Rail carbon brush device of brush motor

A brushed motor and carbon brush technology, applied in electromechanical devices, electrical components, etc., can solve the problems of carbon brush instability, increased cost, increased electrical noise, etc., and achieve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

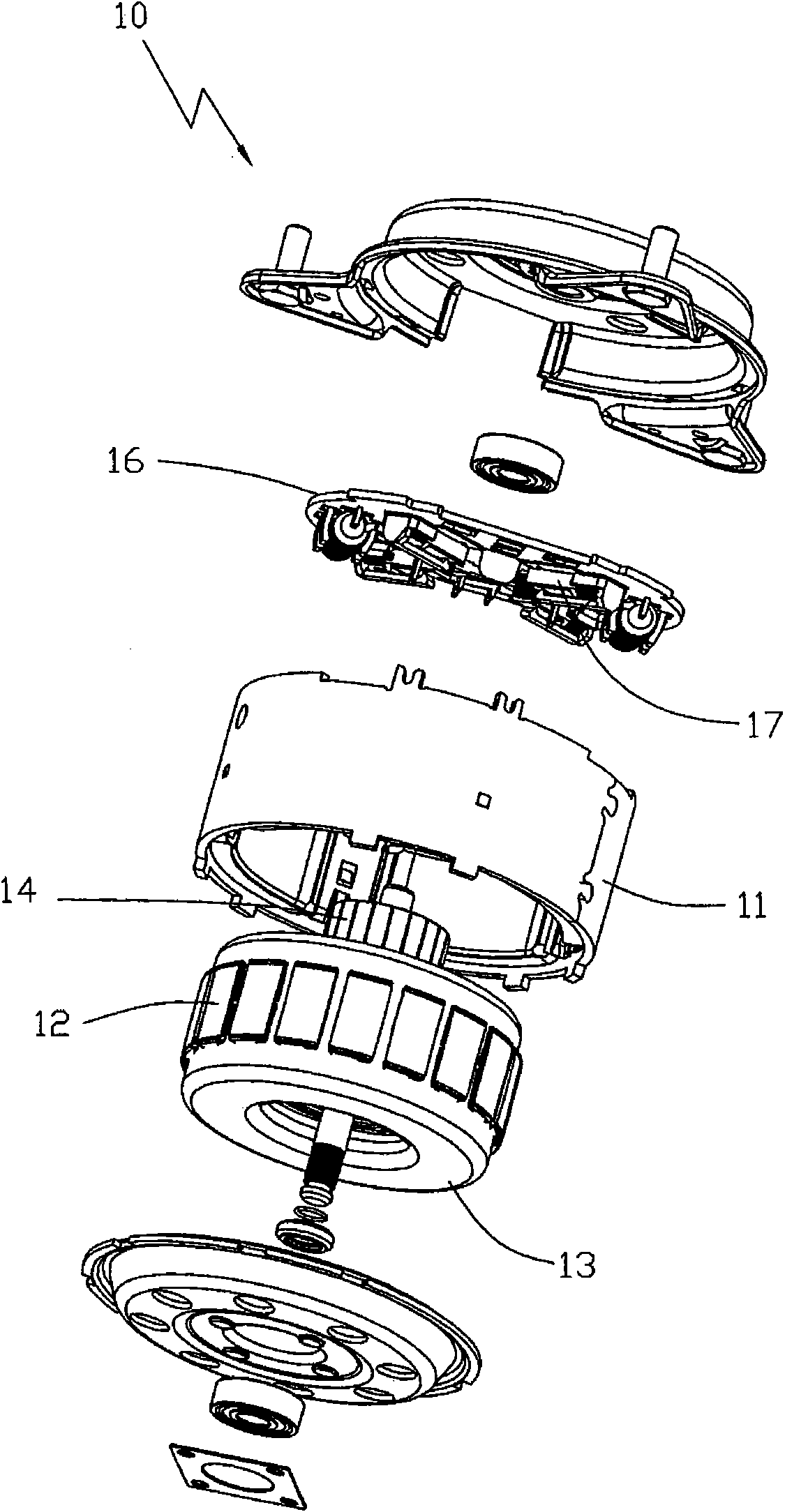

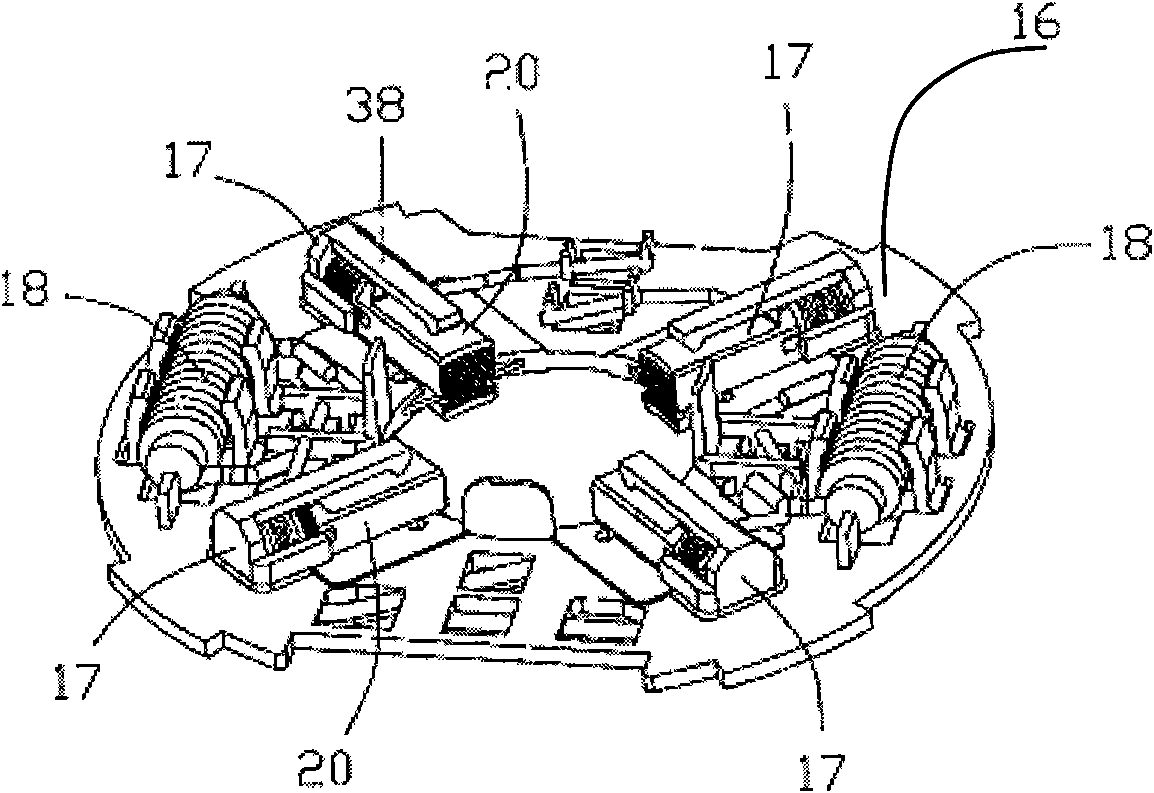

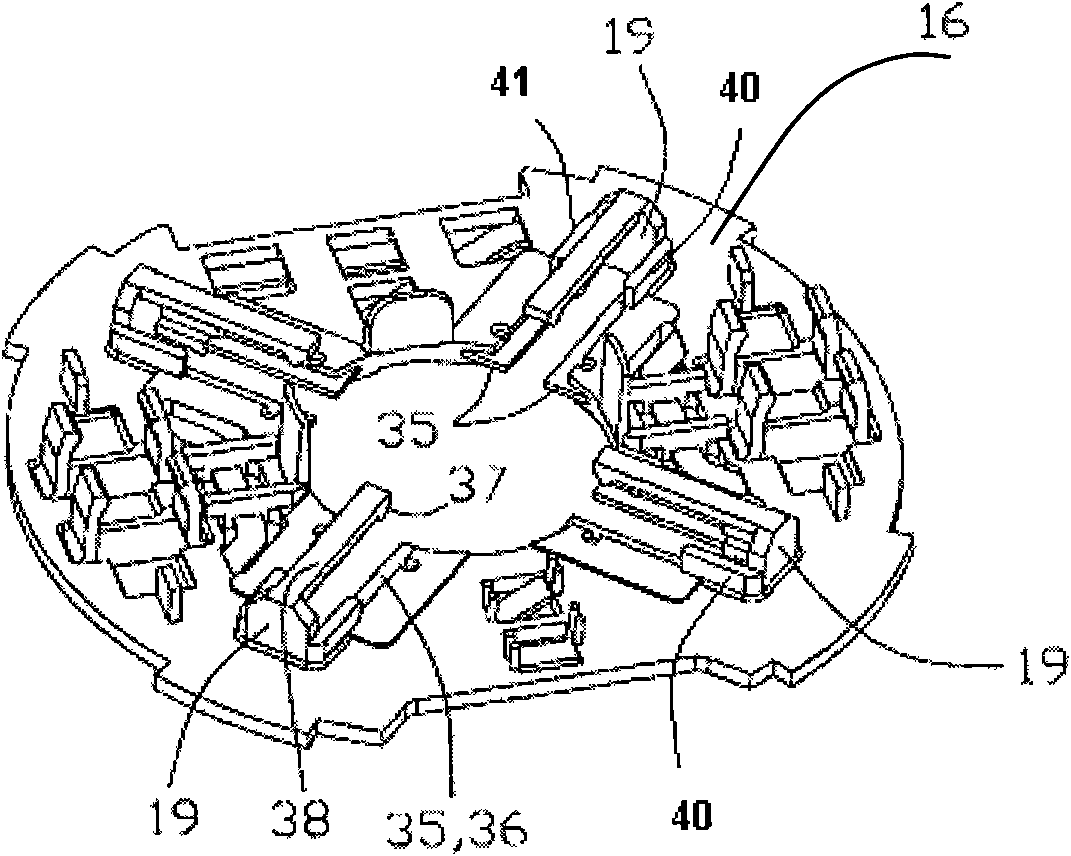

[0022] figure 1 It is an exploded schematic diagram of a PMDC motor 10 in a preferred embodiment of the present invention. The motor 10 includes a stator 11, a rotor 12 and a carbon brush device, the stator 11 includes a permanent magnet pole, the rotor 12 includes a winding 13 and a commutator 14, and the carbon brush device transfers electric energy from the motor terminal (not shown in the figure) through the commutator. shown) is transferred to winding 13. The carbon brush device includes a carbon brush base plate 16 and a plurality of carbon brush assemblies 17 supported by the carbon brush base plate 16, and the carbon brush base plate 16 is fixedly installed on the end cover of the foundation. Each carbon brush assembly 17 includes a carbon brush, a guide system in the form of a guide rail, and a spring, wherein the guide system is used to guide the carbon brush to slide toward the commutator, and the spring elastically drives the carbon brush to slide toward the commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com