Split type winding structure

A winding structure and primary winding technology, which is applied in the direction of transformer/inductor coil/winding/connection, coil manufacturing, etc., can solve the problems of increased investment cost, unbalanced ampere-turns, and not very applicable, so as to reduce loss and investment Cost, effect of preventing winding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail through specific embodiments below.

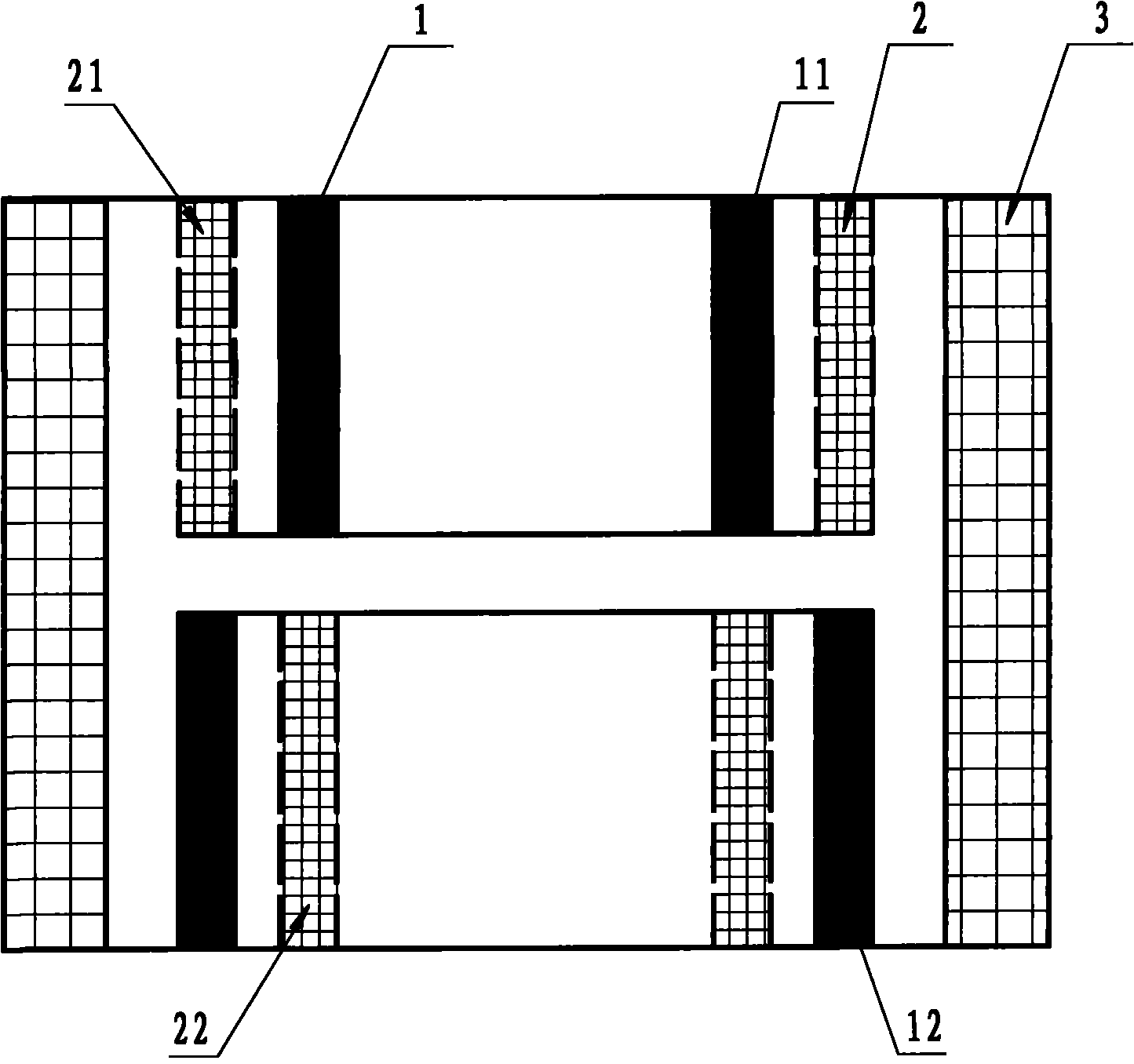

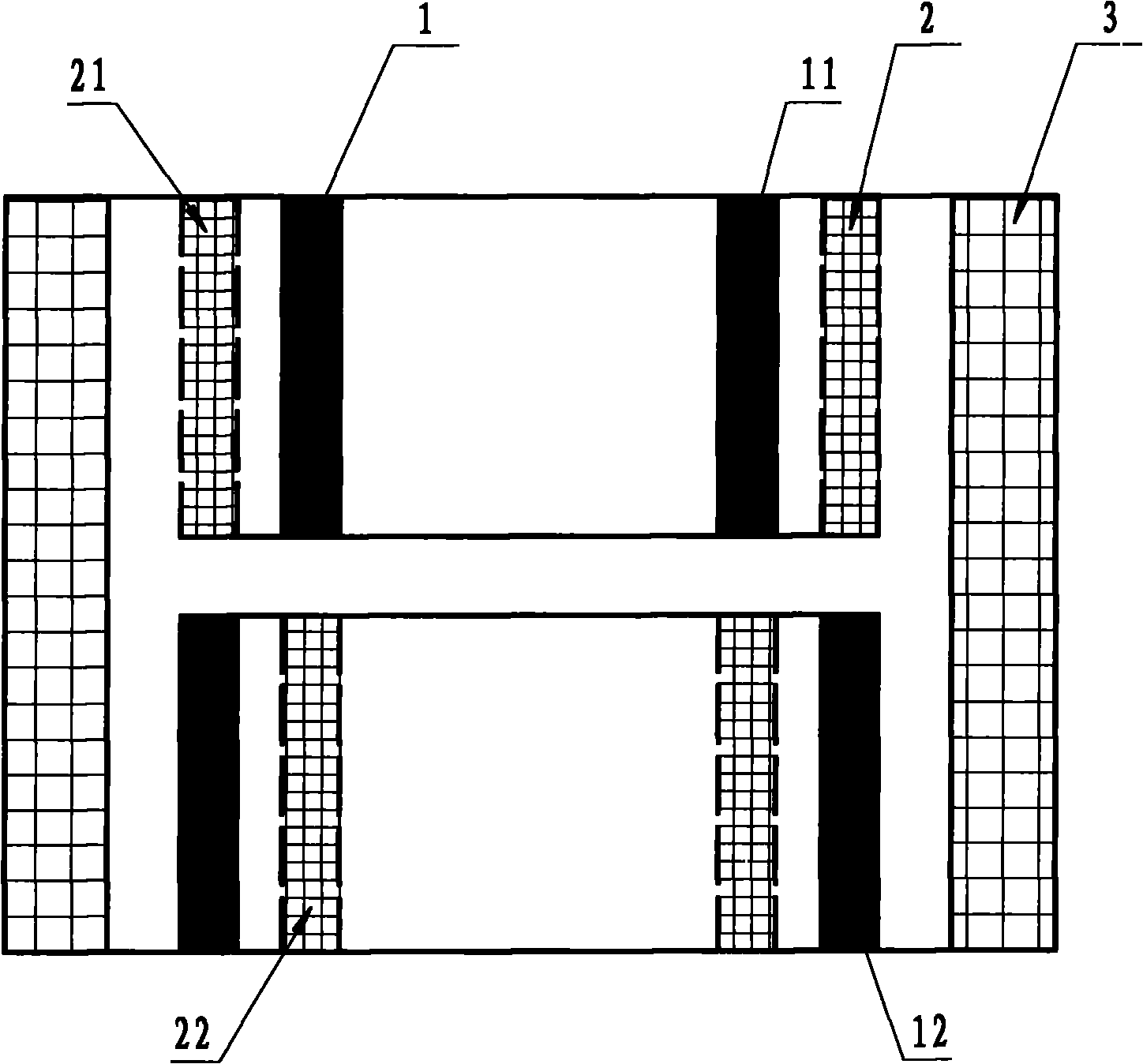

[0014] see figure 1 , the figure shows a split winding structure of the present invention, including the first primary winding 1, the second primary winding 2 and the secondary winding 3, wherein the first primary winding 1 includes series or parallel windings wound in layers The first primary winding first part 11 and the first primary winding second part 12, the second primary winding 2 includes layered winding series or parallel second primary winding first part 21 and second primary winding second part 22, secondary The primary winding 3 is wound on the outside of the split winding structure, and the first primary winding 1 and the second primary winding 2 are wound on the inside of the split winding structure 3, wherein:

[0015] The first part 11 of the first primary winding is wound inside the first part 21 of the second primary winding, and the second part 12 of the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap