Tungsten copper alloy and its processing method and application

A technology of tungsten-copper alloy and processing method, which is applied in the field of alloy materials, can solve the problems of alloy thermal conductivity, reduced electrical conductivity, and low alloy sintering ability, and achieve the effects of increasing density, improving sintering performance, and good sintering ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] In order to save space, the formulation components of each embodiment and comparative example are listed in Table 1.

[0056] Table 1 embodiment and comparative example formula table

[0057]

[0058]

[0059] It can be seen from Table 1 that the W-Cu-Ag alloy with higher sintered density and performance can be obtained at the same sintering temperature by adding an appropriate amount of Ag.

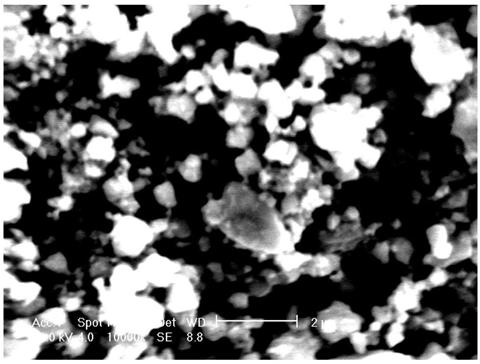

[0060] from figure 1 It can be seen that the calcined silver-containing copper tungstate powder is easy to form large solids due to high temperature. In order to obtain materials that are convenient for further processing, it is necessary to reduce its particle size through ball milling.

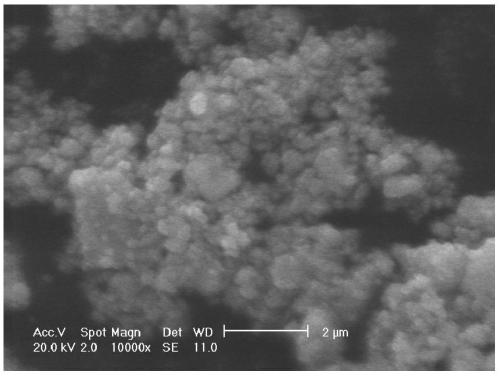

[0061] from figure 2 It can be seen that the particle size of the powder can reach the submicron level after ball milling at a ball-to-material ratio of 3:1 (mass) and a rotational speed of 700RPM for 3 hours. Because the powder is a compound, it is brittle and can be ball milled to a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com