Non-contact type power supply device for supplying power to automatic doffer

An automatic doffing and power supply device technology, applied in the direction of circuit devices, electrical components, electromagnetic wave systems, etc., can solve the problems of inconvenient operation of the doffing machine trolley, equipment contact or entanglement, etc., to ensure safe and stable operation, reduce loss, and ensure reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in detail as follows in conjunction with accompanying drawing and embodiment:

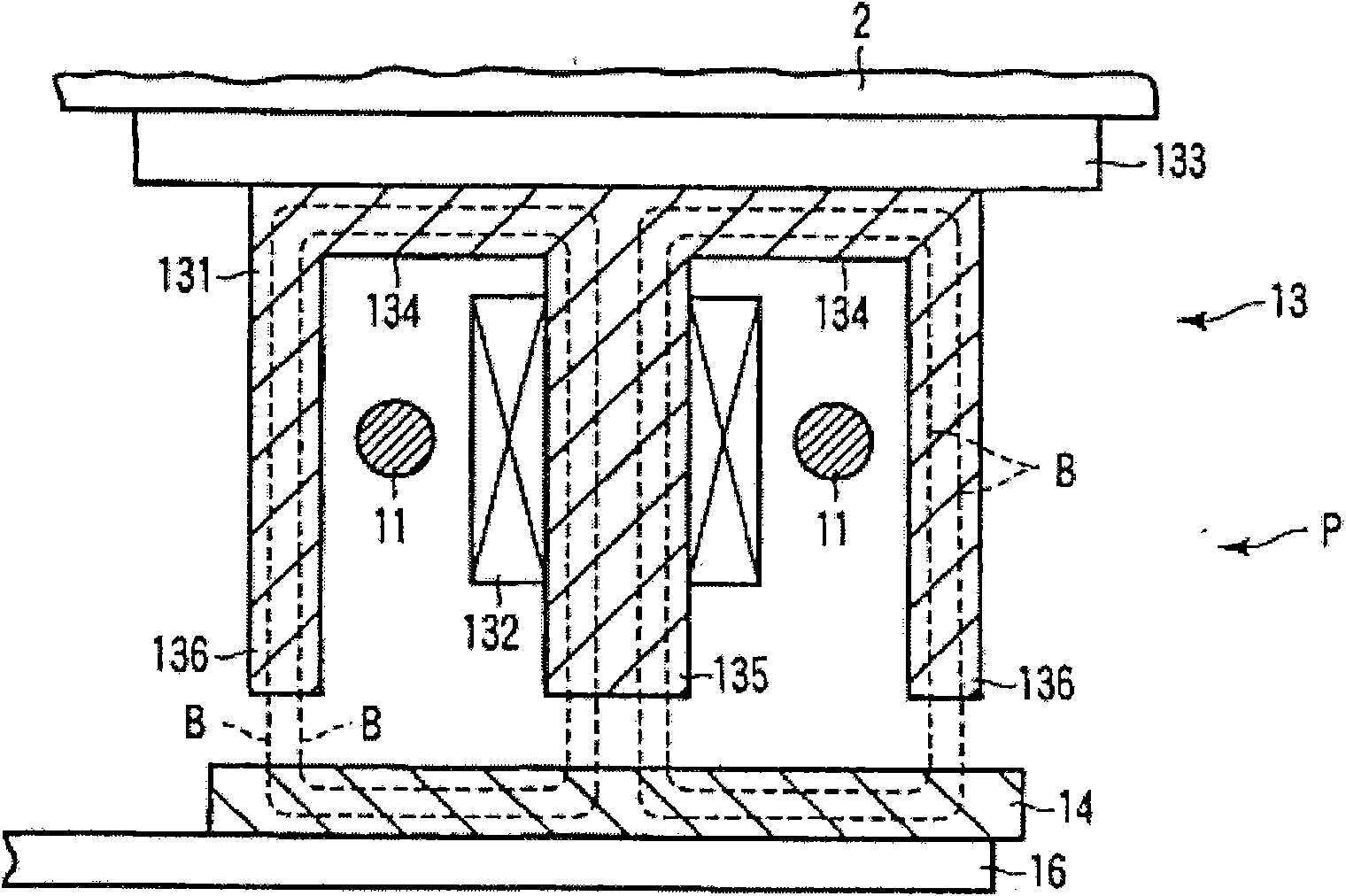

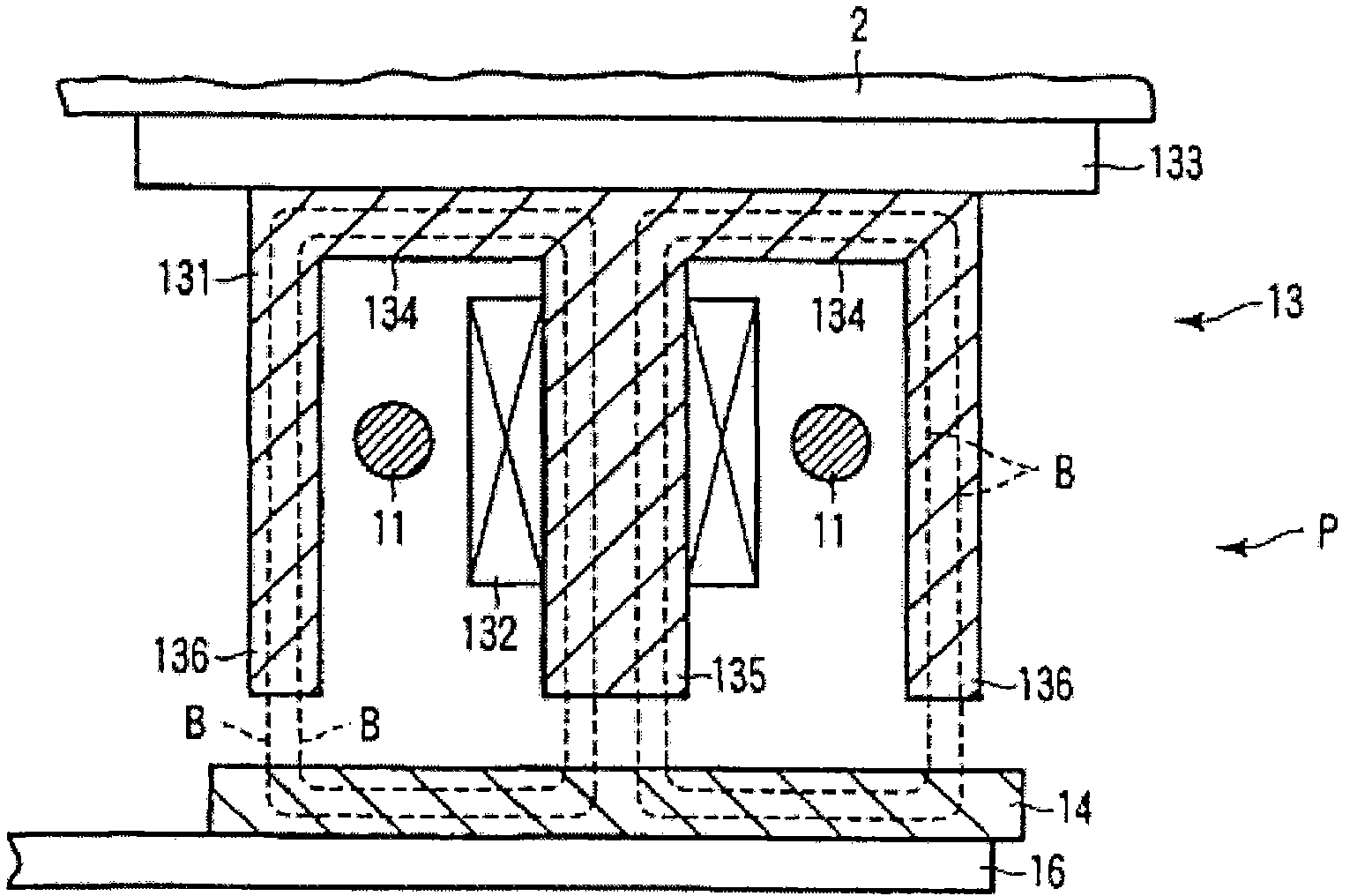

[0016] The invention provides a non-contact power supply device for supplying power to an automatic doffing machine, such as figure 1 As shown, it includes a power supply line 11, a commercial frequency power supply (not shown in the figure), a power receiving unit 13 composed of an iron core 131, a coil 132 and a magnetic body 14; the power supply line 11 is composed of two parallel and connected at both ends Composed of cables, the bracket is erected on a path parallel to the track of the automatic doffing machine, and the length of the power supply line 11 is equal to the track; the power frequency power supply is set on the ground on one side of the spinning machine and connected to the lead-out end of the power supply line 11; the iron The core 131 is composed of an integrally formed top edge 134, a center column 135 and two center columns 136 perpendi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com