Unidirectional load self-braking spiral braking device

一种螺旋式、制动器的技术,应用在卷扬装置等方向,能够解决发热量大、使用寿命和制动可靠性不是很理想、散热困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

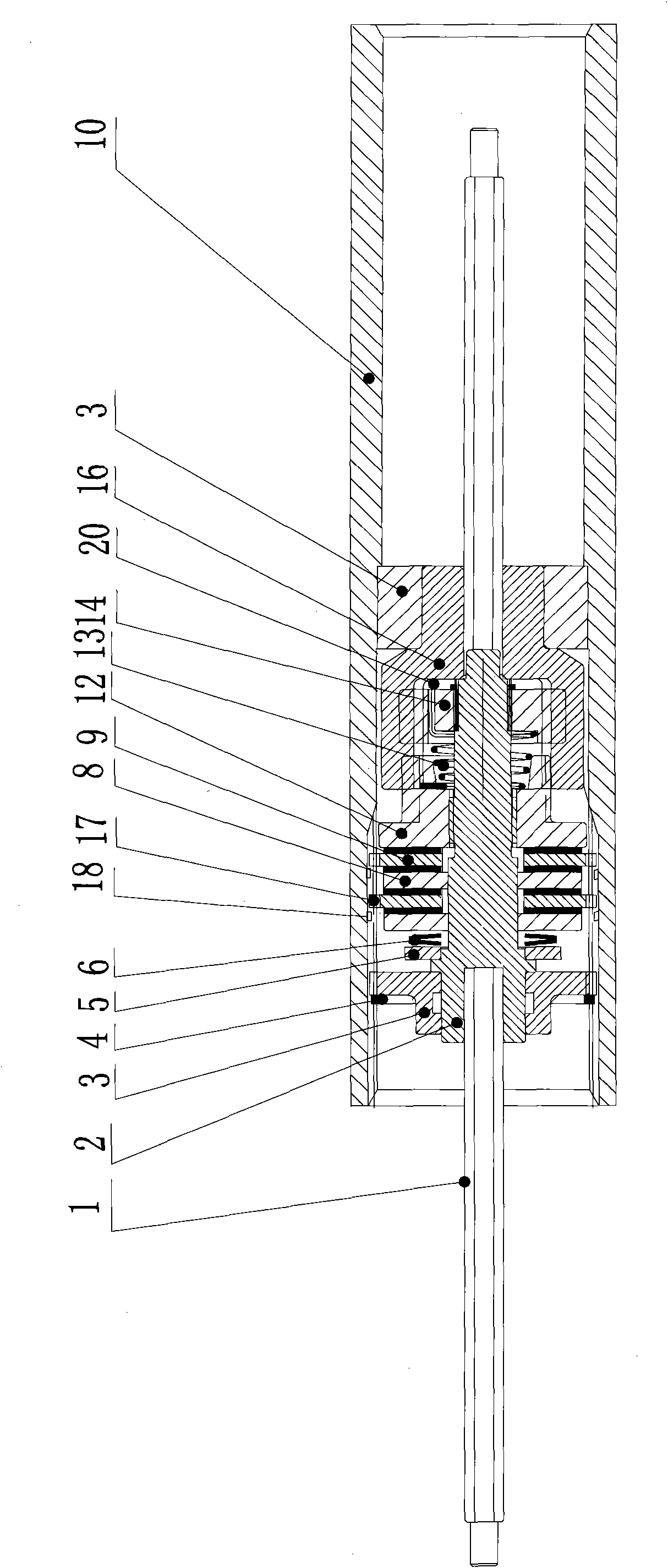

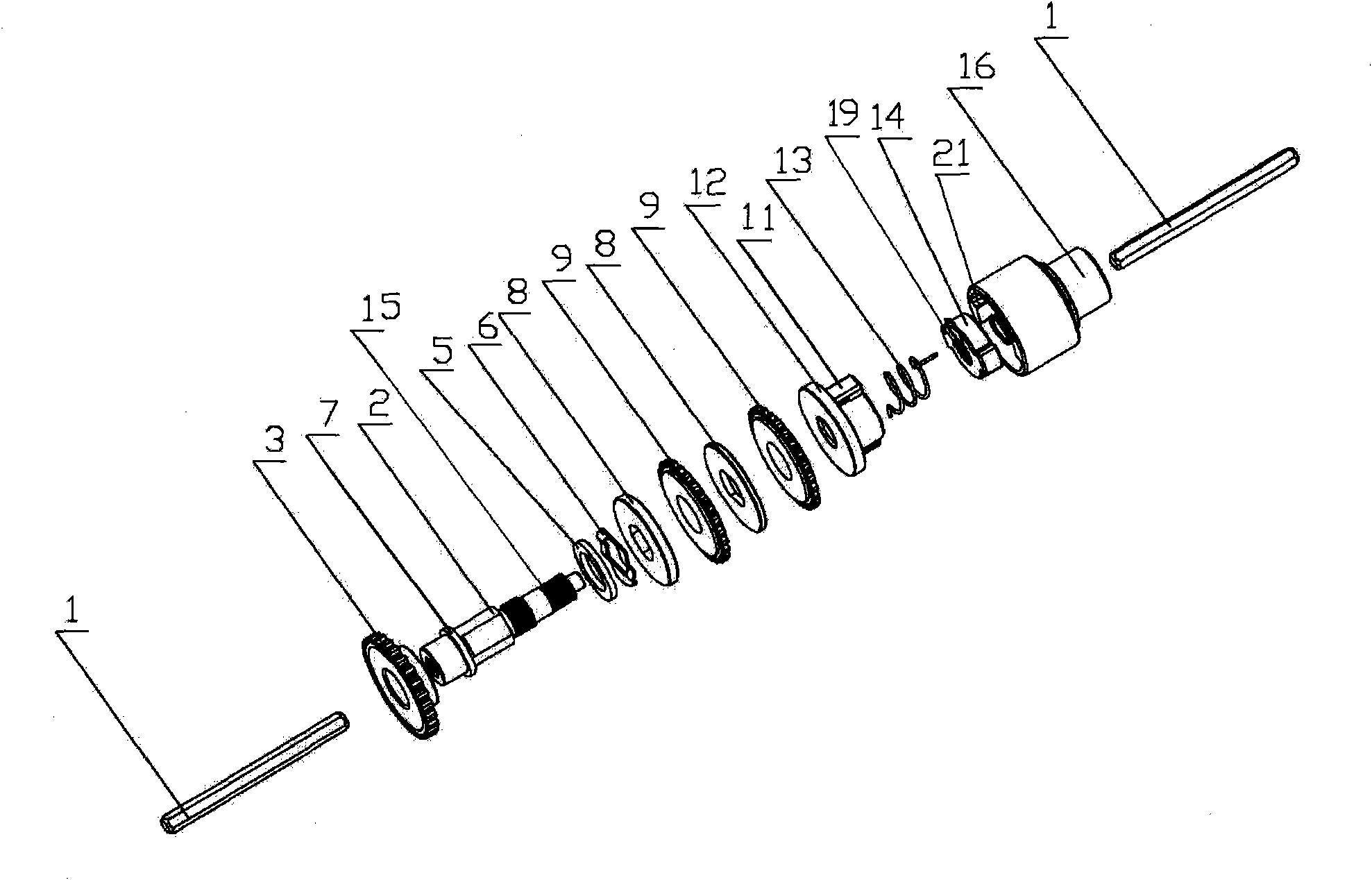

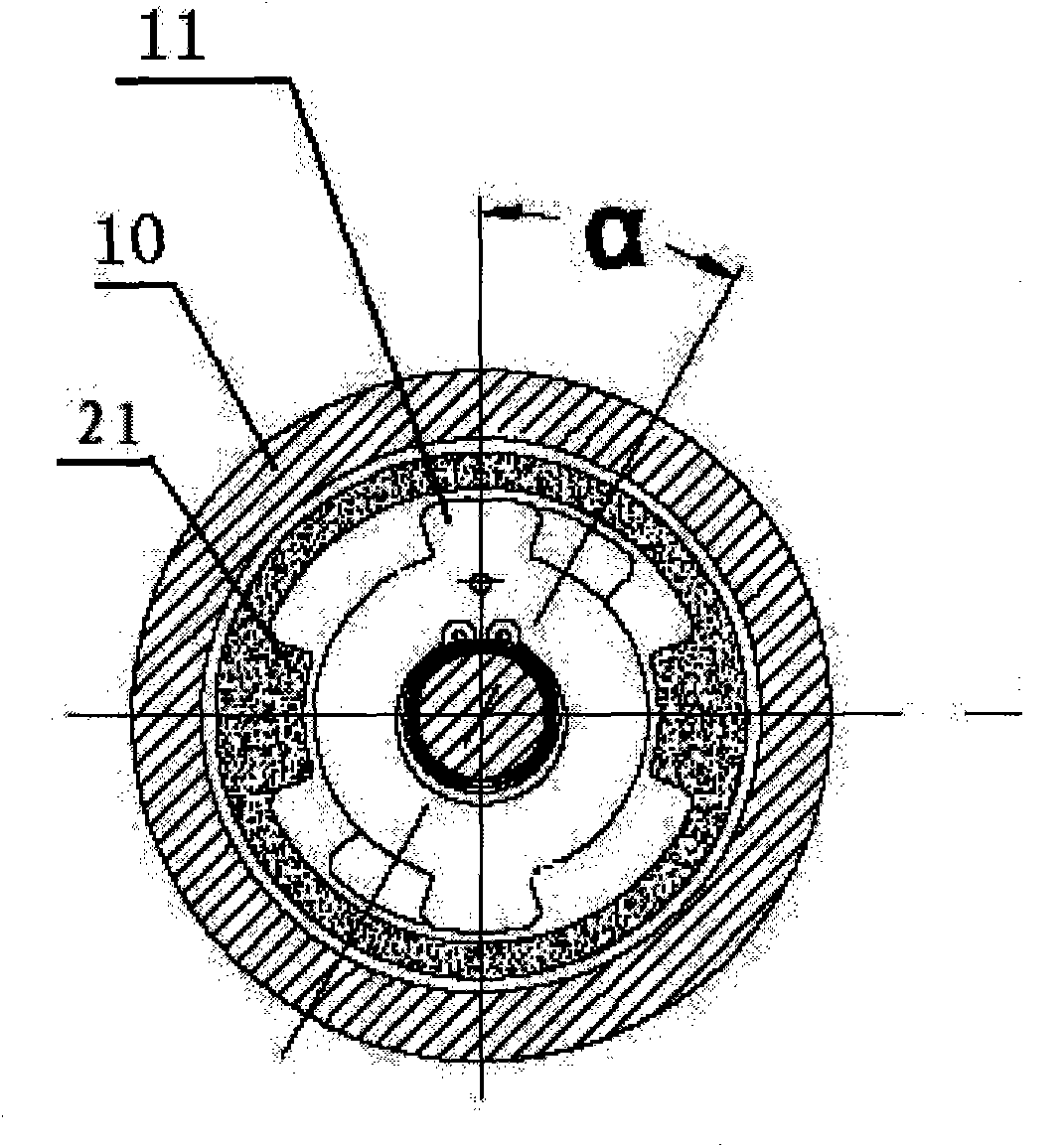

[0018] Such as figure 1 , figure 2 as well as image 3 As shown, a self-made spiral brake with one-way load of the present invention includes a reel 10, two bearing housings 3 are installed in the reel 10, a brake shaft 2 is erected between the two bearing housings 3, and the two ends of the brake shaft 2 are connected There is a transmission shaft 1, and the front end of the brake shaft 2 is provided with a fixing piece 7, starting from the fixing piece 7, the inner friction plate 8 and the outer friction plate 9 which are installed alternately on the brake shaft 2, and the internal thread pressure plate 12, Torsion spring 13, connecting piece 14, brake coupling 16, the inner friction plate 8 meshes with the brake shaft 2, the outer ring of the outer friction plate 9 has external teeth 17, and the front end sleeve of the brake coupling 16 Connected to the outside of the internally threaded pressure plate 12, the torsion spring 13 and the connecting piece 14, the reel 10 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com