Steam station capable of removing calcium scale

A scale and steam technology, applied in the direction of steam generation, steam generation method, boiler cleaning control device, etc., can solve the problems of affecting the heating efficiency, reducing the volume of the boiler 5, occupying the space of the boiler 5, etc., to simplify the operation and improve the use The effect of life, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

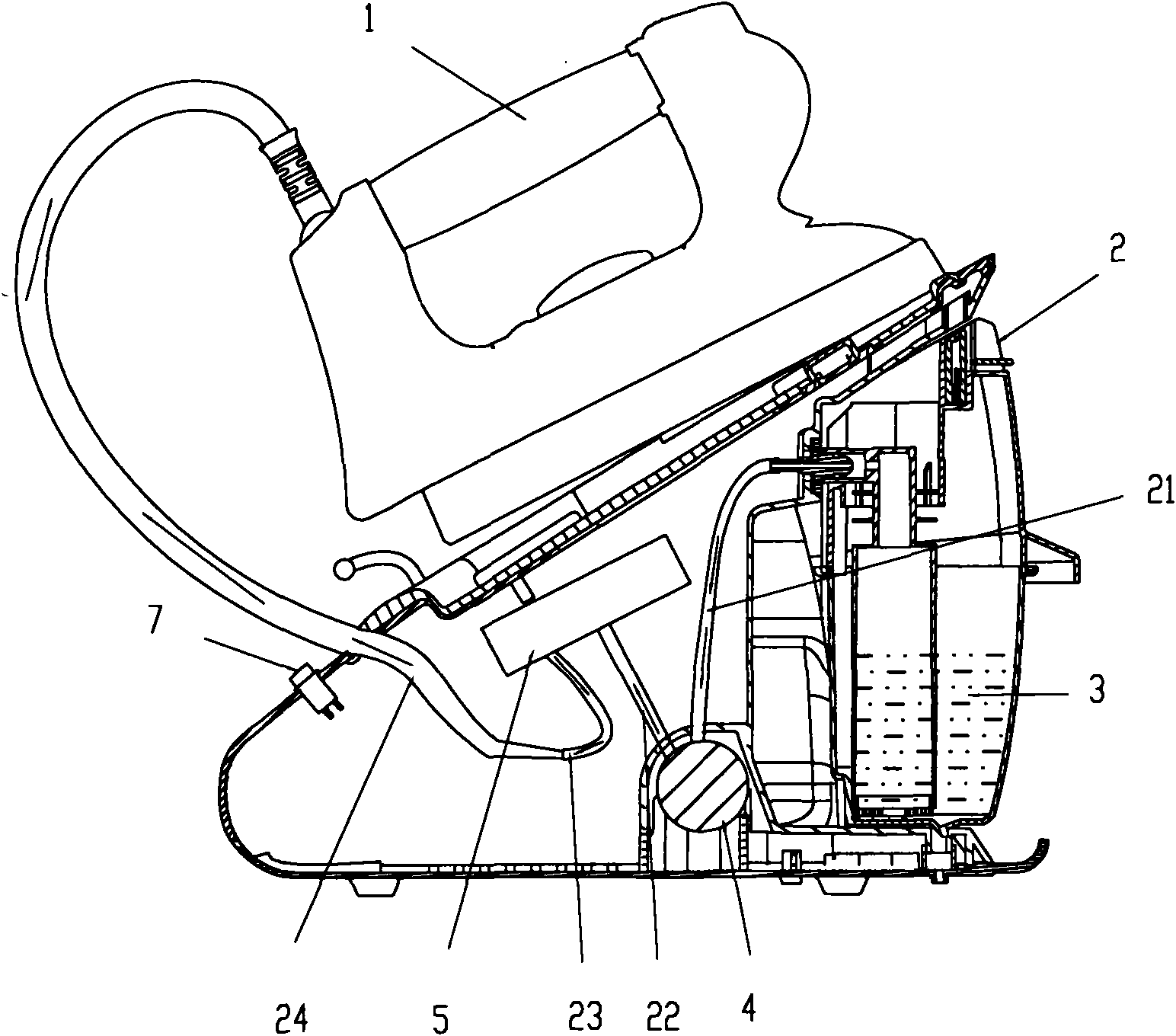

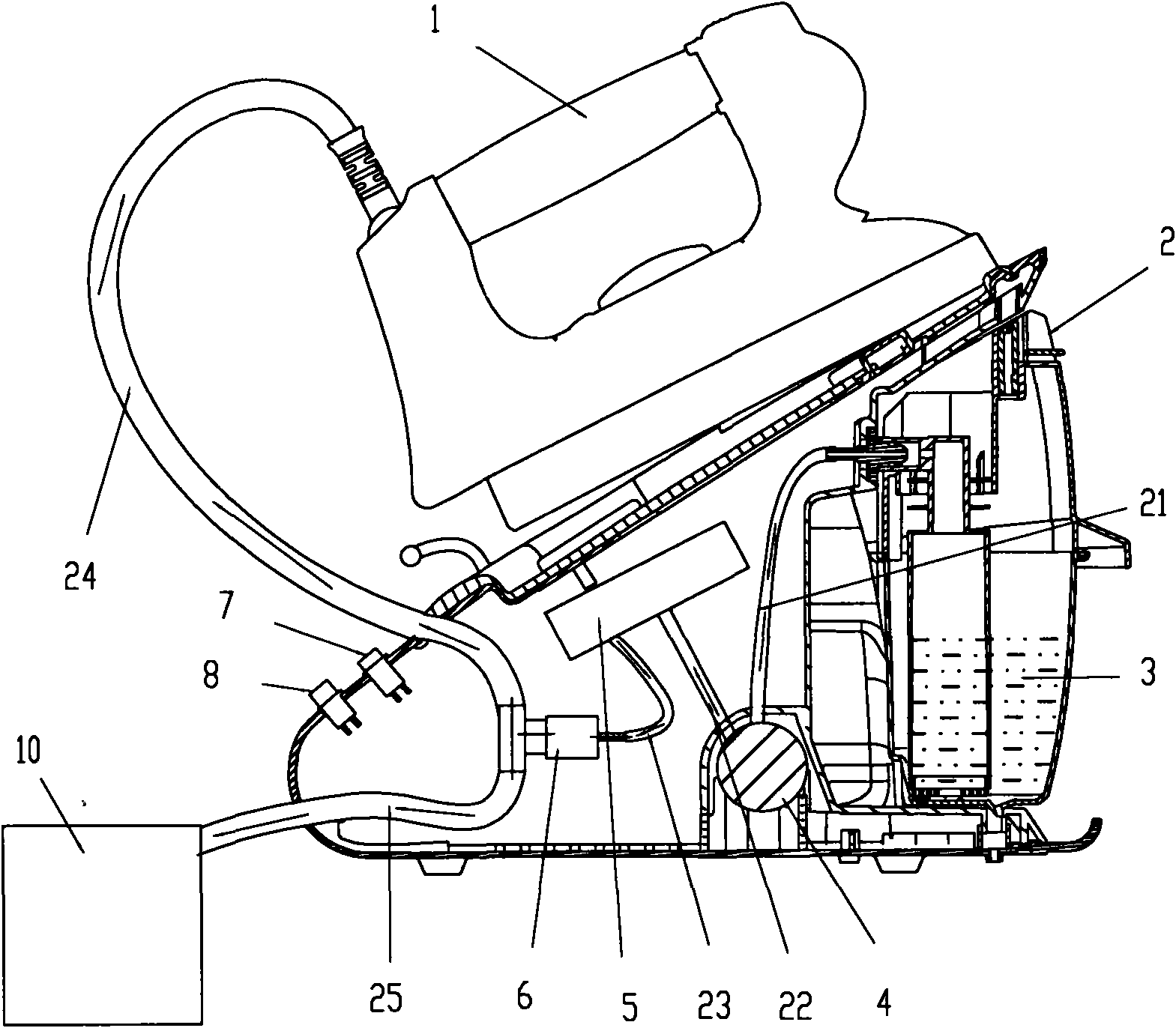

[0017] The present invention can remove the structure of an embodiment of the steam station of calcareous scale, as figure 2 shown. The casing 2 of the steam station is provided with a water tank 3 , a water pump 4 , a boiler 5 , a three-way solenoid valve 6 , a power switch 7 and a decalcification switch 8 .

[0018] Inside the housing 2 : the first water pipe 21 communicates with the water outlet of the water tank 3 and the water inlet of the water pump 4 . The second water pipe 22 communicates with the water outlet of the water pump 4 and the water inlet of the boiler 5 . The third water pipe 23 communicates with the steam outlet of the boiler 5 and the inlet of the three-way solenoid valve 6 . The first outlet of the three-way solenoid valve 6 communicates with the steam pipe 24 , and the leading end of the steam pipe 24 communicates with the external electric iron 1 . The second outlet of the three-way solenoid valve 6 communicates with the drain pipe 25 , and the lea...

Embodiment 2

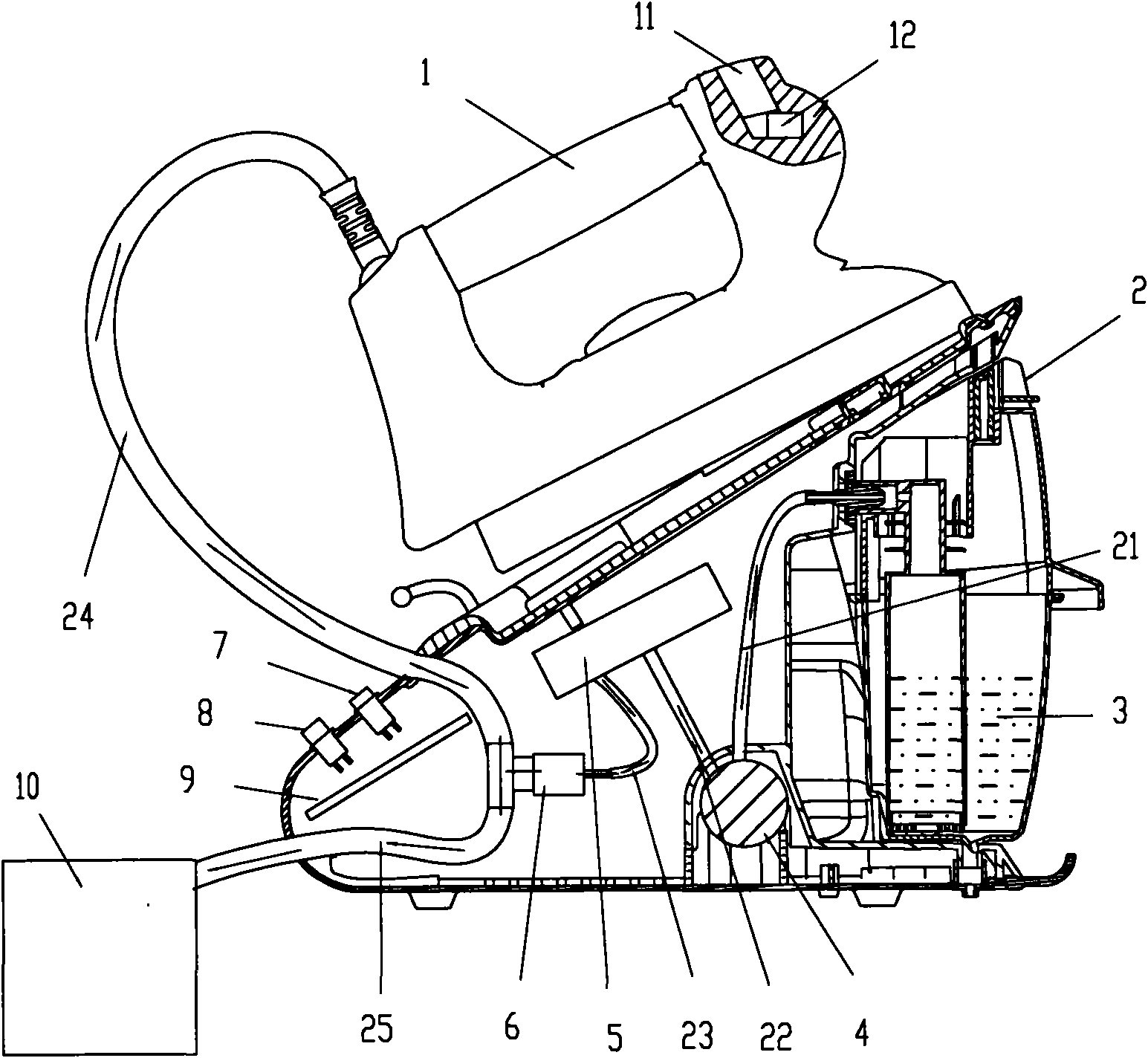

[0023] The present invention can remove the structure of the second embodiment of the steam station of calcareous scale, as image 3 shown. The casing 2 of the steam station is provided with a water tank 3 , a water pump 4 , a boiler 5 , a three-way solenoid valve 6 , a power switch 7 , a decalcification switch 8 and a control circuit board 9 .

[0024] Inside the housing 2 : the first water pipe 21 communicates with the water outlet of the water tank 3 and the water inlet of the water pump 4 . The second water pipe 22 communicates with the water outlet of the water pump 4 and the water inlet of the boiler 5 . The third water pipe 23 communicates with the steam outlet of the boiler 5 and the inlet of the three-way solenoid valve 6 . The first outlet of the three-way solenoid valve 6 communicates with the steam pipe 24 , and the leading end of the steam pipe 24 communicates with the external electric iron 1 . The second outlet of the three-way solenoid valve 6 communicates w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com