Assembled bulletproof flashboards

A bullet-proof plug-in, assembled technology, which is applied to defenses, defense devices, protective equipment, etc., can solve the problems of the inability to realize the structure of the bullet-proof plug-in, and achieve the effects of increased cost, rapid disassembly and assembly, and good integrity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

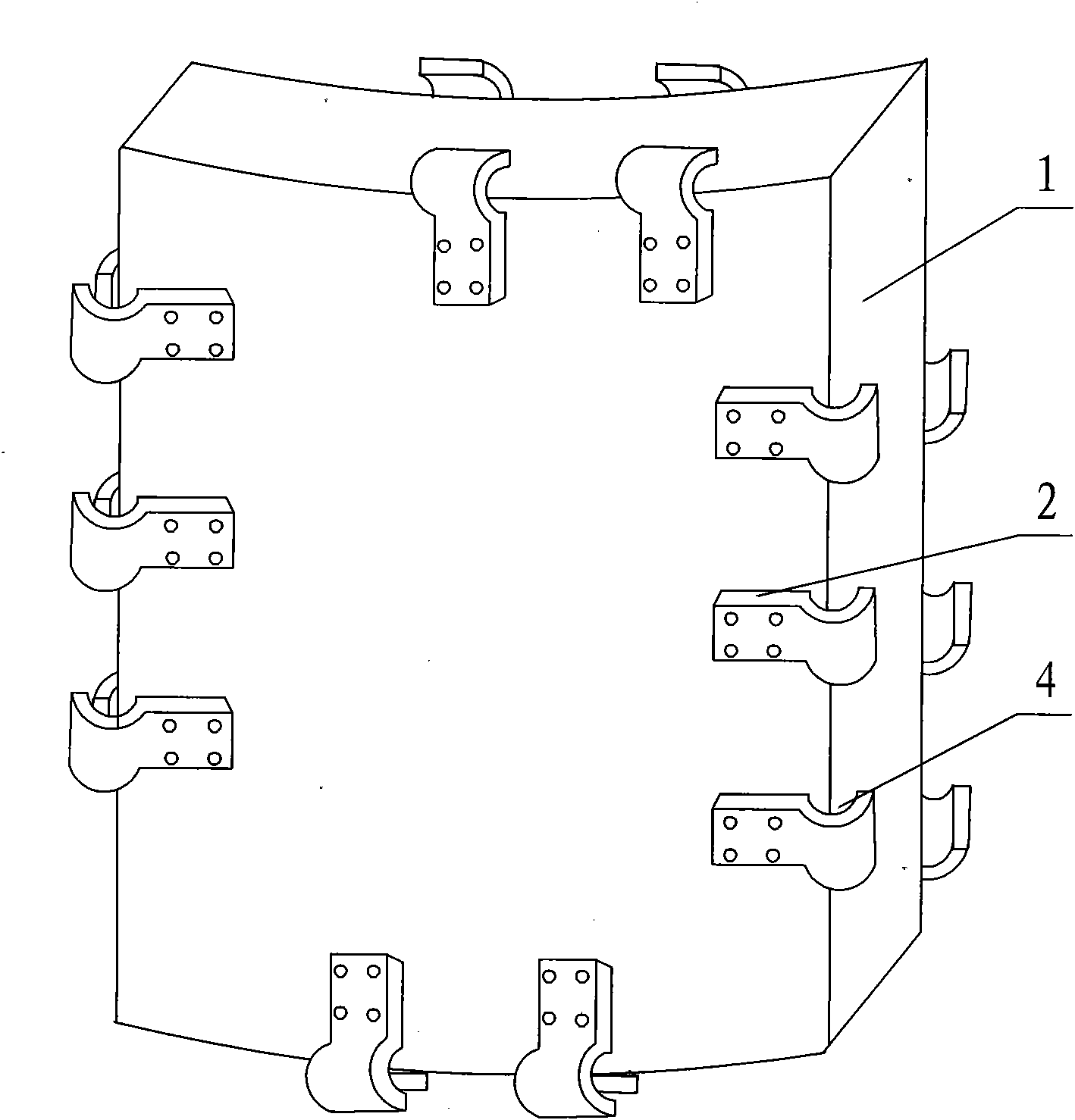

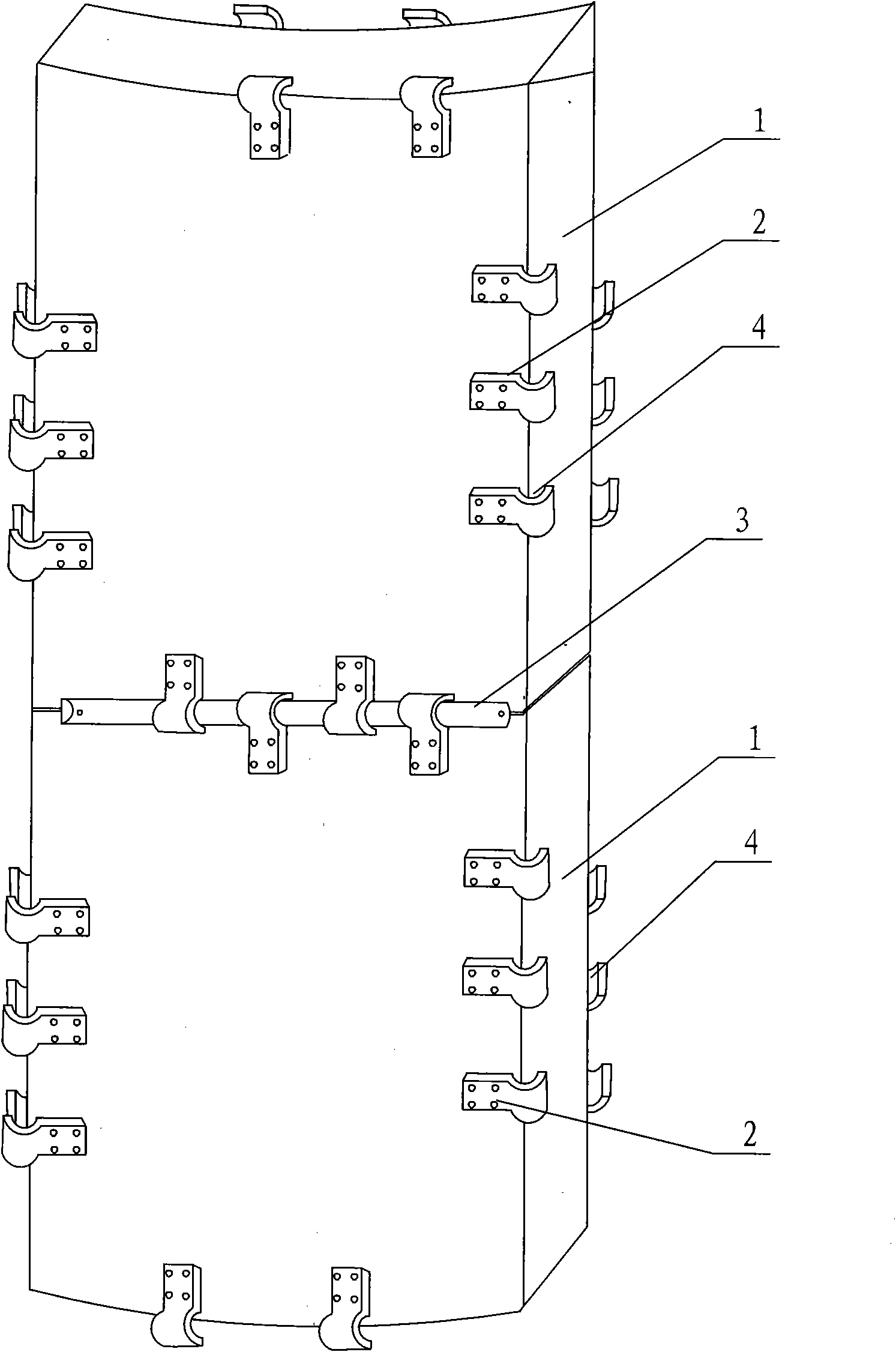

[0023] see figure 1 , there are socket joints 2 distributed on the periphery of the front and back sides of the main body of the bulletproof board 1, one end of each socket joint 2 is fixed on the main body 1 of the bulletproof board, and the other end with the socket 4 extends to the bulletproof board The main body 1 is outside the body; the distance between two adjacent socket joints 2 fixed on the plugboard is not less than the width of the socket joint 2, and the relative positions of each socket joint 2 on the opposite sides of the plugboard are staggered, It is convenient to connect with another board. Each bulletproof plate main body 1 and the socket joint 2 thereon can be assembled and formed by bolts, or can be formed as a whole by one-time casting of a mold. The main body 1 of the plugboard is made of UHMWPE and aramid fiber, and the socket joint 2 is made of reinforced PA.

[0024] see figure 2 , image 3 , Figure 4 , according to actual combat needs, through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com