Magnetic fluid controller for fluid control of boundary layer of moving object

A fluid controller and boundary layer technology, applied in the direction of fluid flow, mechanical equipment, etc., can solve the problems of electrode surface corrosion, affecting electrode service life, low control efficiency, etc., to reduce corrosion, prolong service life, and expand control range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings.

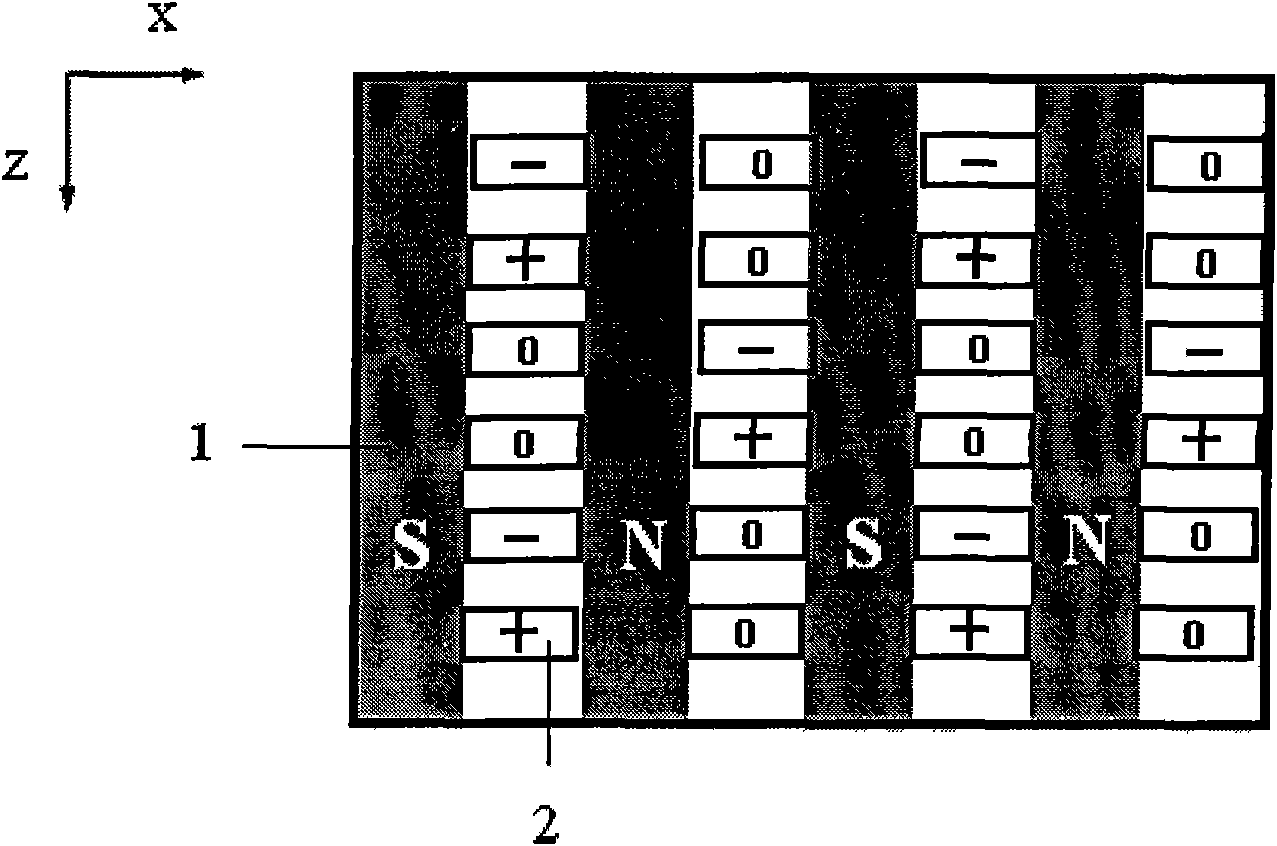

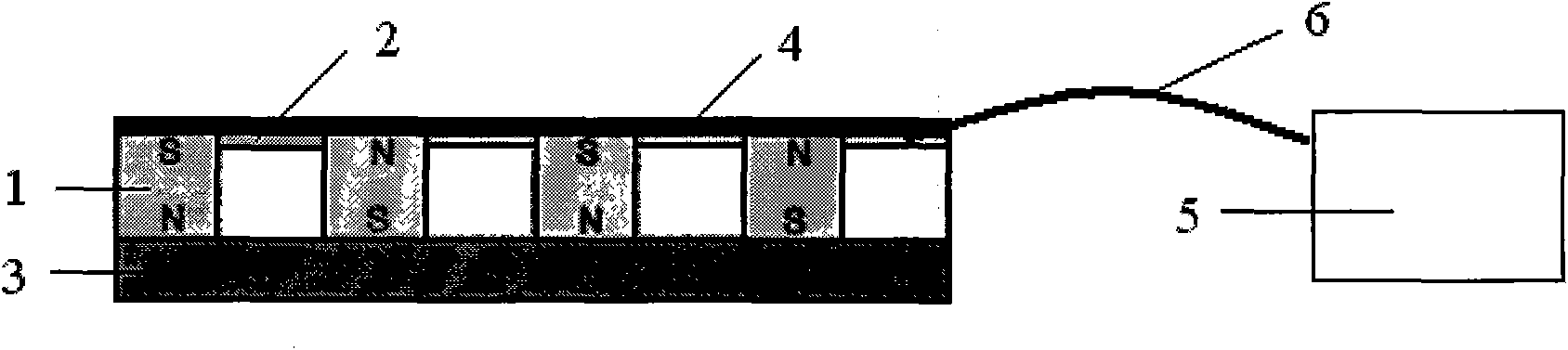

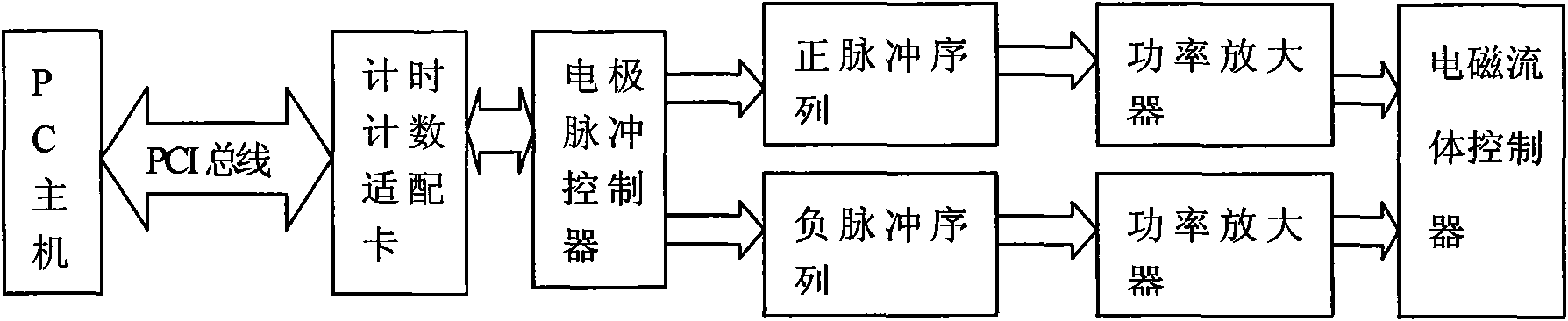

[0013] Combine figure 1 , figure 2 The present invention discloses an electromagnetic fluid controller for controlling the boundary layer fluid of a moving body. It includes a magnetic pole 1, an electrode, a base 3 and a cover plate 4. The magnetic pole 1 and the electrode are arranged in the base 3 and the cover plate in a horizontal direction. 4, the polarities of the two adjacent magnetic poles are opposite. Each electrode is connected to the electrode pulse controller 5 through a wire 6. The electrode is composed of a number of small electrodes 2 arranged between two adjacent magnetic poles and distributed in a matrix on the base 3. The distance between the small electrodes 2 in the same column and the cover plate 4 can be 0.6 to 1.5 times its width, and each small electrode 2 is connected to the electrode pulse controller 5 through a wire 6 respectively.

...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap