Device for filling water repellent cable paste into communication optical cable

A technology for water-blocking cable paste and communication optical cable, applied in the direction of fiber mechanical structure, etc., can solve the problems of waste of water-blocking cable paste, waste of manpower and energy, performance deterioration, etc., and achieve stable operation of the device, reasonable device design, and reduced material waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

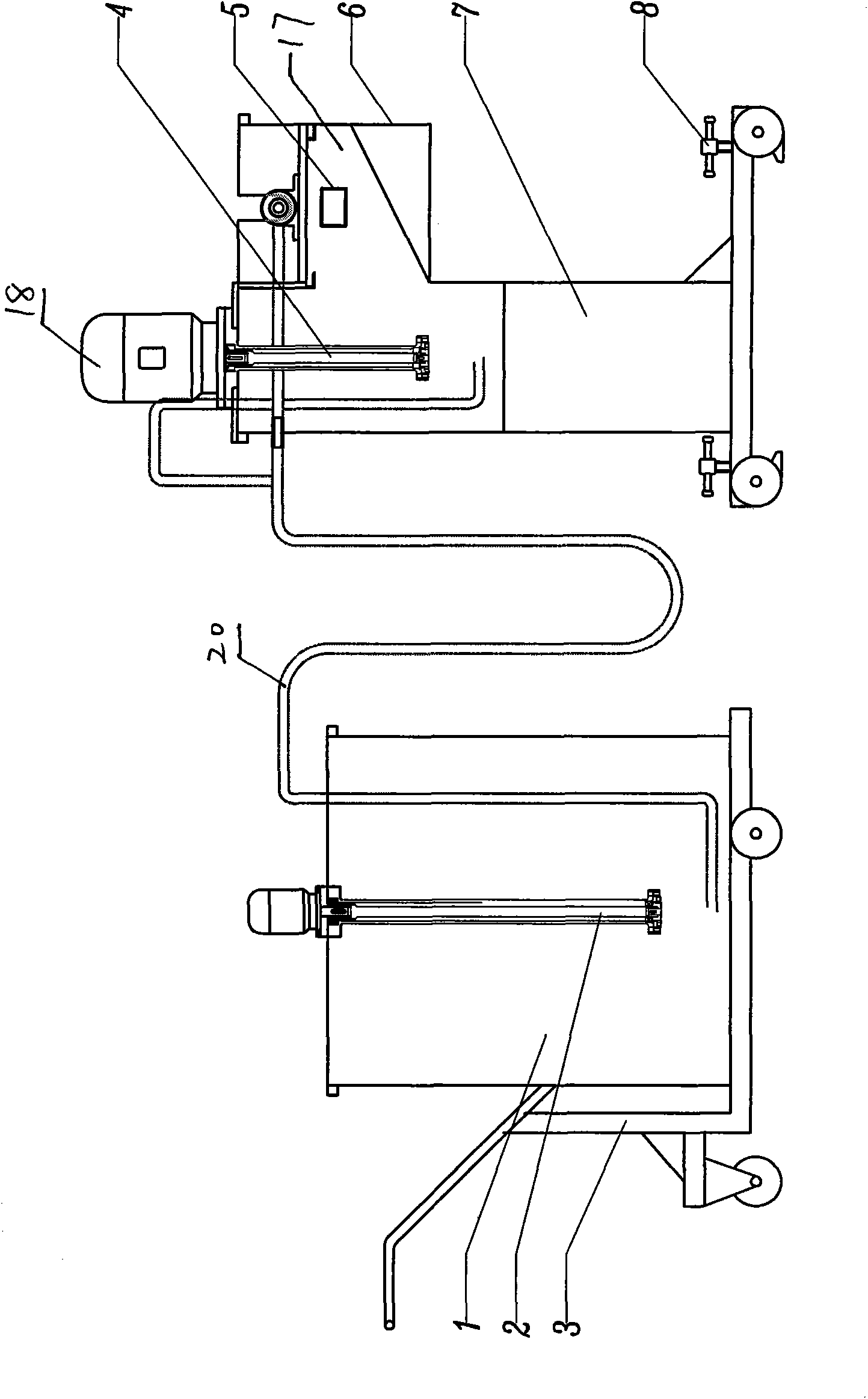

