Method for strengthening edges of tool and die based on laser transformation hardening

A technology of laser phase change hardening and tooling, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as consumption, and achieve the effect of ensuring optimality and small material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

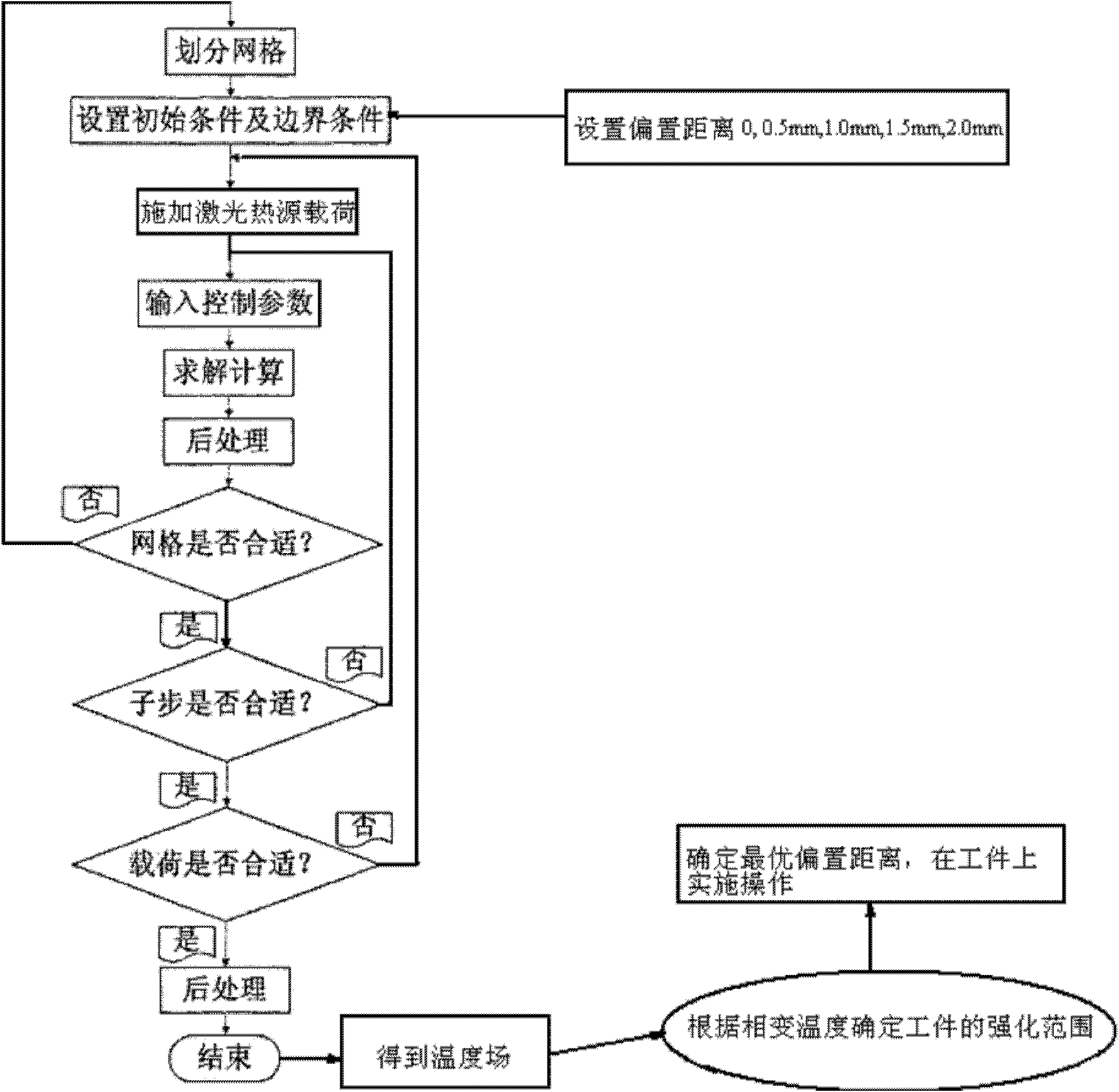

[0032] refer to figure 1

[0033] The method for strengthening the edge of the tool and mold based on laser phase transformation hardening comprises the following steps:

[0034] 1), select the laser intensified light source according to experience, set the light source parameters, the light source parameters include laser wavelength, power, scanning speed and spot diameter; obtain the parameters of the mold to be processed, the mold parameters include material properties, phase transition temperature , melting point and geometric size;

[0035] 2) Set the starting position of the strengthening light source, perform laser scanning, and pass compressed air to quickly cool the tool and mold to achieve the purpose of surface strengthening;

