Device for manufacturing waterproof connector component

A technology for waterproof connectors and manufacturing devices, applied in the manufacture of contact boxes/bases, etc., can solve problems such as reduced sealing performance, damage to resin parts, and difficulty in ensuring stable quality, and achieves the ability to inhibit damage and cutting, and inhibit damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

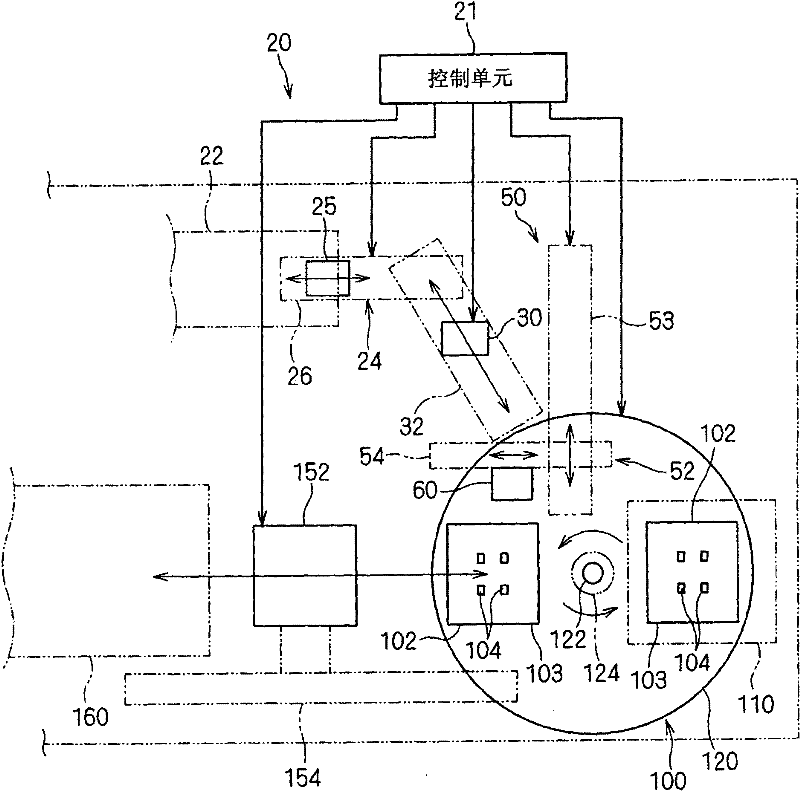

[0048] The waterproof connector component manufacturing apparatus according to the embodiment will be described.

[0049]

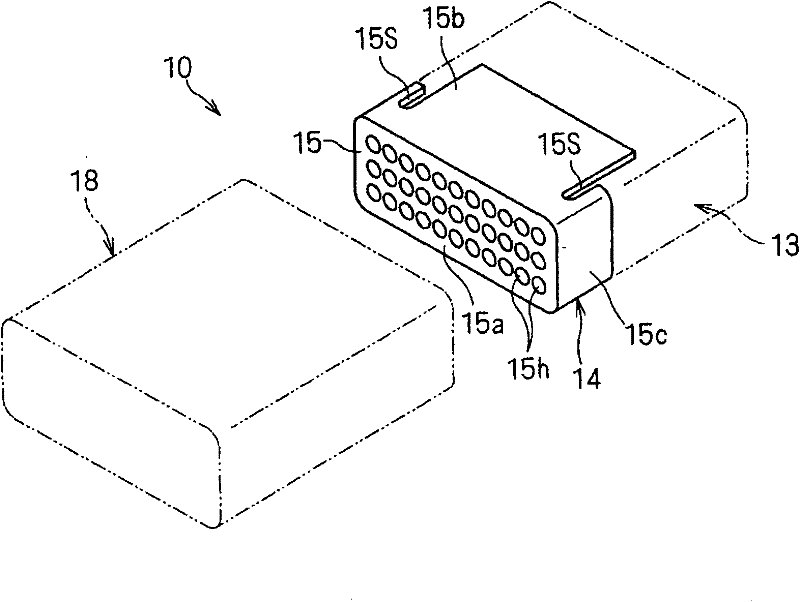

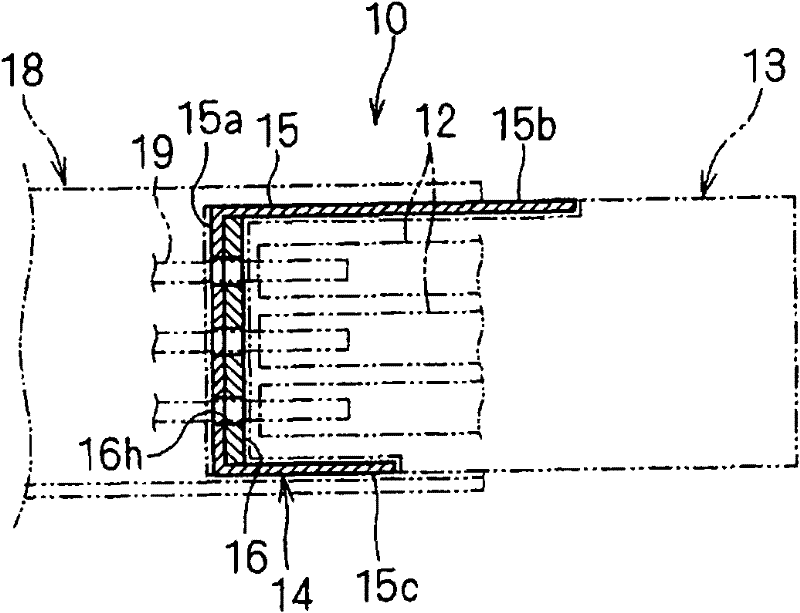

[0050] The waterproof connector part manufacturing apparatus is used to manufacture a part of the waterproof connector. For the convenience of description, an example of the waterproof connector will be described first. figure 1 is a schematic perspective view showing the waterproof connector 10, figure 2 It is a sectional view showing main parts of the waterproof connector 10 .

[0051] The waterproof connector 10 is configured by connecting a first connector 11 incorporating a female terminal 12 and a second connector 18 incorporating a male terminal 19 so that connector connection and disconnection are possible.

[0052] The first connector 11 has a case main body portion 13 and a waterproof member 14 as a connector member. The case main body portion 13 is a member formed of resin or the like, and holds the female terminals 12 in a predetermined arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com