Automatic paper feeding device with clutch

A clutch and clutch control technology, applied in the direction of pile separation, object separation, object supply, etc., can solve problems affecting accuracy, collision loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

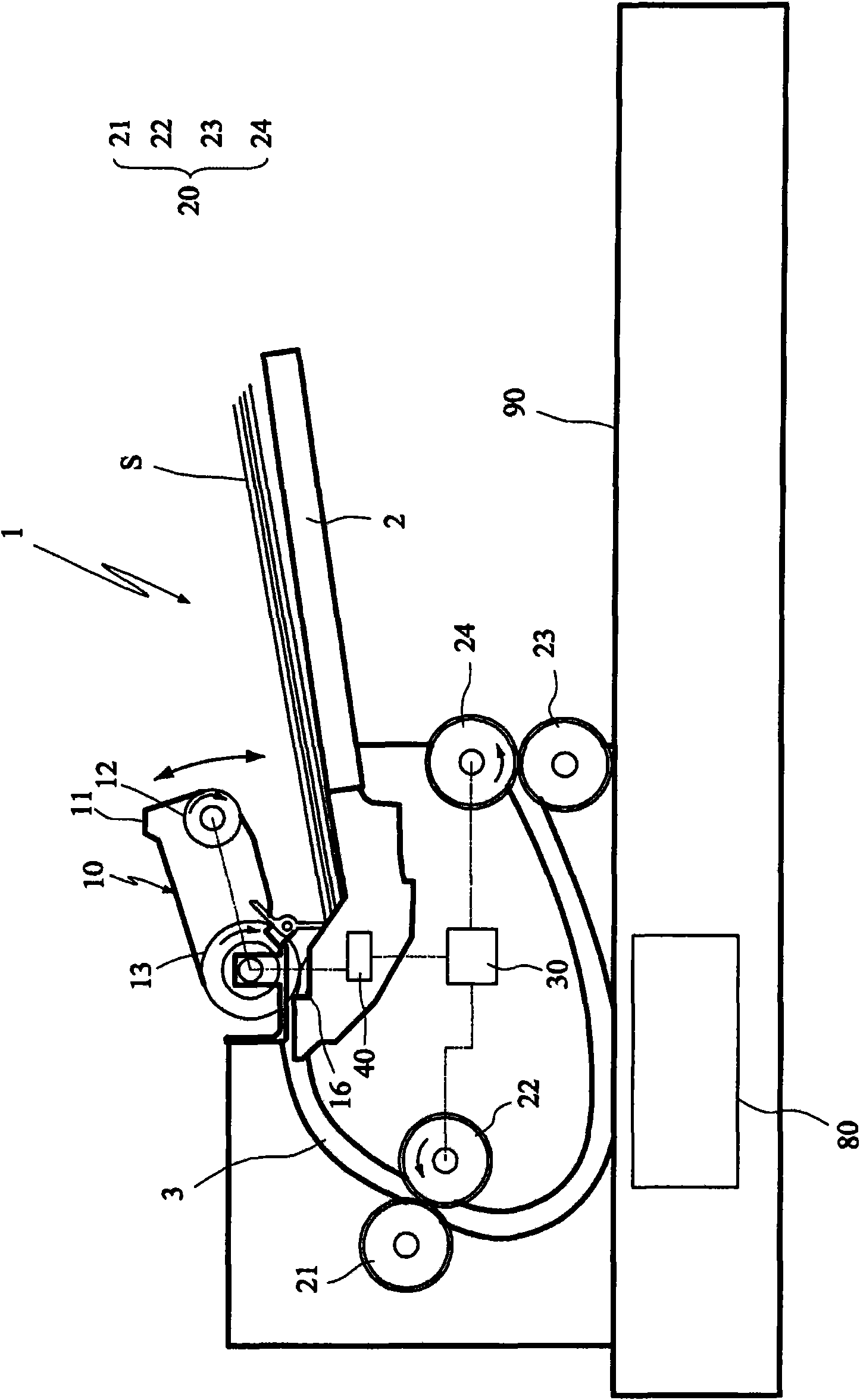

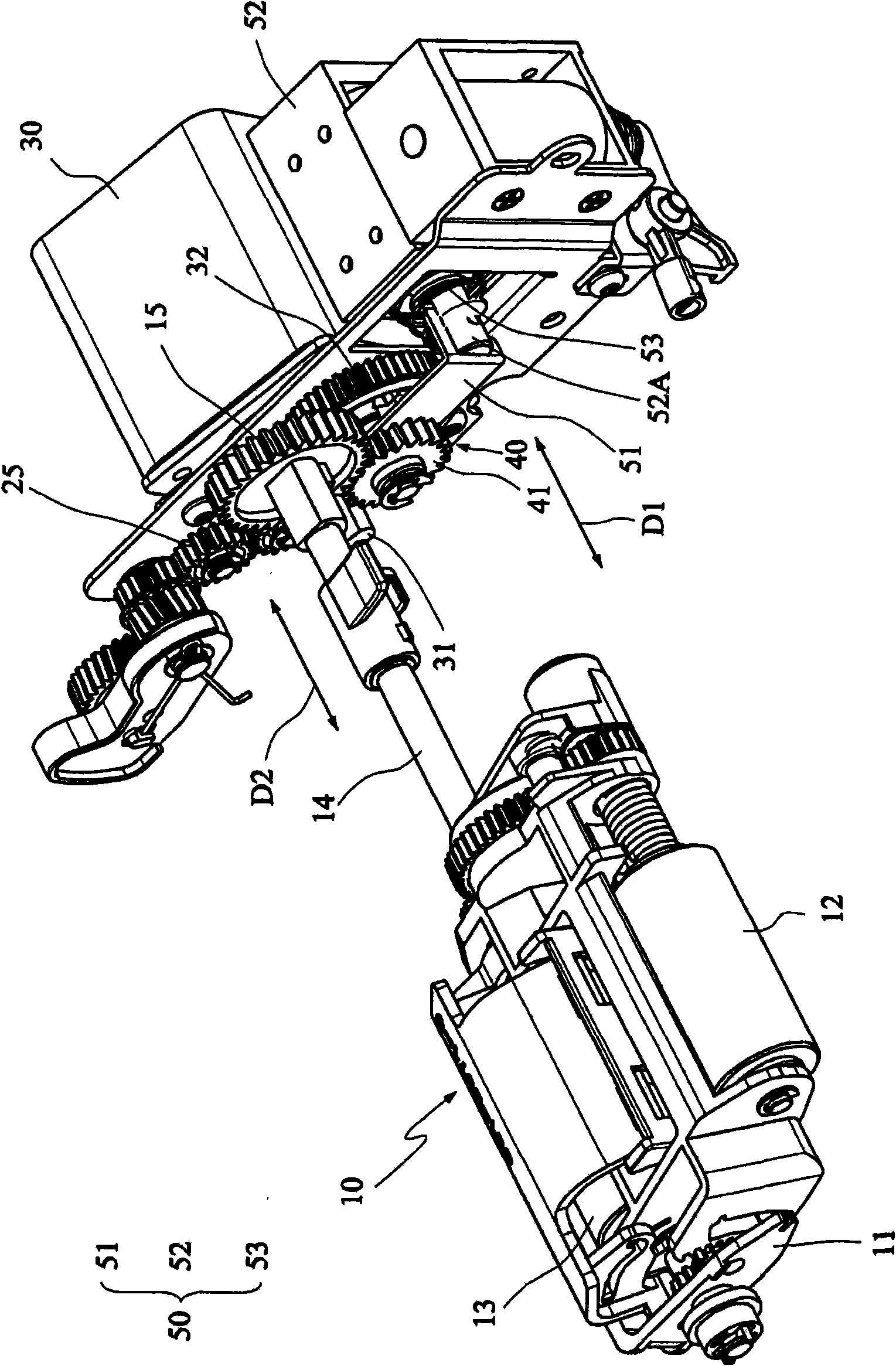

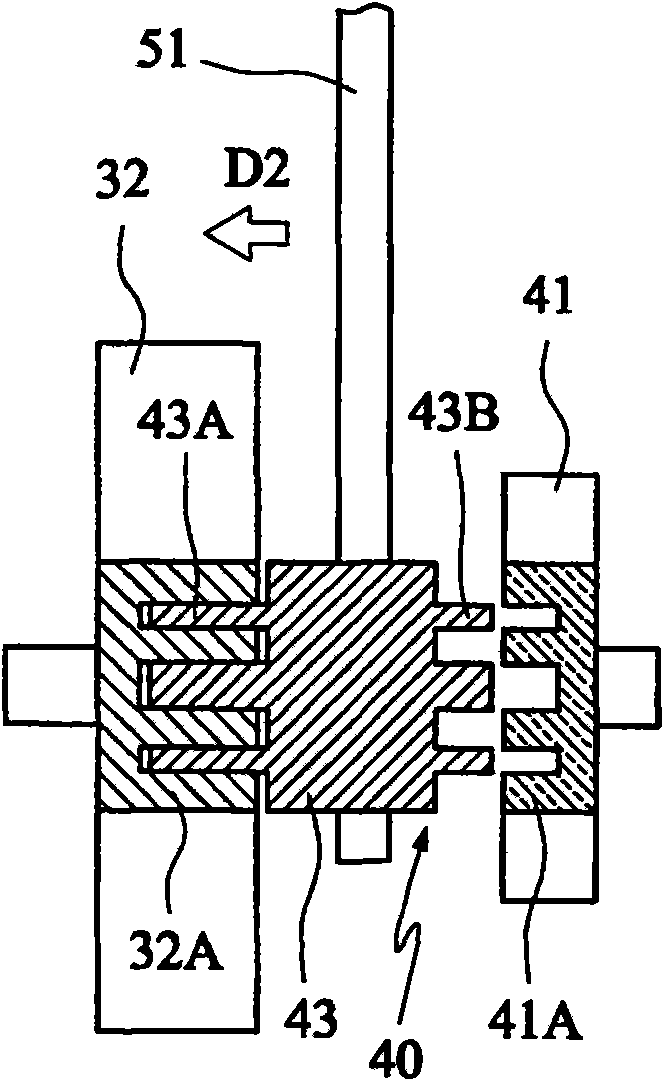

[0014] figure 1 A schematic diagram of an automatic sheet feeding device according to a preferred embodiment of the present invention is shown. figure 2 and 5 A partial three-dimensional schematic diagram of the automatic paper feeding device according to the preferred embodiment of the present invention is shown. like figure 1 , 2 As shown in FIG. 5 , the automatic paper feeding device 1 of this embodiment includes a paper picking mechanism 10 , a paper conveying mechanism 20 , a power source 30 and a clutch 40 . Of course, the automatic paper feeding device 1 may further include a casing 90 and a scanning module 80 that can move back and forth in the casing 90 .

[0015] The paper pick-up mechanism 10 is swingable for grabbing a paper S located in a paper cassette 2 and feeding the paper S into a channel 3 . In this embodiment, the paper pick-up mechanism 10 includes a power input shaft 14 and an input gear 15 . The input gear 15 is sleeved on the power input shaft 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com