Device for indirectly testing one-time purification efficiency of air purifying component and method thereof

A technology for air purification and purification efficiency, applied in the field of testing the performance of air purification components, can solve the problems of inaccurate calculation of primary efficiency, difficulty in achieving accuracy and stability of pollutant concentration, and error in calculation of primary efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

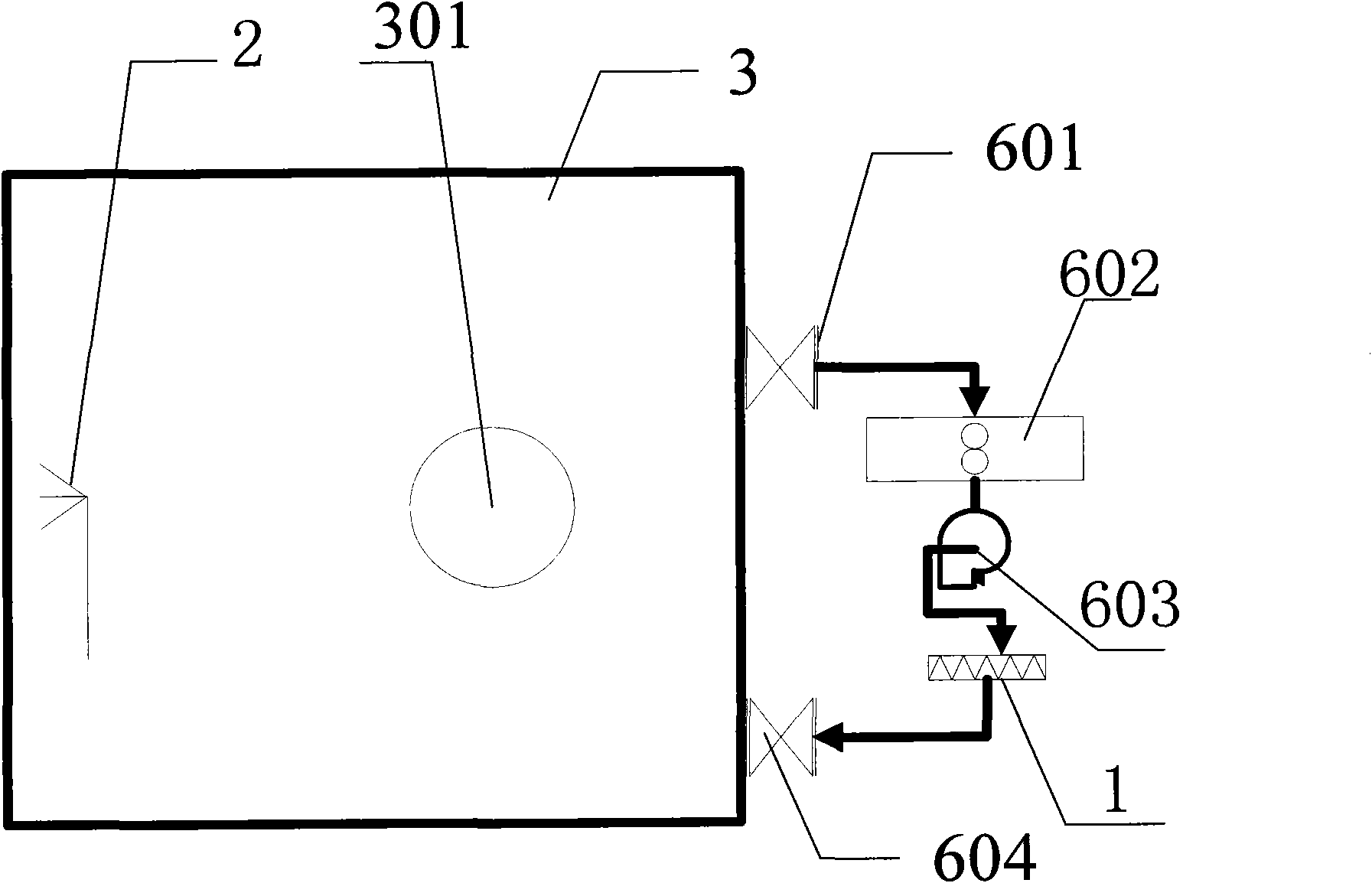

