Compact spinning method

A compact and yarn guide technology, applied in the field of bundled fibers and compact spinning methods, can solve the problems of many mechanical moving parts, high maintenance costs and management requirements, and complex devices, and achieve easy maintenance, meet quality requirements, and maintain costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 2

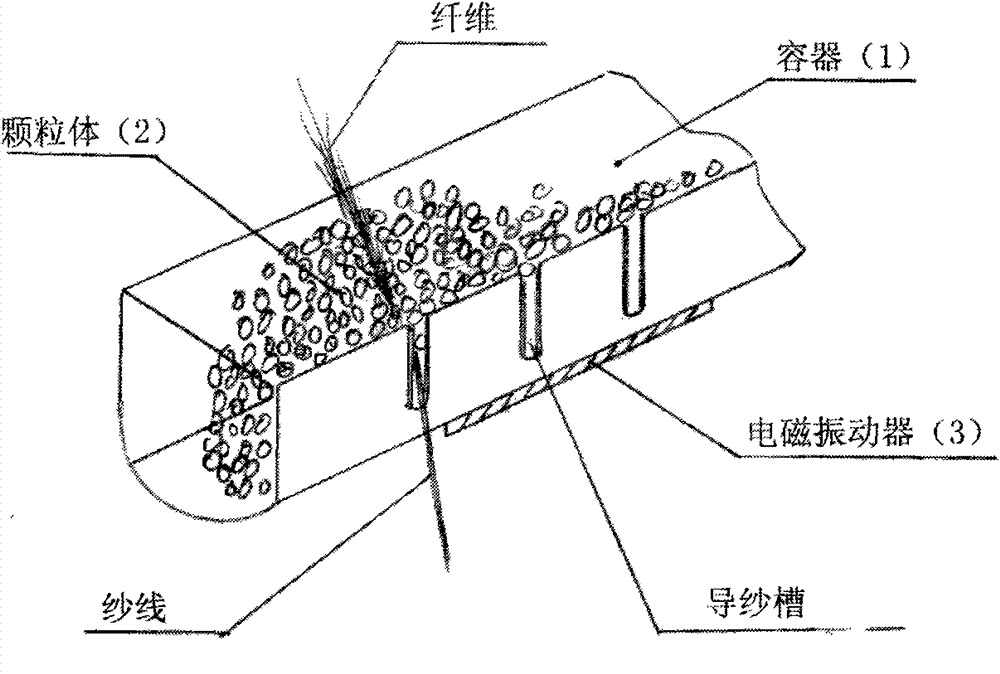

[0032] As attached to the manual figure 2 As shown, the described fiber bundling method of compact spinning has a device structure consisting of a container (1), a granular body (2), and an electromagnetic vibrator (3).

[0033] The container can be made of metal or non-metal, and is used to hold small particles. The container is elongated and segmented, and yarn guide notches are arranged at intervals, which are yarn guides.

[0034] The particles are small metal and non-metal particles with no fixed shape or a mixture of metal and non-metal. The small particle group is subjected to vibration at a certain frequency in the container, and the particles are continuously extruded, arranged and combined. It acts on the passing fibers and plays the role of bundled fibers.

[0035] The vibrator (3) is composed of the principle of an electromagnetic vibrator, assembled at the bottom of the container, and generates transverse or longitudinal vibration with a certain frequency, inten...

specific Embodiment 3

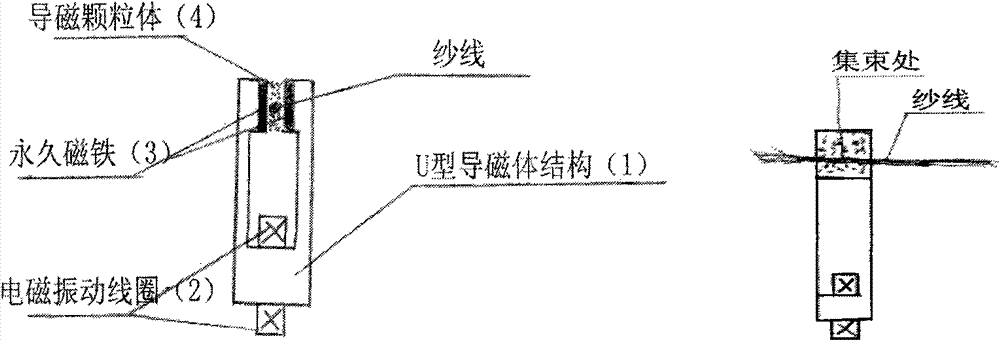

[0037] The following is attached with the manual image 3 describe in detail

[0038] As attached to the manual image 3 As shown, a fiber bundling method for compact spinning, the device structure can be composed of a U-shaped magnetic conductor structure (1), an electromagnetic oscillating coil (2), a permanent magnet (3), and magnetic permeable particles (4).

[0039] In the U-shaped magnetic body structure (1), when there is an AC magnetic field, the two sides of the U-shape can produce a change in the amplitude of the density gap at a certain frequency.

[0040] The electromagnetic coil (2) can generate an alternating magnetic field magnetic force of a certain conductor after electrification.

[0041] The permanent magnet (3) is made of commonly used common permanent magnetic material, adheres to both sides of the upper end of the U-shaped body, and plays the role of absorbing magnetically conductive particles.

[0042] The magnetically conductive particles (4) are com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com