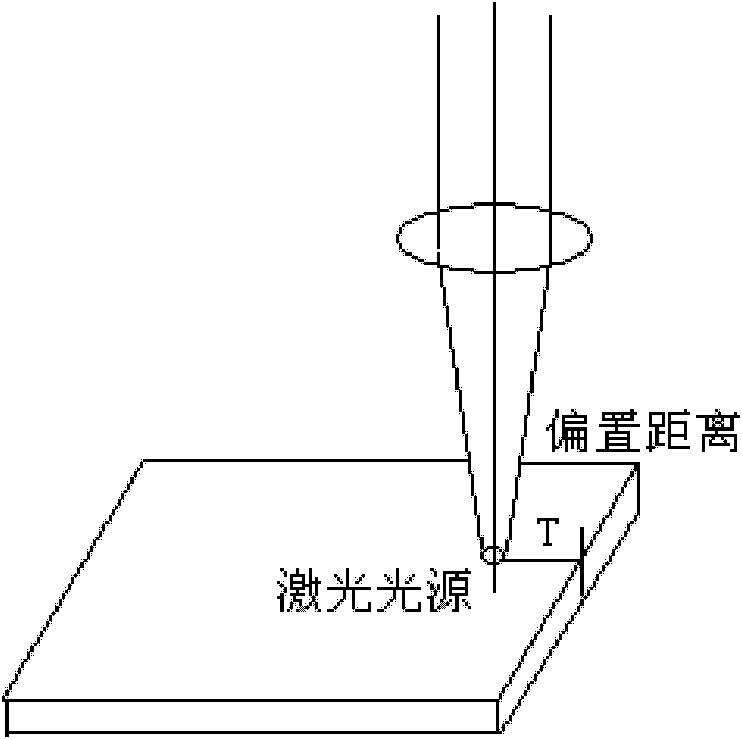

[0036] It is characterized in that: simulate and calculate the situation of the light source irradiating the tool and mold to obtain the optimal strengthening distance between the strengthening light source and the edge of the tool and mold...

Embodiment 2

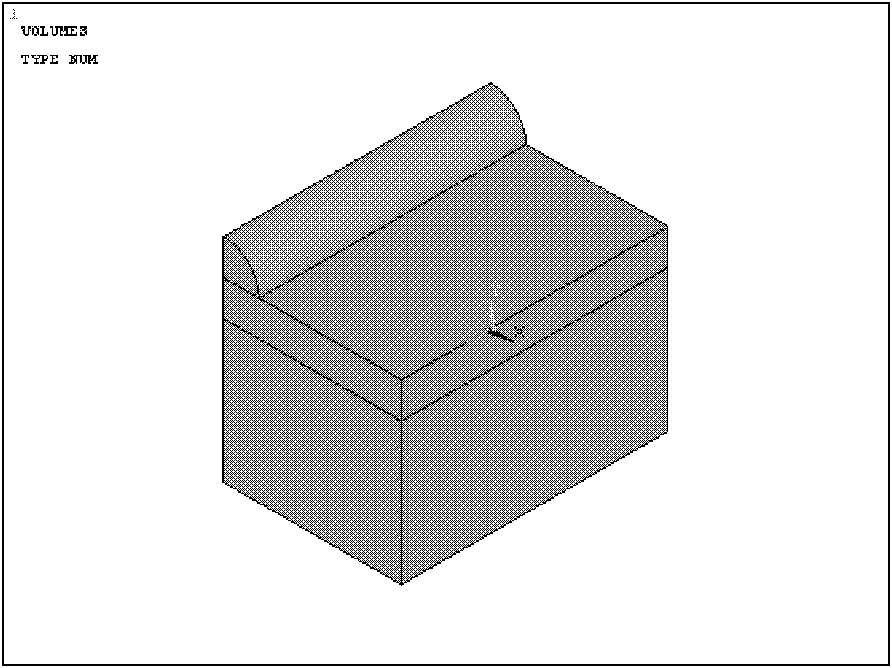

[0047] combine Figure 2-10 , and the actual test further illustrates the present invention:

[0048] Select the quality of about 0.9kg, P20 plastic tool and die steel, strengthen the workpiece size is 15mm × 10mm × 10mm, and its edge is strengthened with H13 alloy powder. According to the intensified process, using cross-flow CO 2 The laser power required by the laser is P=1.5kW, the spot diameter D=4mm, and the powder is fed synchronously. Specific steps are as follows:

[0049] (1) The simulation adopts the same process as the actual one—synchronous powder feeding method, and the surface of the same matrix material plastic tool and die steel P20 is clad with H13 powder. The laser process parameters are shown in Table 1:

[0050] Table 1 Laser process parameters

[0051] Process parameters

Laser scan rate v(m / s)

0.005

Laser power P(KW)

1.5

Spot size D(mm)

4

[0052] (2) Select a Gaussian heat source model similar t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com