Wiper shaft fixing support

A technology for fixing brackets and wiper shafts, which is applied in the field of wiper blades of general automobiles, can solve problems such as difficult failure of axial force, large head reaction force, and head injury, so as to reduce impact force, reduce reaction force, and improve The effect of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

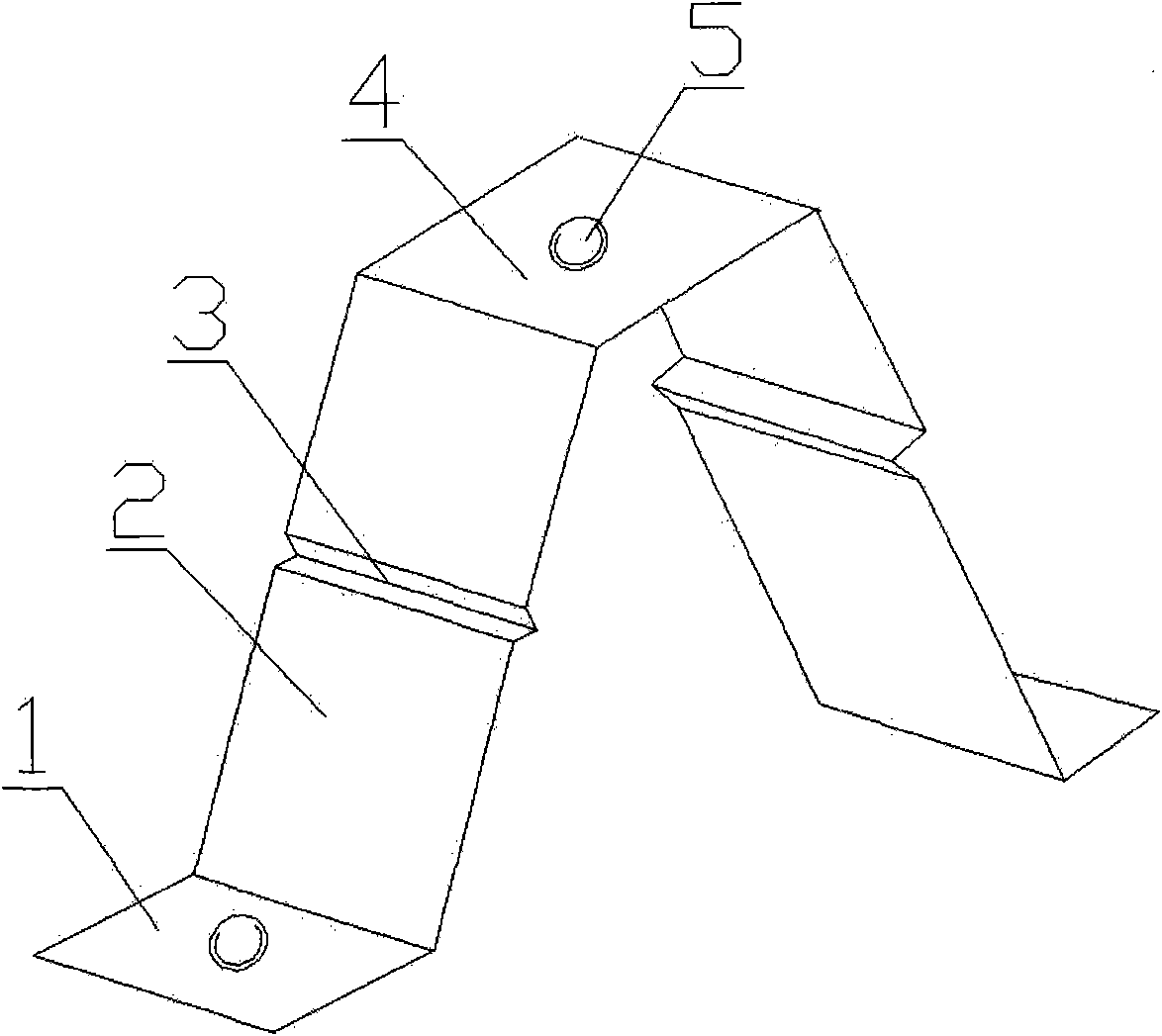

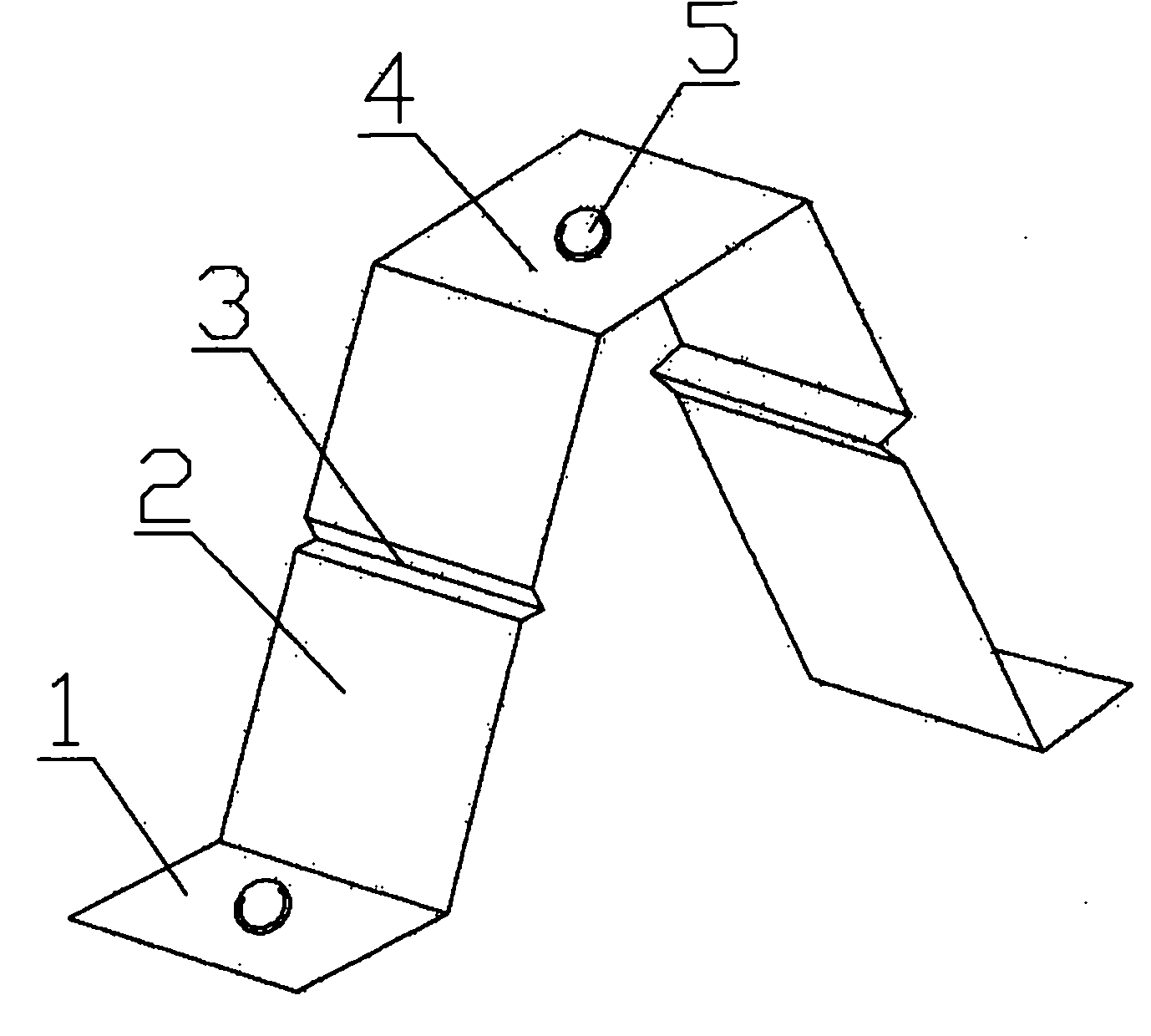

[0025] Such as figure 1 Shown, the technical scheme of the embodiment of the present invention (1) is as follows:

[0026] A wiper shaft fixing bracket, which includes a wiper shaft fixing surface 4 located on the upper layer, supporting surfaces 2 are arranged on both sides of the wiper shaft fixing surface 4, and the lower ends of the supporting surfaces 2 on both sides are respectively connected with bracket fixing surfaces 1, and the lower end of the supporting surface 2 is respectively connected to the inner side of the two bracket fixing surfaces 1; the lateral direction of the supporting surface 2 is provided with an induction groove 3 and the cross section of the induction groove 3 is V-shaped; the bracket fixing surface 1, the supporting surface 2 1. The induction groove 3 and the wiper shaft fixing surface 4 are formed into a "several" shape by stamping; the wiper shaft fixing surface 4 is provided with threaded holes 5; the bracket fixing surface 1 is provided with ...

