Steel strip disc recoiling machine

A technology for a coiler and a steel strip, which is applied in the field of steel strip coilers, can solve the problems of difficulty in meeting the production needs of a single continuous operation of coiled tubing, and achieve the effects of convenient adjustment and good safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

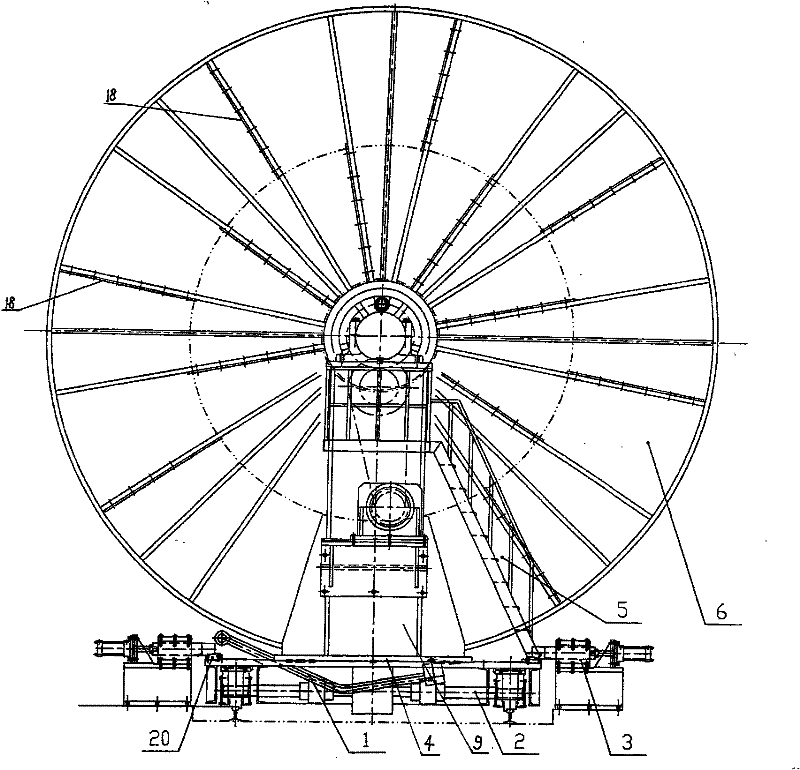

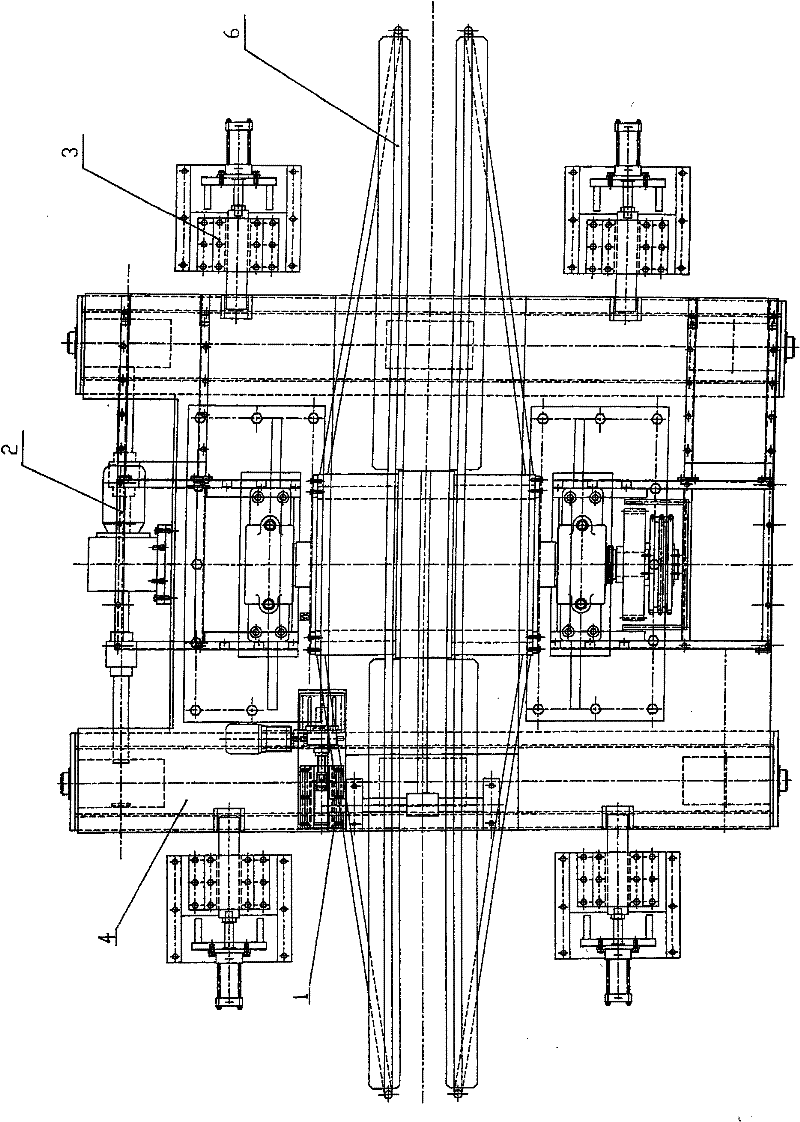

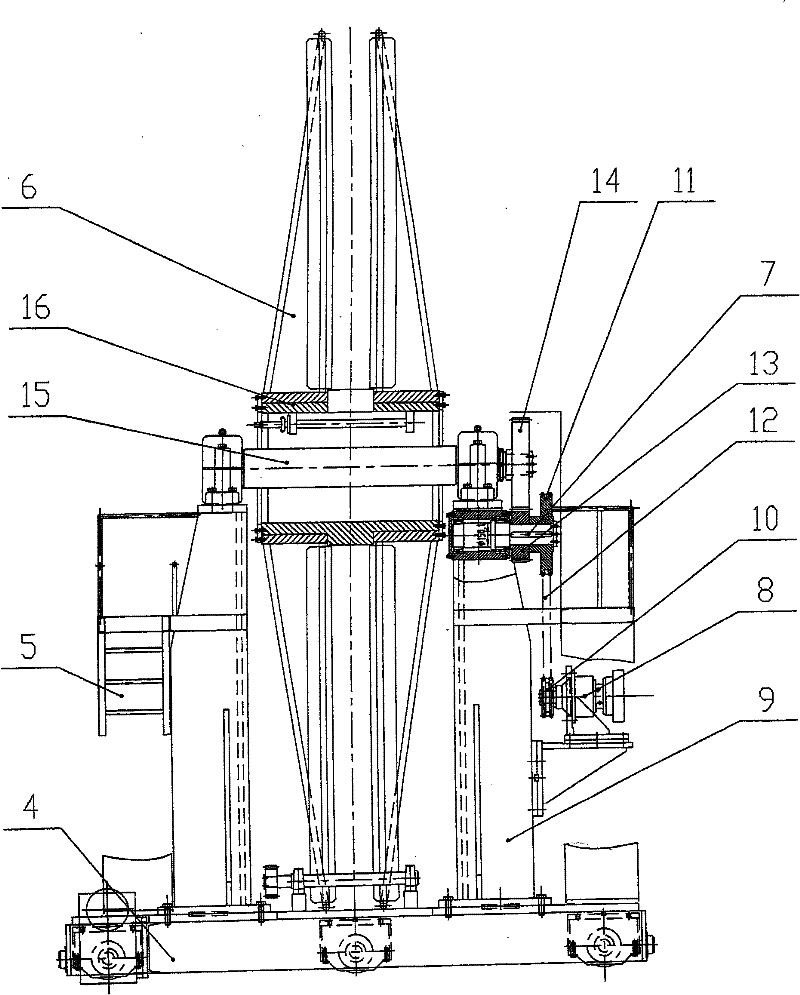

[0024] combined with figure 1 , 2 , 3, 4, 5, 6, 7 describe an embodiment of the present invention.

[0025] A steel strip reel coiler is composed of a vehicle body 4 , a frame 9 , a steel strip reel 6 , a traveling device 2 , a transmission device 7 and a power device 8 . The car body 4 is fixed on the running gear 2, the frame 9 is fixed on the car body 4, the steel belt reel 6 is vertically installed on the top of the frame 9, and the transmission device 7 and the power unit 8 are arranged on one side of the frame 9 for safety. The ladder 5 is arranged on the other side of the frame 9 . The active small sprocket 10 fixed on the power output shaft of the power unit 8 is connected with the passive large sprocket 11 fixed on the transmission shaft of the transmission device 7 by a chain 12, and the fixed active pinion 13 on the transmission shaft of the transmission device 7 is connected with the steel chain. The fixed passive bull gear 14 on the main shaft 15 of the tape r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com