Non-contact measurement apparatus and method

A non-contact, imaging device technology, applied in the direction of measuring devices, camera devices, optical devices, etc., can solve the problems of high computing requirements, useless data and sensitivity to lighting artifacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

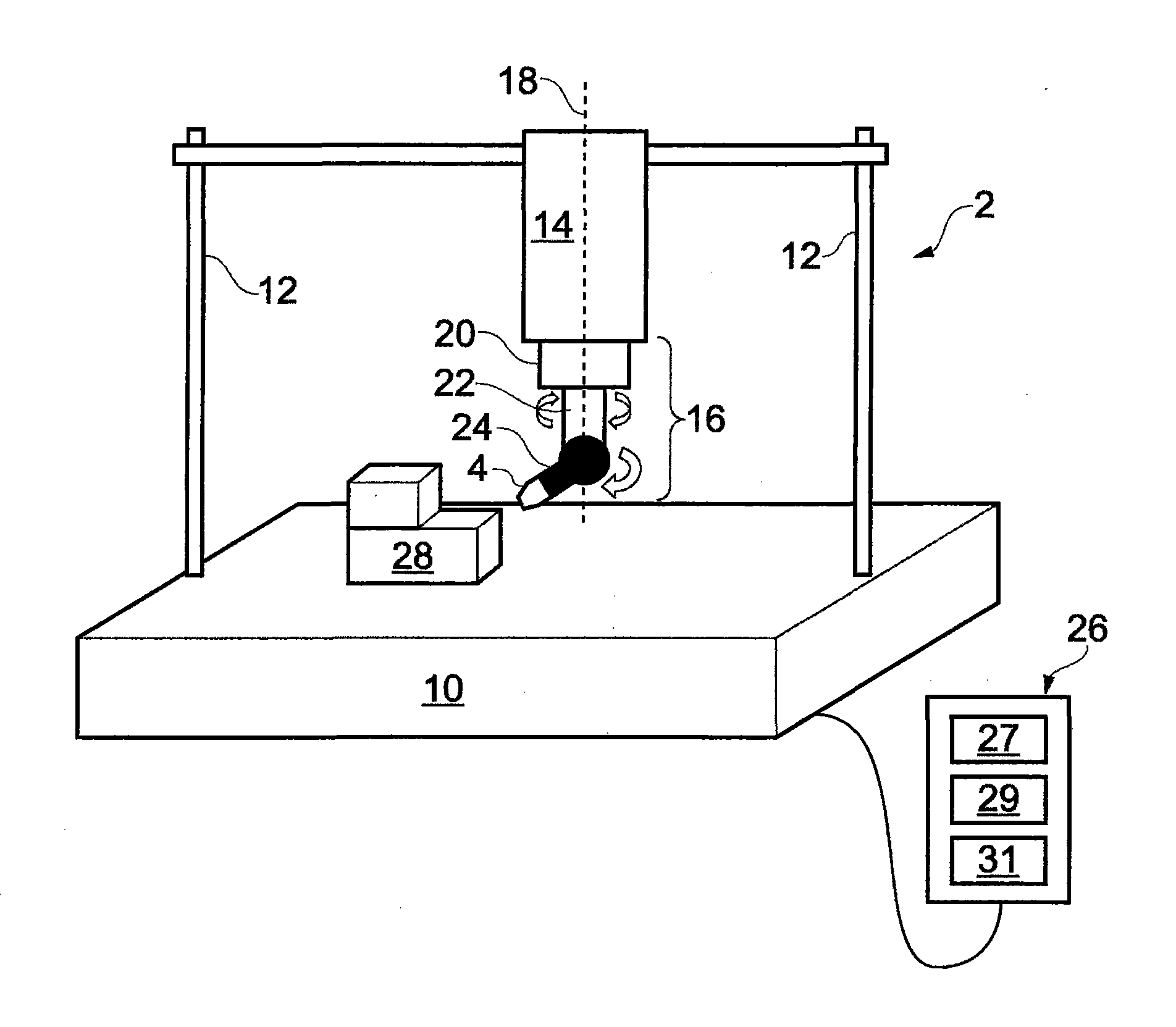

[0087] The CMM 2 includes a base 10 for supporting a frame 12 which in turn holds a spindle 14 . Motors (not shown) are arranged to move the spindle 14 along three mutually orthogonal axes X, Y and Z. The spindle 14 holds an articulation head 16 . The articulating head 16 has a base portion 20 attached to the main shaft 14 , a middle portion 22 and a probe holding portion 24 . The base portion 20 includes a first motor (not shown) for rotating the intermediate portion 22 about the first axis of rotation 18 . Intermediate portion 22 includes a second motor (not shown) for rotating probe holding portion 24 about a second axis of rotation that is substantially perpendicular to the first axis of rotation. Although not shown, bearings may be provided between movable parts of the joint 16 . Additionally, although not shown, measuring encoders may be provided to measure the relative positions of the base 10 , frame 12 , spindle 14 and articulation head 16 so that the position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com