Integrated supply chain performance indicator evaluation method based on improved grey correlation analysis method

A technology of performance indicators and supply chain, applied in the field of information management system, can solve the problems of lack of system, lack of intelligent simulation, little consideration of the impact of operation performance, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

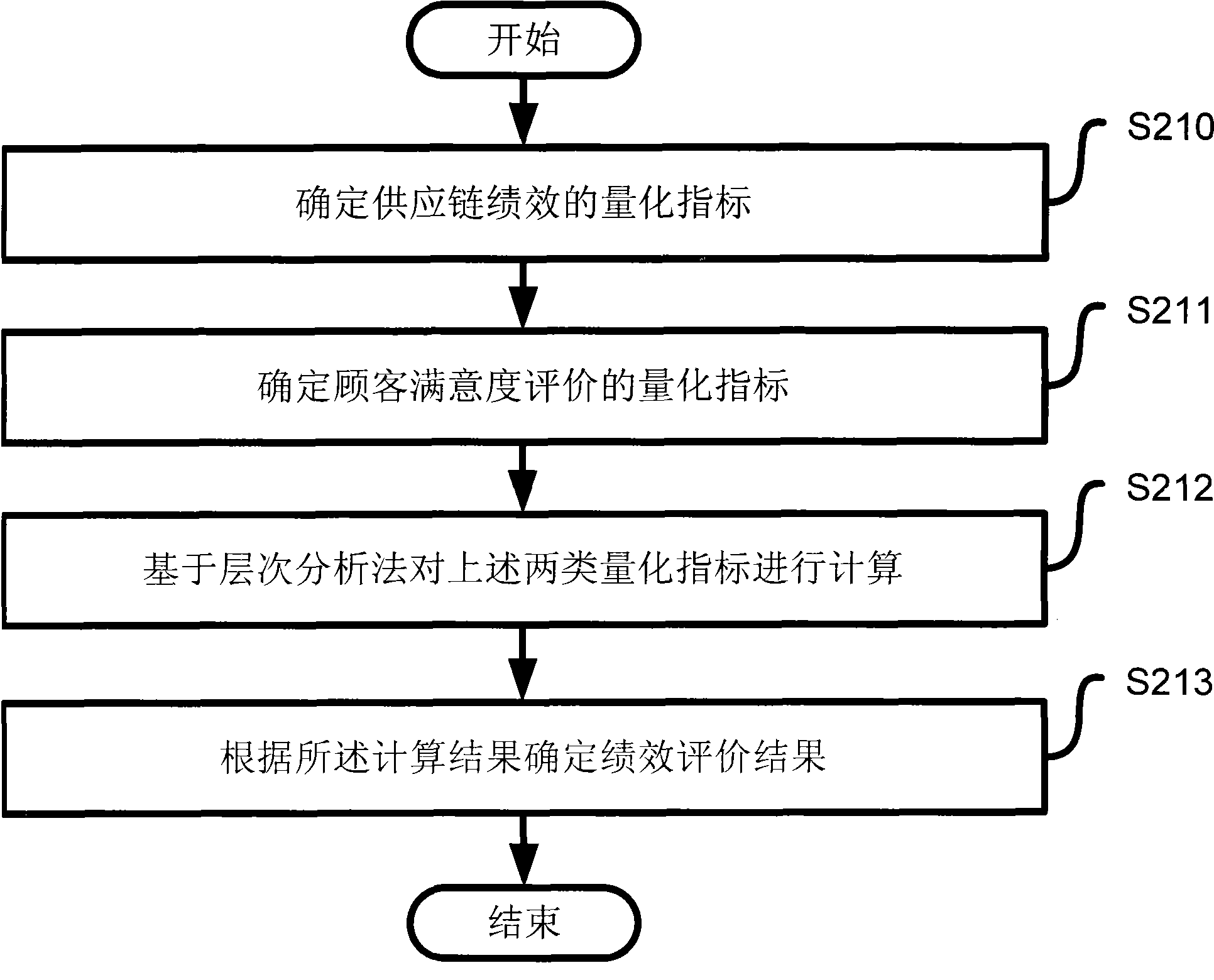

[0018] figure 1 A flow chart of an integrated supply chain performance evaluation method according to the first embodiment of the present invention is shown. Specifically, step S210 is first performed to determine quantitative indicators of supply chain performance. Those skilled in the art understand that the value of the supply chain reflects the internal performance of the integrated supply chain and is the source of supply chain development and acquisition of competitive advantages. A typical supply chain is composed of core enterprises, suppliers, and retailers. Therefore, the quantitative indicators for determining the performance of the supply chain include the quantitative indicators for determining the performance of core enterprises, the quantitative indicators for supplier performance, and the quantitative indicators for retailer performance.

[0019] Among them, the core enterprise plays the role of "fixing star" in the supply chain. The performance of the core en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com