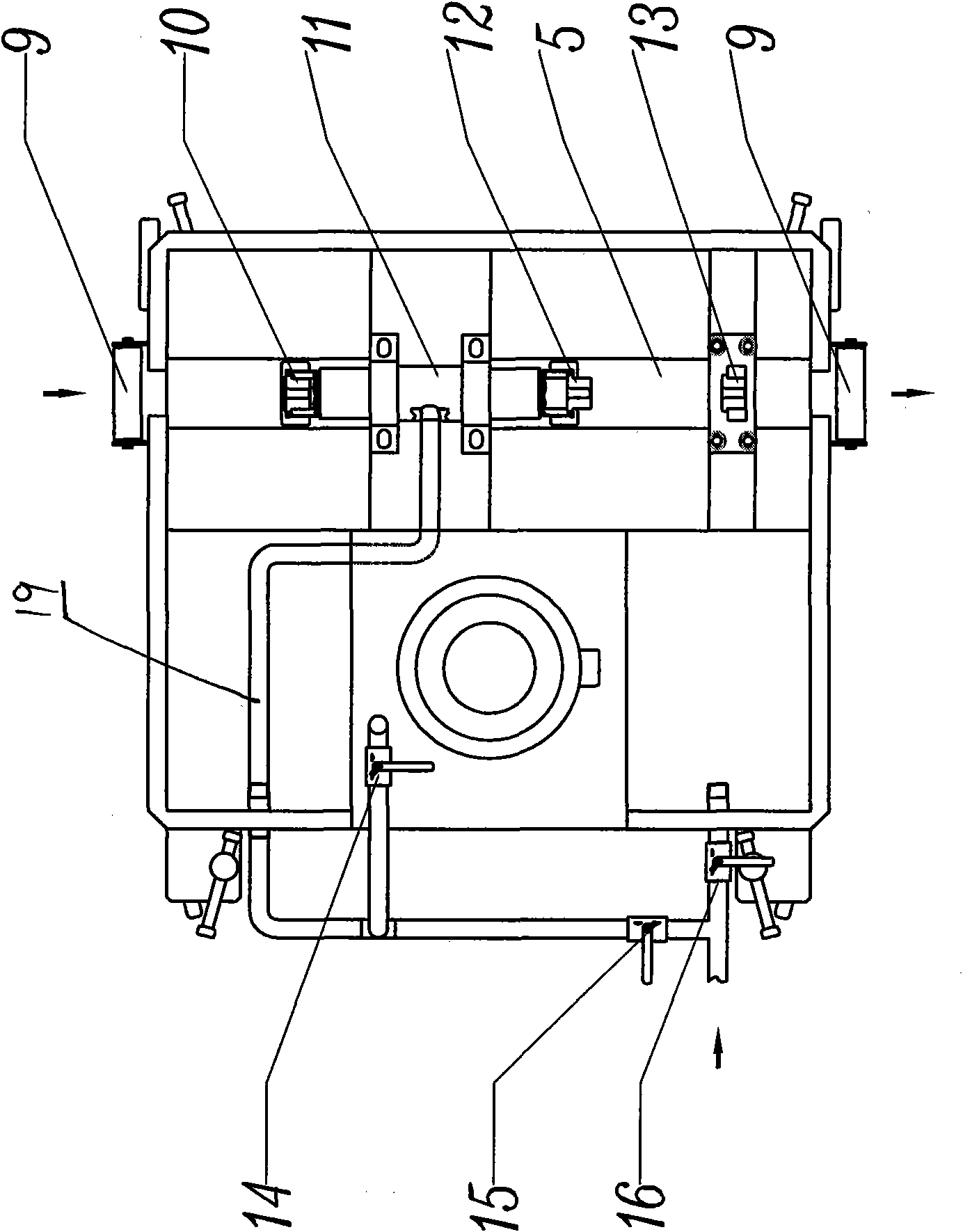

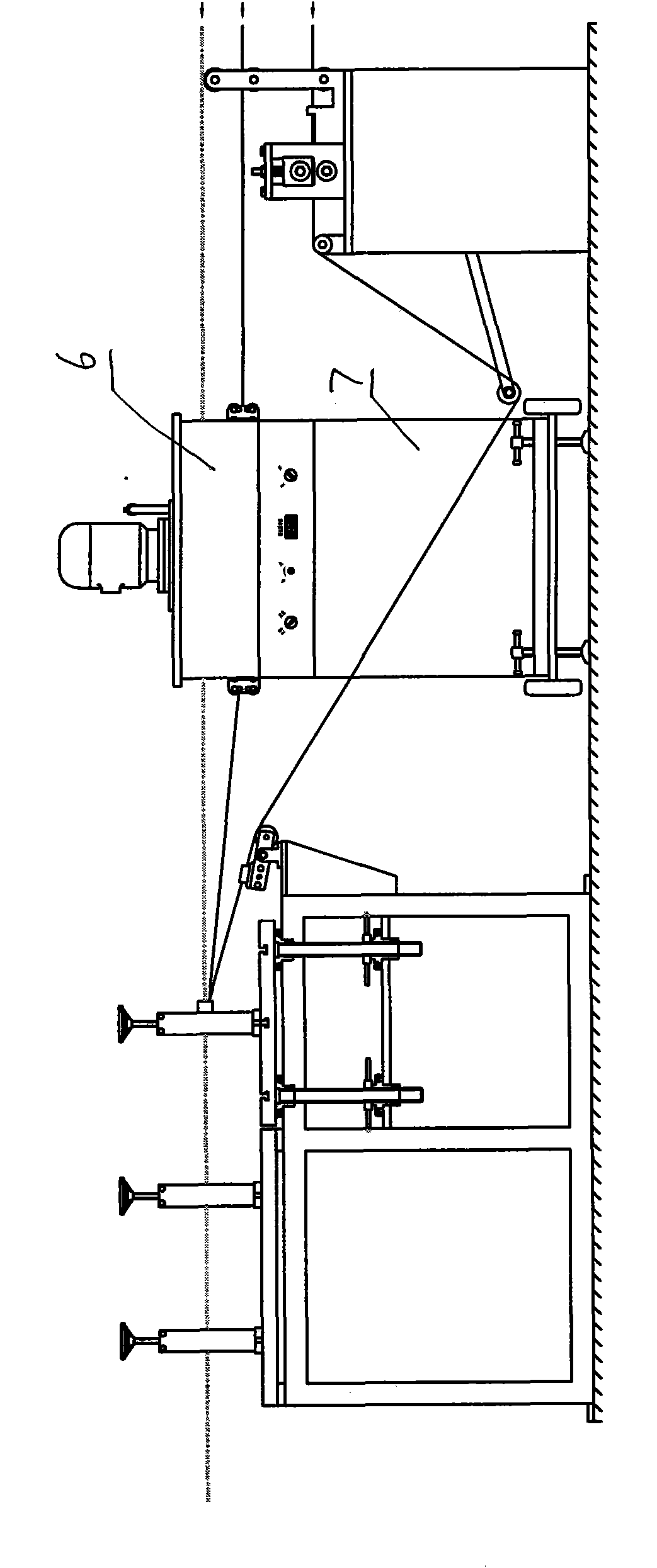

[0011] In the figure, 1. Water blocking cable paste bucket; 2. Supplementary pump; 3. Trolley; 4. Circulating filling pump; 5. Non-corrugated steel and aluminum strip channel; 6. Control panel; 7. Electric control cabinet; 8. Center Height positioning adjuster; 9. Non-corrugated steel and aluminum strip guide roller; 10. Imported sizing die and die base; 11. Water-blocking cable paste filling chamber and pressure indicator; 12. Export sizing die and die base; 13 .Scraping oil sizing die and die base; 14. Circulation pump valve; 15. Switching valve; 16. Supplementary valve; 17. Cable paste storage box.

[0012] Such as figure 1 , figure 2 As shown, the communication optical cable water-resistance cable paste filling device includes a frequency conversion motor 18, an electric control cabinet 7, a control panel 6, an adjustable pressure filling head, main and auxiliary cable paste filling, a cable paste storage box 17, and a cable paste replenishment device It consists of fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com