Strengthening method for armoured concrete slab

A reinforced concrete slab and anchoring technology, applied in the processing of building materials, building maintenance, construction, etc., can solve the problem of limited function of restoring the original structure performance, complicated structural measures, high-strength steel strands and high bond stress level of polymer mortar. problems, to achieve the effect of improving safety and seismic performance, improving reliability and economy, and improving co-working performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

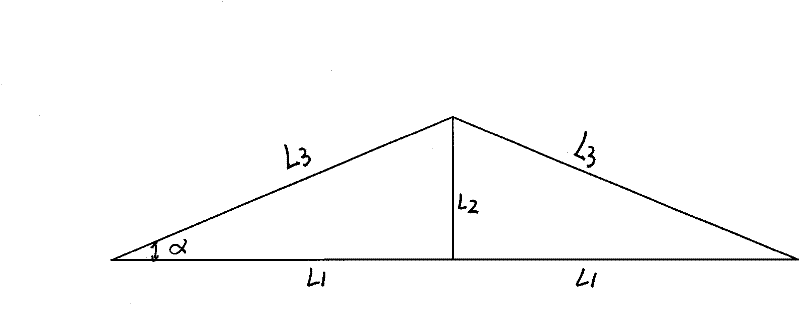

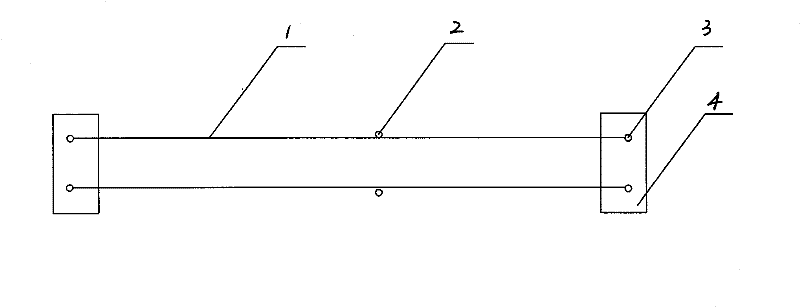

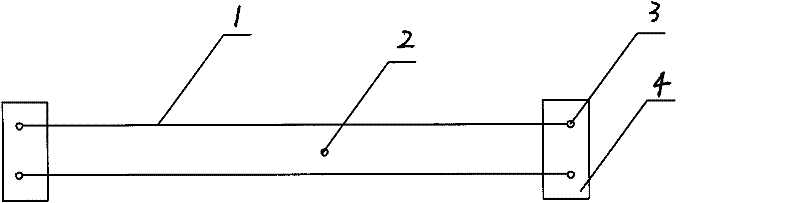

[0034] Embodiment 1, with reference to Figure 2-5 , a reinforcement method for reinforced concrete slabs, which uses a permanent mechanical anchoring device to install the cable material 1 in the tension area of the reinforced concrete slab; after anchoring, the reinforced concrete slab is used as a counter force device to Material 1 is stretched transversely to apply prestress and fixed, and then polymer mortar is applied to cover the entire anchoring device and cable material 1.

Embodiment 2

[0035] Embodiment 2, the reinforcement method of the reinforced concrete slab described in embodiment 1, its concrete steps are as follows:

[0036] (1) Clean the surface of the reinforced concrete slab to expose the concrete structure layer; install anchor bolt groups and steering bolt groups on the reinforced reinforced concrete slab; every 2 groups of anchor bolt groups are used in conjunction with 1 group of steering bolt groups, and the steering bolt groups The group is set in the middle of the 2 groups of anchor bolt groups; in every 2 groups of anchor bolt groups used together with 1 group of steering bolt groups, the reinforcement cable 1 is bypassed from one group of anchor bolt groups to the other group of anchor bolt groups And preliminarily tensioned, then install the anchor plate 4 with adhesive material on the bottom on the anchor bolt group and tighten it, and finally lock the cable material 1 with a lock; each anchor bolt group is provided with at least 2 anchor...

Embodiment 3

[0038] Embodiment 3, the reinforcing method of the reinforced concrete slab described in Embodiment 2, the cable material 1 adopts a continuous winding method during installation, and cuts off after bypassing all the anchor bolts 3 continuously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com