Device for on-line monitoring residue calendar life of high-temperature pressure-containing member outside furnace and method thereof

A technology of pressure-bearing components and monitoring devices, which is applied in program control, control system, computer control, etc., can solve the problems of uneven temperature distribution, large thermal stress, and shortening the remaining calendar life of high-temperature pressure-bearing components outside the boiler of power station.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

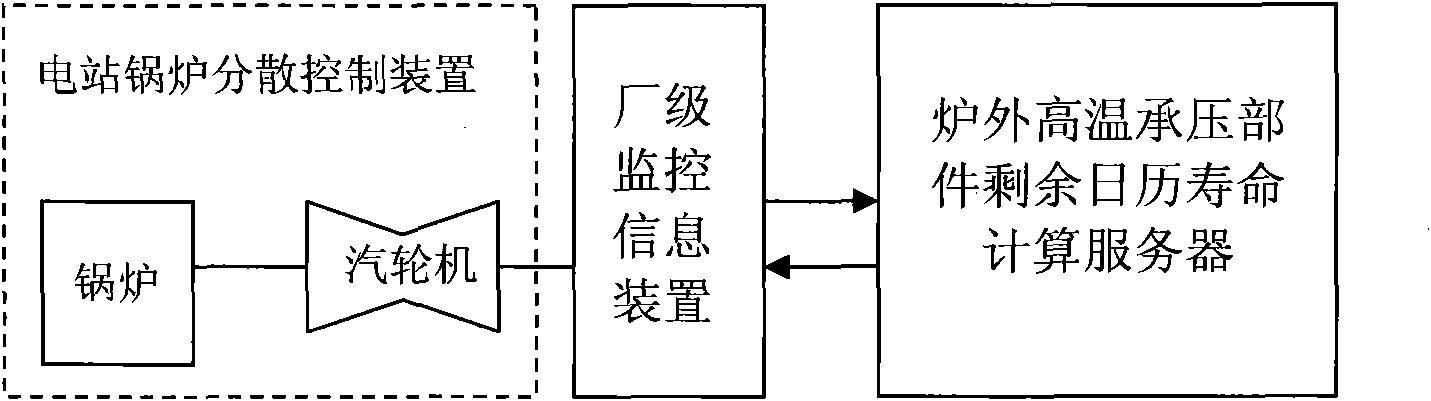

[0074] Such as figure 1 Shown is a block diagram of the on-line monitoring device used in the present invention. The on-line monitoring device for the remaining calendar life of the high-temperature pressure-bearing parts outside the furnace of the power plant boiler of the present invention uses the remaining calendar life calculation server and factory-level monitoring information of the high-temperature pressure-bearing parts outside the furnace. device and power plant boiler distributed control device. The remaining calendar life calculation server of the high-temperature pressure-bearing parts outside the furnace is connected to the distributed control device of the power plant boiler through the plant-level monitoring information device.