Embodiment 2

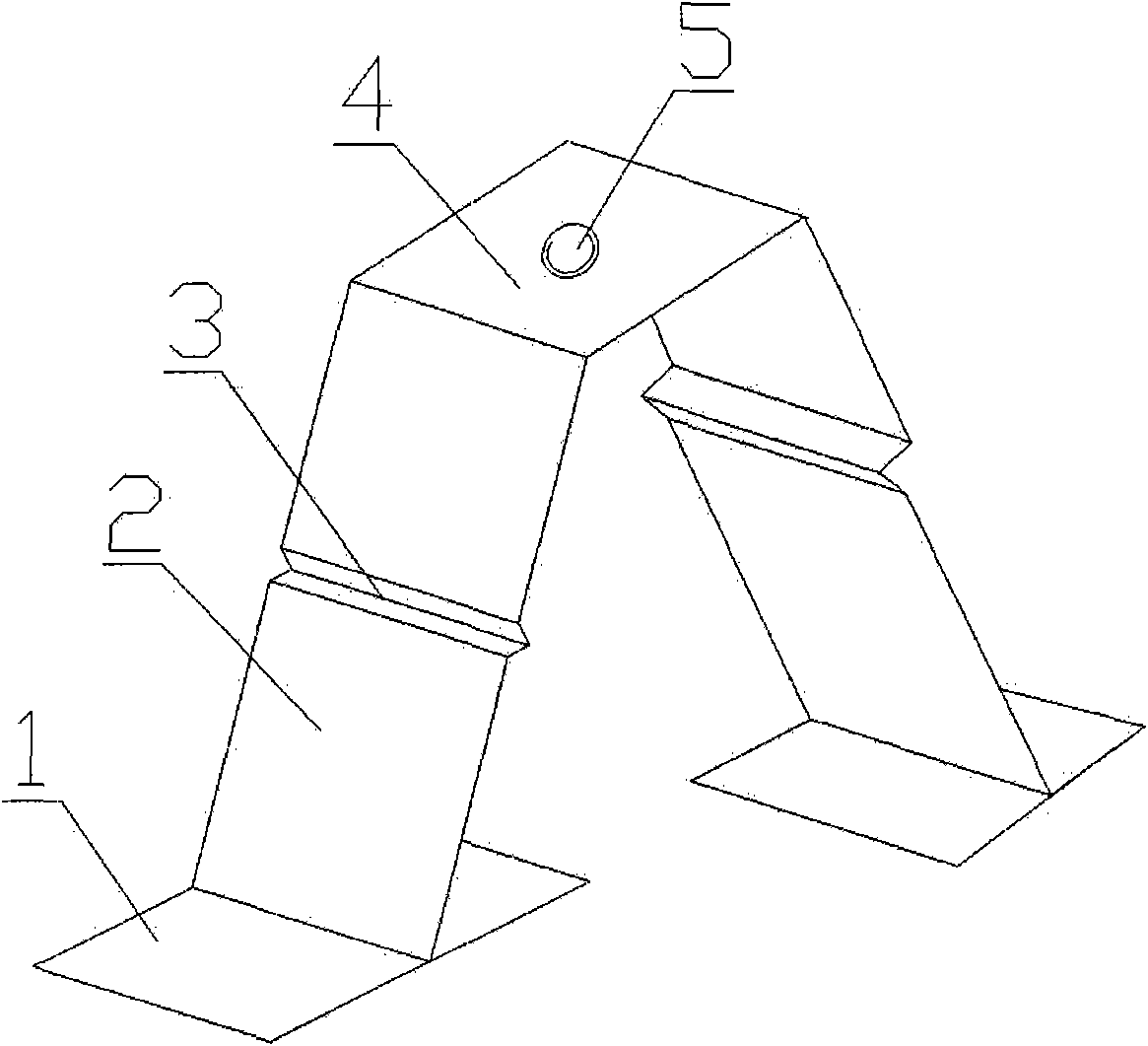

[0035] Such as figure 2 Shown, the technical scheme of the embodiment of the present invention (2) is as follows:

[0036] A wiper shaft fixing bracket, which includes a wiper shaft fixing surface 4 located on the upper layer, supporting surfaces 2 are arranged on both sides of the wiper shaft fixing surface 4, and the lower ends of the supporting surfaces 2 on both sides are respectively connected with bracket fixing surfaces 1, and the lower end of the supporting surface 2 is fixedly connected with the middle of the two bracket fixing surfaces 1 respectively; the supporting surface 2 and the wiper shaft fixing surface 4 are formed as a whole by stamping, and the lower end of the supporting surface 2 is welded to the bracket for fixing On the surface 4; in the transverse direction of the support surface 2, an induction groove 3 is provided, and the cross section of the induction groove 3 is V-shaped; on the wiper shaft fixing surface 4, a threaded hole 5 is provided.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com