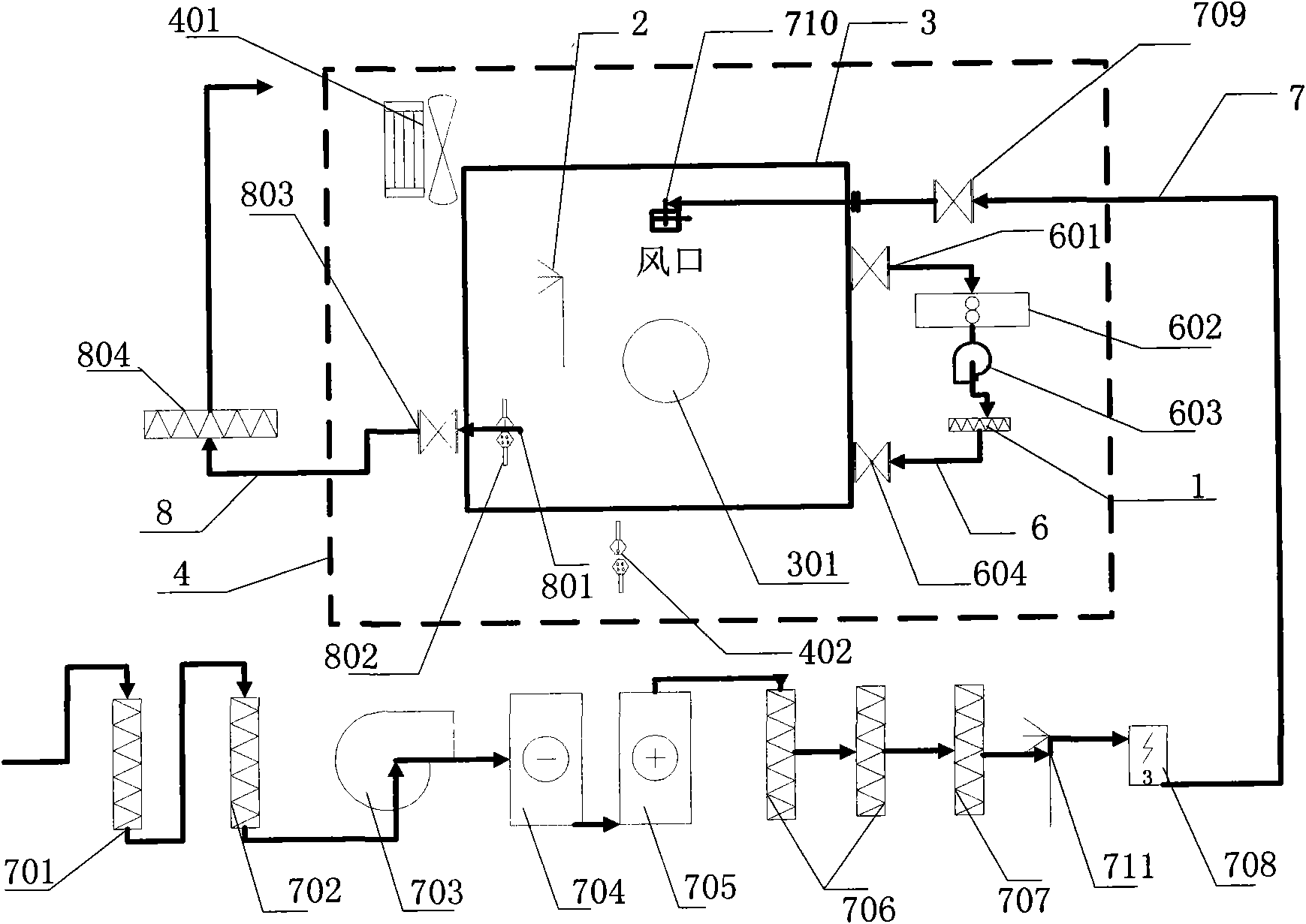

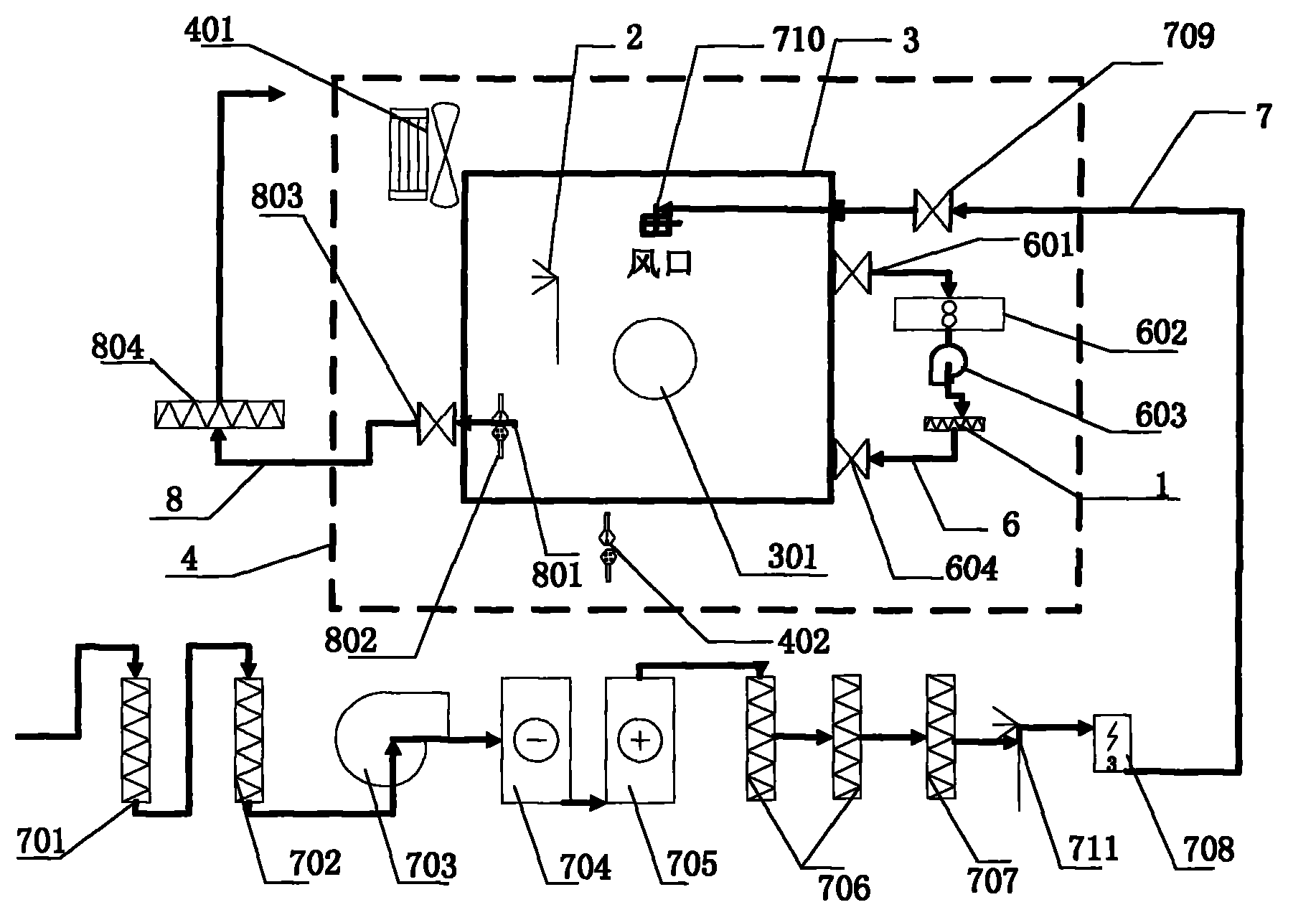

[0037] like figure 2 As shown, the pollutant generating device 2 and the mixing device 301 are placed in the airtight test chamber 3;

[0038] Connect valve A 601, flow meter 602, fan 603, air purification component 1 to be tested and valve B 604 with pipelines in order to form a test channel 6, and connect valve A and valve B to the test cabin respectively; the test channel and the test cabin In the environment adjustment room 4, an environment monitoring temperature and humidity meter 402 and a fan coil unit 401 are installed between the environment adjustment room and the test cabin;

[0039] Along the direction of the air intake, connect the primary effect filter 701, medium effect filter 702, fan B 703, surface cooler 704, water heater 705, carbon adsorption filter 706, high efficiency filter 707, humidifier 711, electric The heater 708, the valve C 709, and the tuyere 710 form an adjustment channel; the adjustment channel 7 is connected to the test cabin, and the tuyer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com