Detector element matrix for an optical position measuring device

A technology for detecting components and measuring devices, applied in measuring devices, converting sensor output, instruments, etc., can solve problems such as low pixel density, achieve high pixel density, good signal quality, and reduce connection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

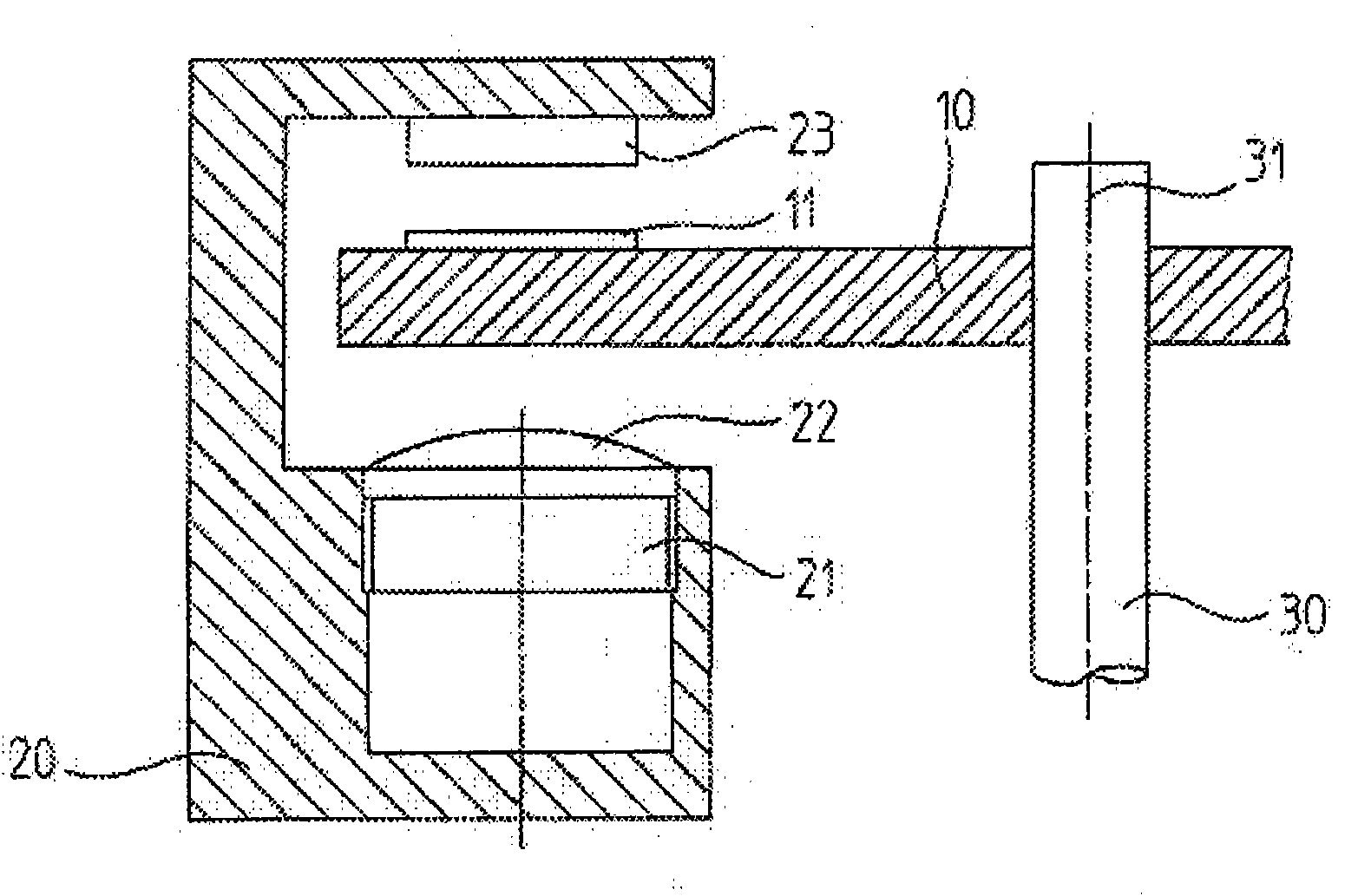

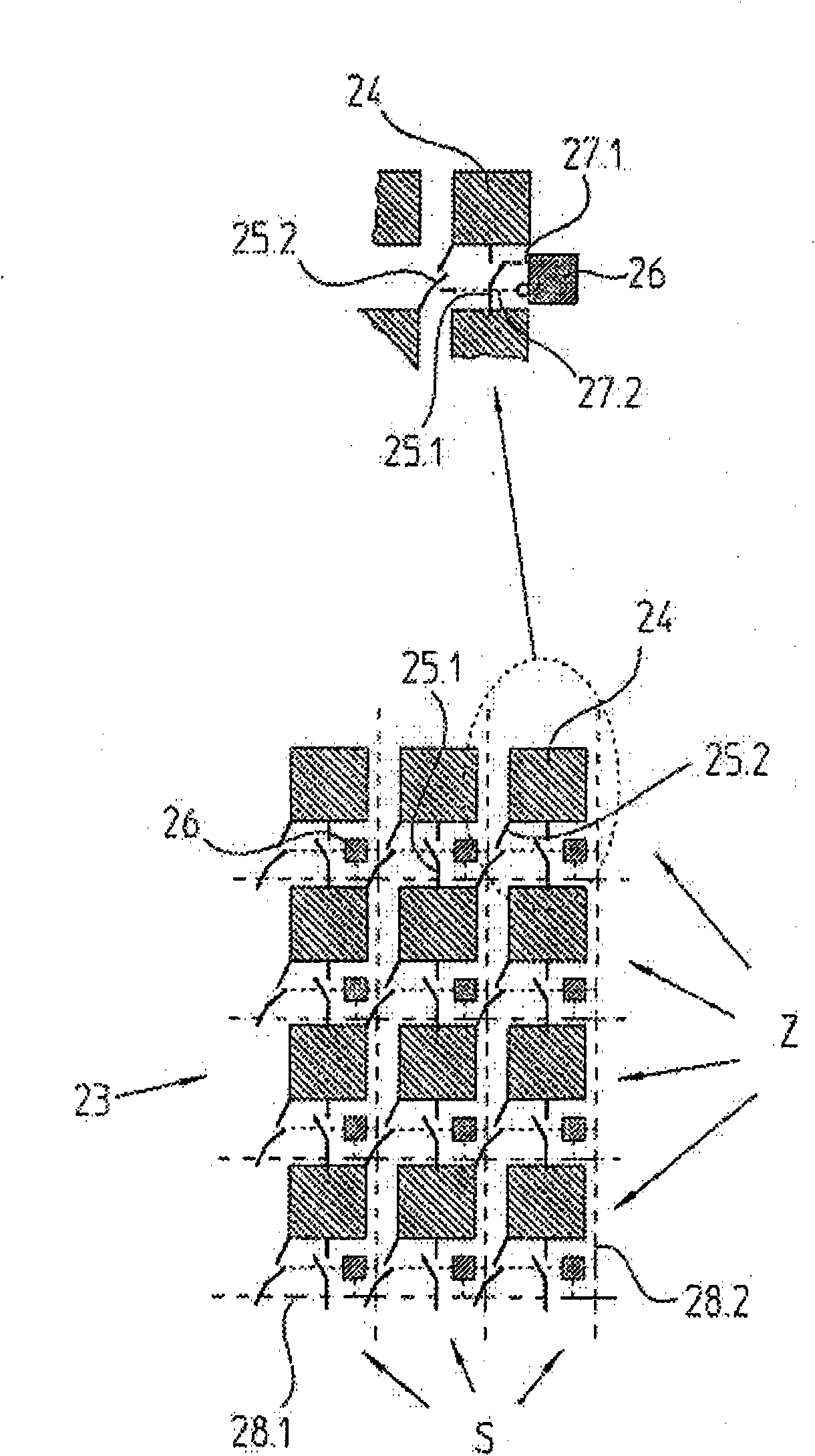

[0044] exist figure 1In a very simplified illustration, a rotating optical position measuring device is shown, which is formed by an array 23 of detection elements according to the invention. The position-measuring device is used to generate position information and the relative movement of a body rotating about an axis 31 , which is not shown in the drawing. Such a position-measuring device can be used, for example, in machine tools or electric drives and there provide a superordinated control unit with information about the position of the rotating body.

[0045] Such a position-measuring device comprises, on the one hand, a scale 10 on which an incremental measuring scale 11 is arranged. The measuring scale 11 consists of a track arranged circularly around the axis 31 and has selectable transparent or opaque scale areas, which are each rectangular, the opaque scale areas can be provided with a chrome layer, for example. The dial 10 is arranged centrally on a shaft 30 rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com