Method for eliminating method of inner cavity of shaft type heavy forged piece

A technology for large forgings and shafts, which is applied in the field of modification processing of metal materials, can solve the problems of reduced material strength and increased material cost, and achieve the goal of eliminating internal cavities, avoiding the reduction of material strength, and reducing the cross-sectional area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

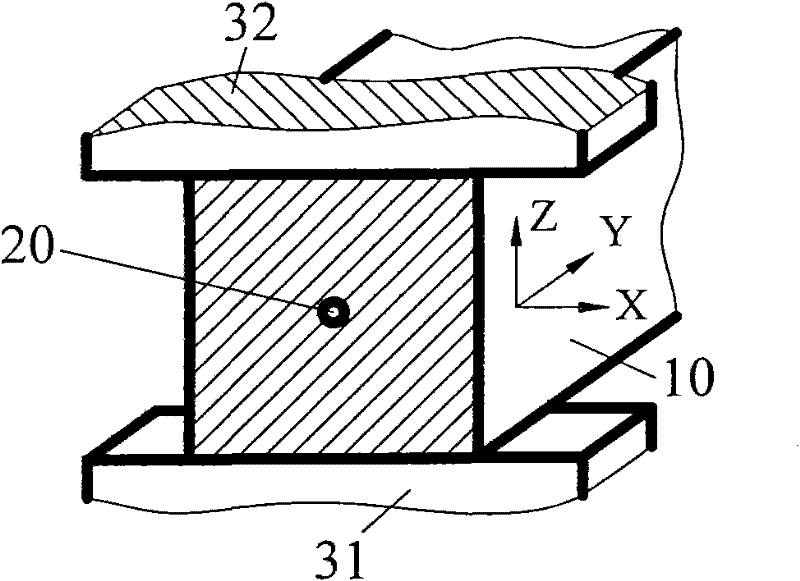

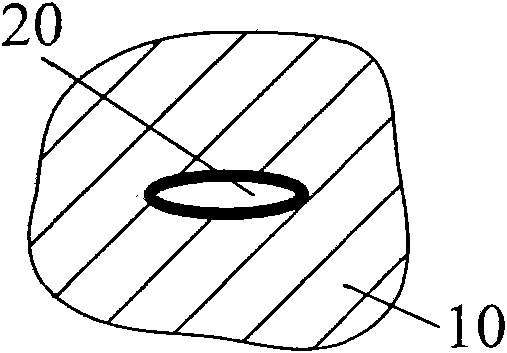

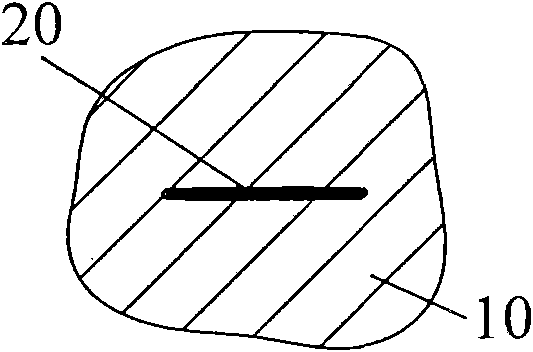

[0032] The large shaft forgings are carbon steel 08 steel with low carbon content (carbon content: 0.05-0.11wt%). Such as figure 1 As shown, the shaft-type large forging is a cuboid steel ingot 10 with a cross-sectional size of 500mm×500mm. It is found by radiographic inspection that there is a cavity 20 with a maximum diameter of 2.0mm near the center. Forging and controlling the amount of unidirectional compression deformation The method removes holes. The material of the lower anvil 31 and the last anvil 32 is designed to be H13, the anvil X direction (left and right direction) dimension L=800mm, and the Y direction (front and rear direction) dimension B=300mm. In the left-right direction (X-axis direction) of the cross-section of the large shaft-type forging, the dimensions of the lower anvil 31 and the upper anvil 32 should be at least 50% larger than the cross-section of the large shaft-type forging.

[0033] Check the forging manual to determine that the initial forgi...

Embodiment 2

[0040]In this example, the steel ingot material of the large shaft forging is changed to carbon steel 35 steel with a middle carbon content (carbon content: 0.32-0.39%); first heat the steel ingot to 1250°C in a heating furnace according to the data in the manual, and keep it warm for 35 minutes. The steel ingot was forged according to the operation process of Example 1. After testing, when the unidirectional compression deformation reached 28.5%, the radiographic flaw detection showed that the cavities had completely bonded to each other.

Embodiment 3

[0042] In this example, the steel ingot material of the large shaft forging is changed to carbon steel 60 steel with higher carbon content (carbon content: 0.57-0.65%), and the steel ingot is first heated to 1200°C in the heating furnace according to the data in the manual, and kept for 30 minutes According to the operation process of Example 1, the steel ingot was forged. After testing, when the unidirectional compression deformation reached 30.6%, the radiographic flaw detection showed that the cavities had completely bonded to each other.

[0043] In the above examples, the heating temperature and holding time can be determined by consulting the forging manual; and the required compression amount does not change much with the replacement of the carbon steel material grade, only because low carbon steel is compared with high carbon steel. , the strength is low, the plasticity is good, and the amount of compression deformation required to eliminate the cavity is small, while t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com