Coal supply method of optimizing fire power plant by real-time coal firing heat value coefficient

A technology of coal-fired calorific value and coefficient, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as large differences in heat, no practical value, and no published patent documents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The specific embodiments of the present invention will be further detailed below in conjunction with the drawings

[0025] A method for optimizing coal supply for thermal power plants using real-time coal-fired calorific value coefficients, the specific steps are as follows:

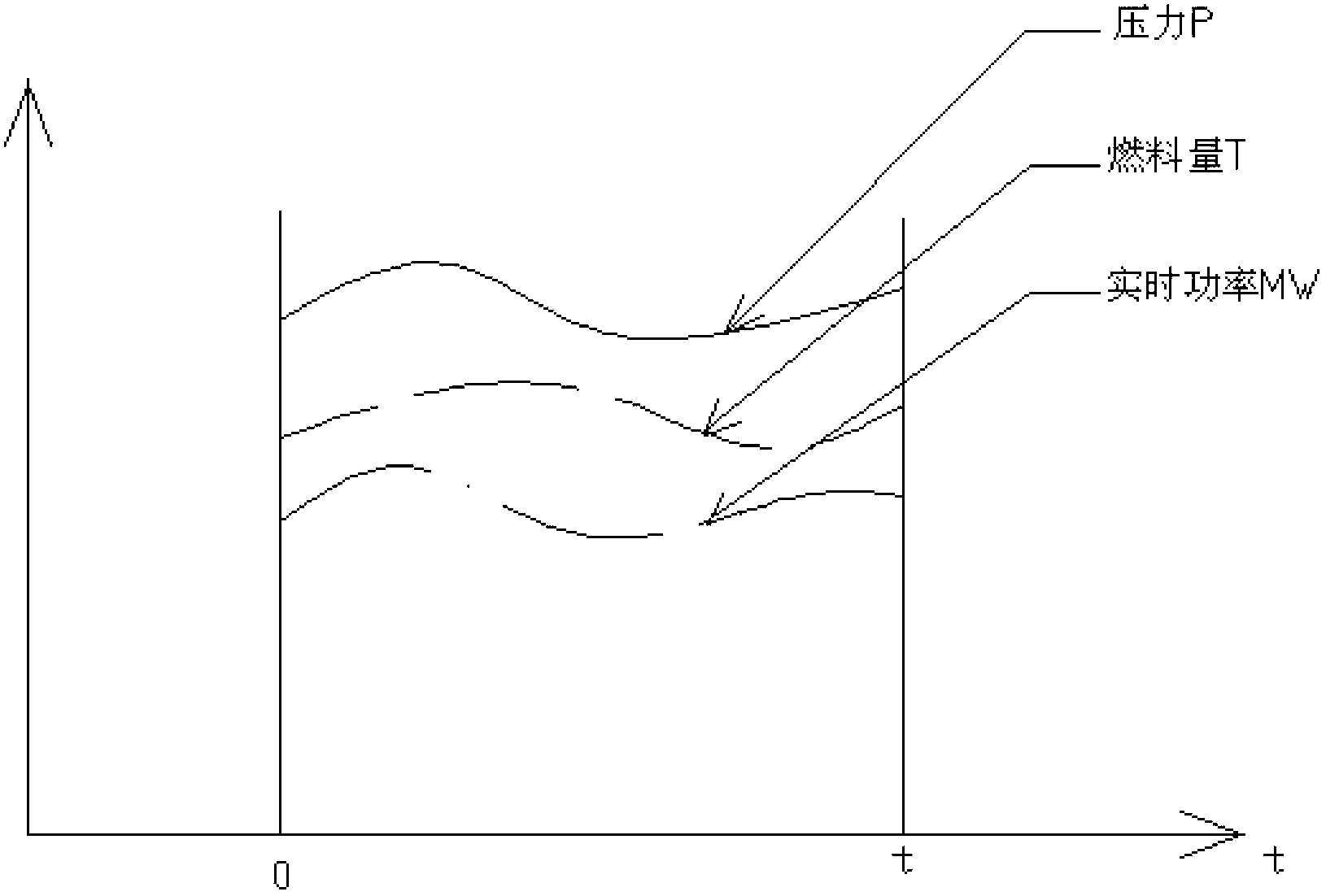

[0026] ⑴Determine the time interval: when the generator set is stable, take a certain moment as the starting point of timing 0, take the time t as the end of timing, and determine the time period t as the time period for calculating the comprehensive coefficient of coal heating value;

[0027] ⑵Continuously record variable values in time period t: Record three variables of power MW, fuel quantity T, and drum pressure P of the generator set in real time after stable operation, and draw the variable curve in time period t;

[0028] ⑶ Derive the fuel quantity per unit power in the time period t: first add up the real-time power MW of the generator set, the fuel quantity T, and the total amount in the time p...

Embodiment 2

[0038] In this embodiment, the conversion constant C between pressure and coal quality is calculated; C=(C 0 -P t ) / (C 0 -P 0 ), where P 0 , P t The pressure value of can be replaced by the main steam pressure value for the generator set drum pressure value. Because the change of main steam pressure is similar to that of generator set drum pressure, the difference between the two calculations can be ignored.

[0039] Therefore, the pressure correction constant C in this embodiment 0 The test can also be obtained through the main steam pressure value instead of the generator set drum pressure value:

[0040] ⑴ The initial conditions of the measurement test are: the power generation load of the generator set is 250MW, the main steam pressure is 16MPa, the operating fuel quantity of the generator set is 125 tons / hour, and the coal quality remains unchanged during the test;

[0041] (2) The termination conditions of the measurement test are: the power generation load of the generator set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com