Contact lens visual eye pressure sensor based on strain sensing mechanism and preparation thereof

A contact lens and strain sensing technology, applied in tonometers and other directions, can solve the problems of large elastic modulus, unstable signal, and difficulties of copper foil, and achieve the effect of small elastic modulus and improved sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

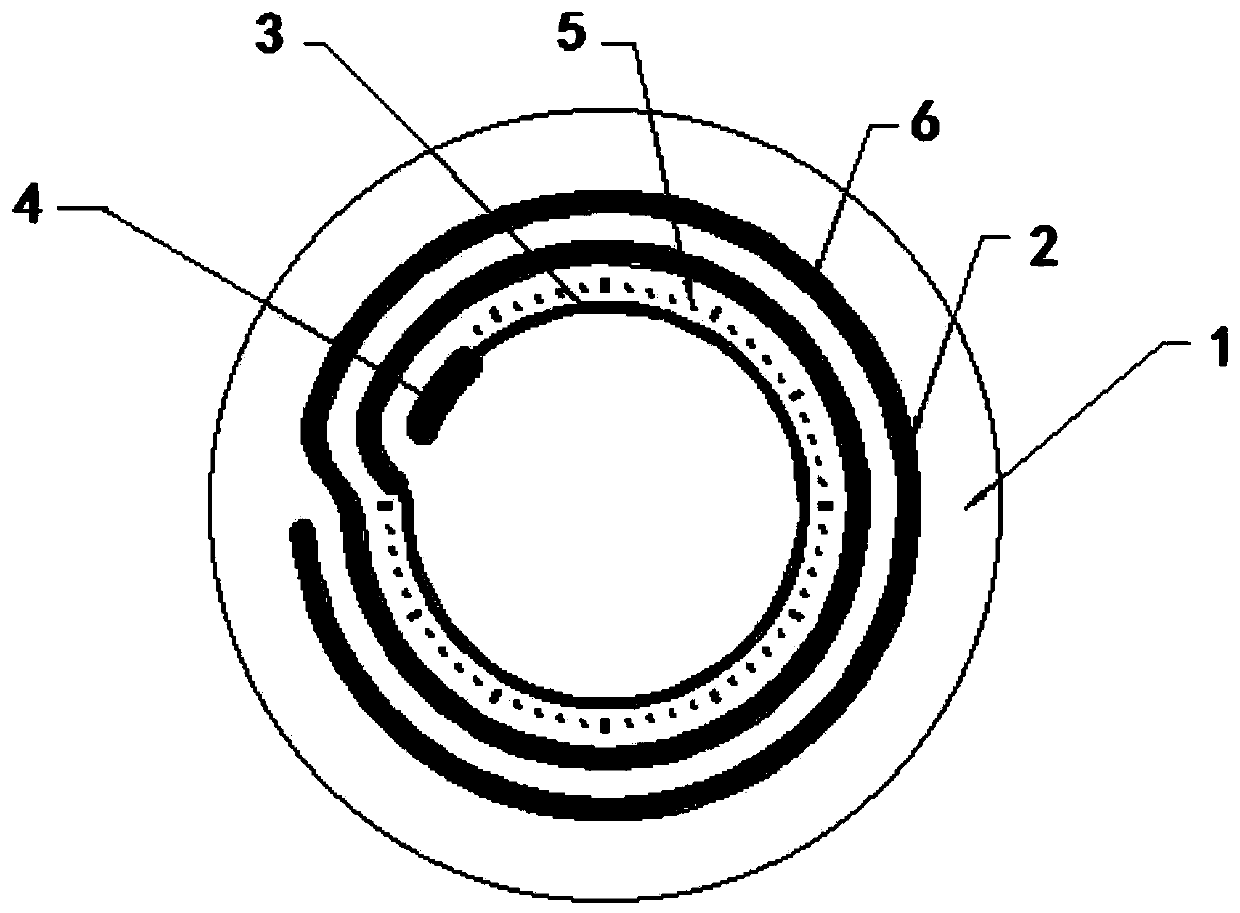

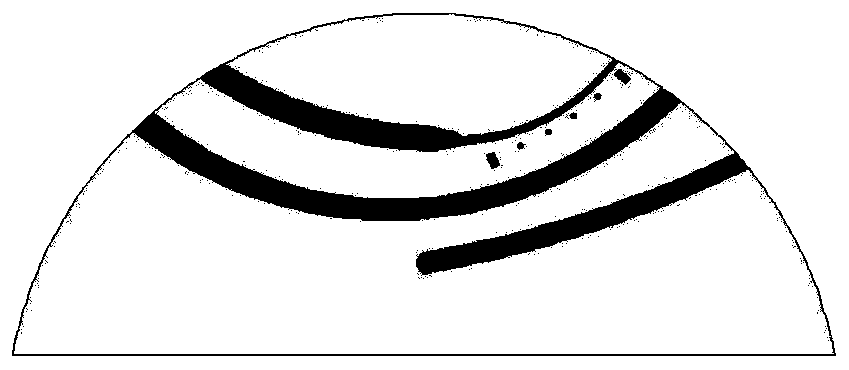

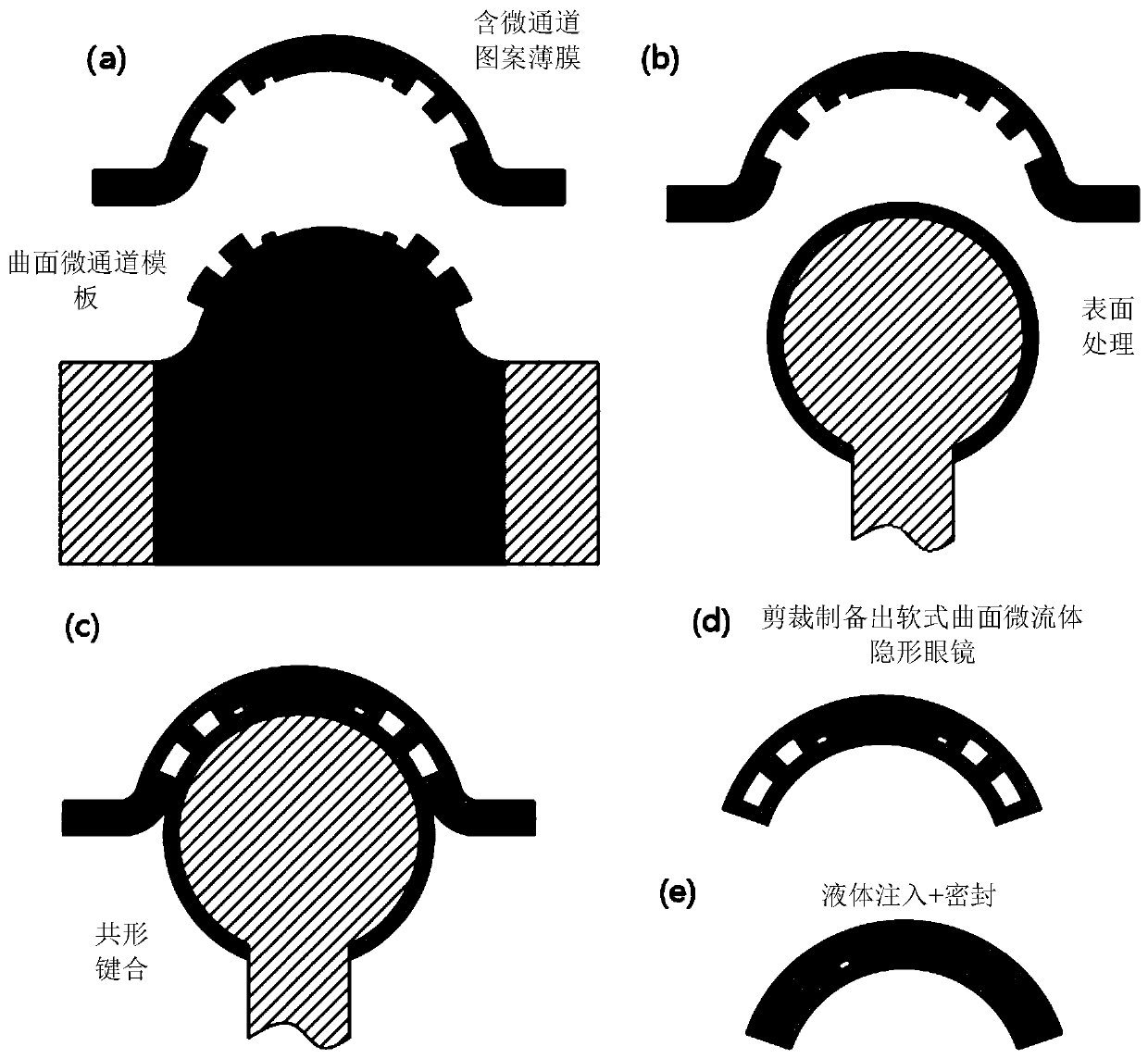

[0032] figure 1 It is a front view showing the structure of the visual wireless contact lens intraocular pressure sensor based on the strain sensing mechanism of the present invention, figure 2 is a side view of the structure of the strain-sensing intraocular pressure monitoring sensor according to the present invention, image 3 (a), (b), (c), (d), and (e) are flow charts of the preparation of the strain-sensing intraocular pressure monitoring sensor according to the present invention using a conformal bonding process. Such as figure 1 As shown in , the strain sensing mechanism intraocular pressure monitoring sensor mainly includes a soft contact lens 1, a microcavity 2 filled with a dyed functional liquid 6, a sensing channel 3, an air chamber 4 and a scale 5, and through the micro The structure of the cavity and the design of its setting method can measure the fluctuation state of intraocular pressure with high precision. The structure of the sensor is simple and conveni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com