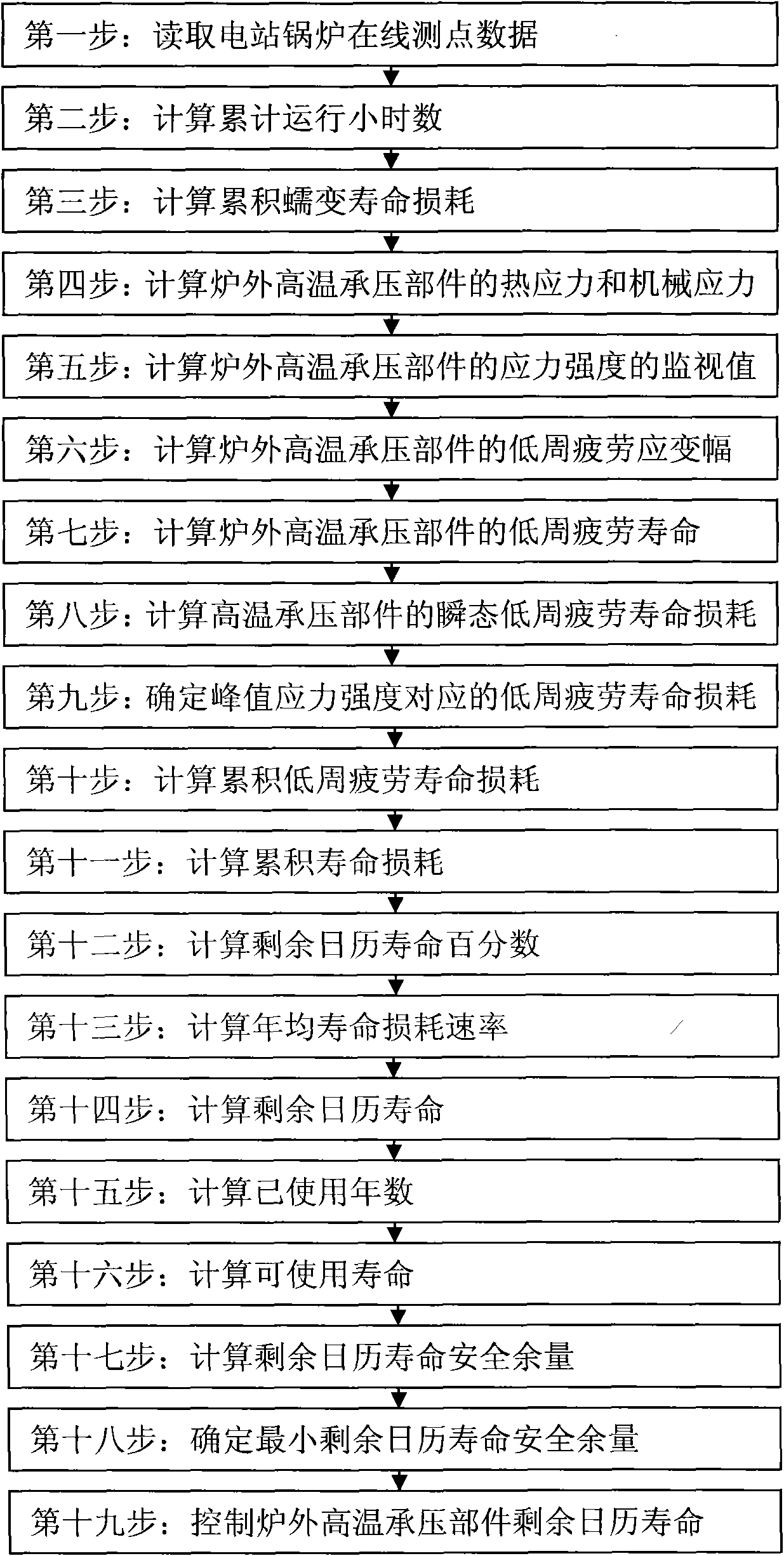

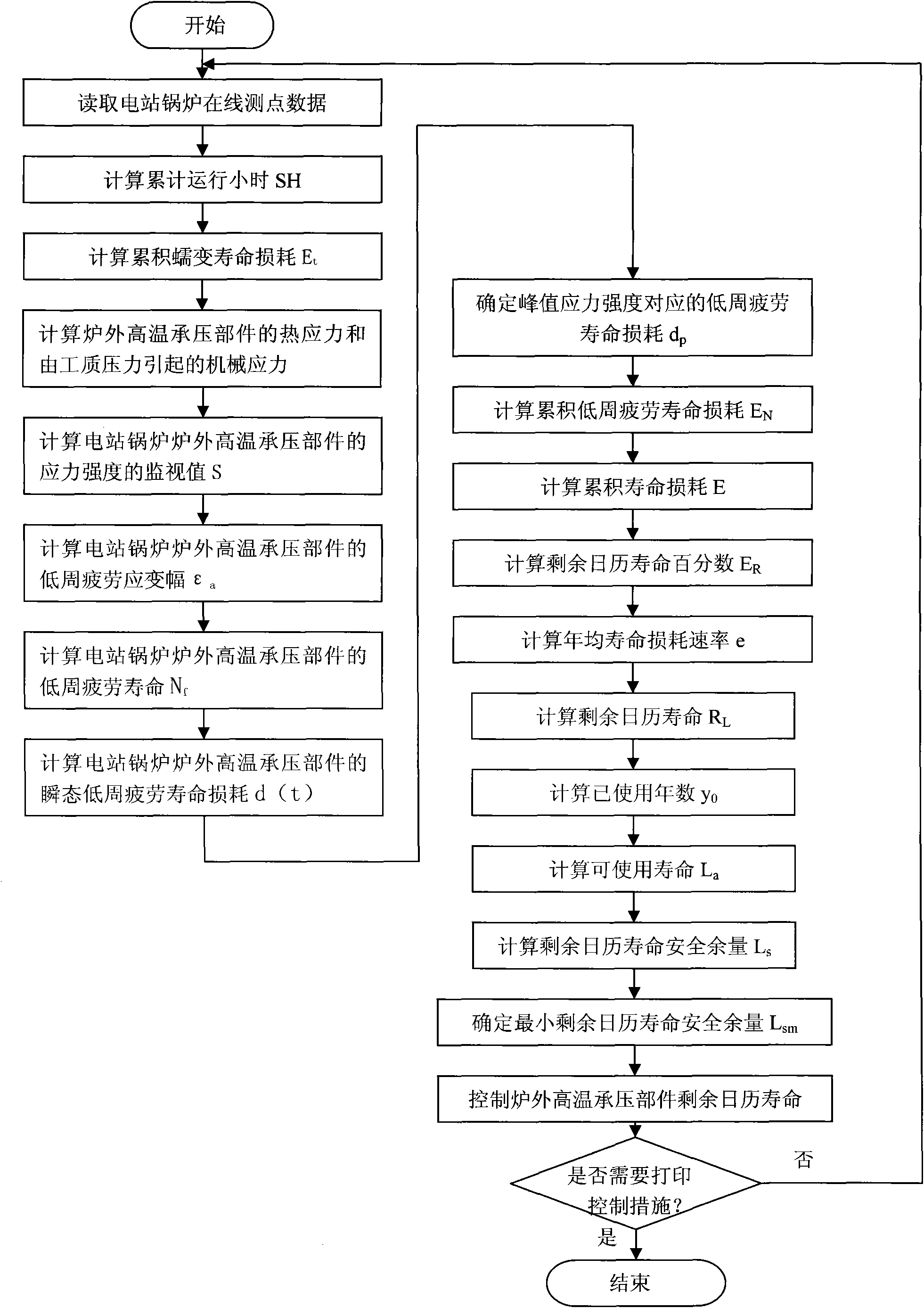

[0075] Such as figure 2 Shown, is the flowchart of the method adopted in the present invention, as image 3 As shown, it is a block diagram of the computer software used by the calculation server. The software is installed on the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com