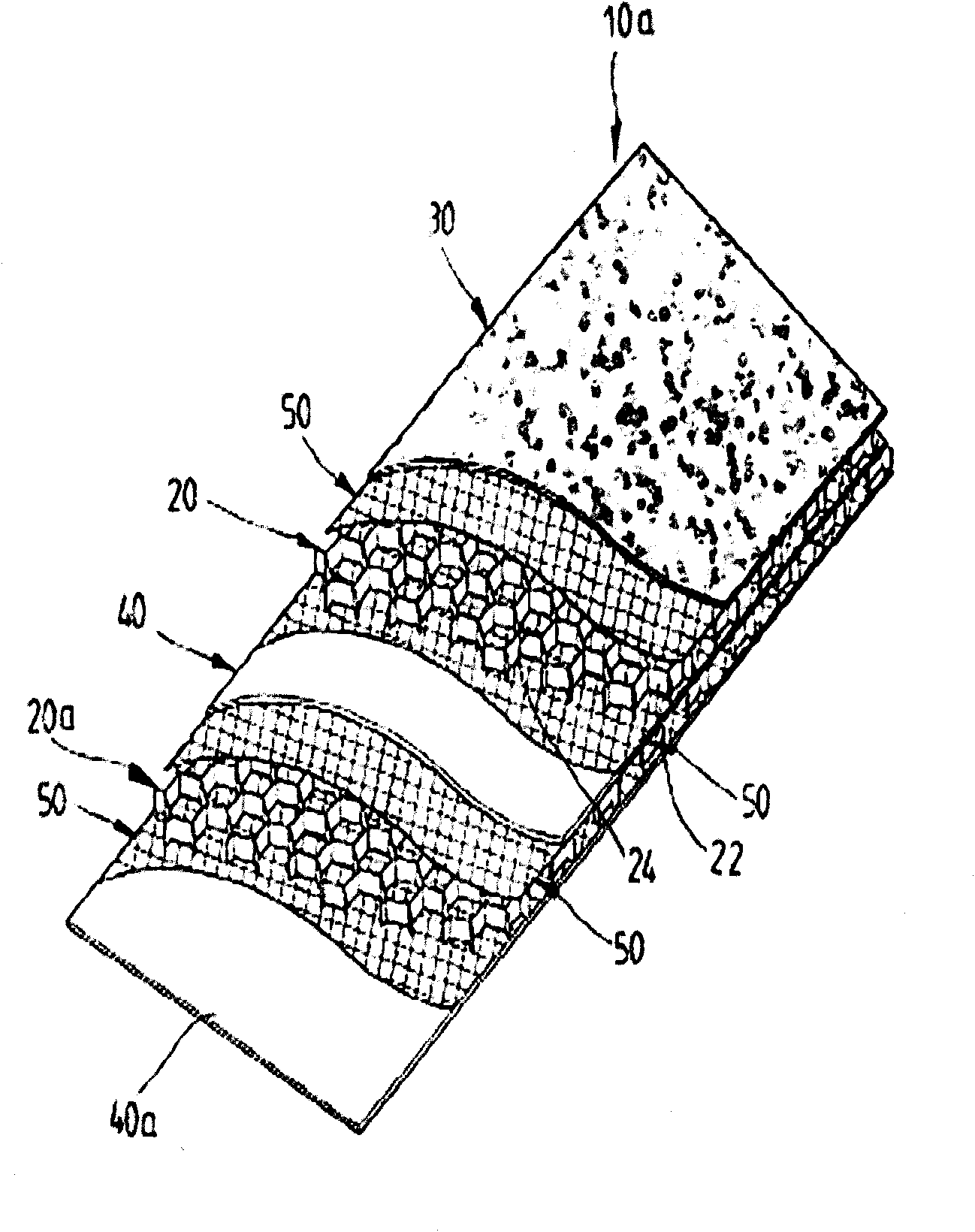

[0041] The sheet material for the sound barrier of the present invention is that the aluminum honeycomb is made of a thin aluminum plate into a hexagonal honeycomb shape, and the foamed aluminum with a lot of pores with sound-absorbing function is bonded together through an adhesive film, also known as foamed aluminum, in the aluminum honeycomb On the other side, the adhesive film is bonded to other plate materials such as aluminum plates or other metal plates or glass fiber reinforced plastics with sound insulation functions to form a new type of composite sound barrier plate product. It is characterized in that aluminum honeycomb and aluminum foam are combined together, and it is a new type of sheet product for sound barriers.

[0042] The plate material for the sound barrier of the present invention is a hexagonal honeycomb-shaped aluminum honeycomb made of aluminum thin plates, which are respectively compounded with the above-mentioned foamed aluminum sound-absorbing board ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com