Automatic rotary steering petroleum drilling tool

An automatic rotation and steering drilling technology, which is applied in drilling tools, drilling equipment, earthwork drilling and production, etc., can solve the problems that the service life of the drill bit is greatly affected, and achieve the effects of increasing work efficiency, reasonable device design and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

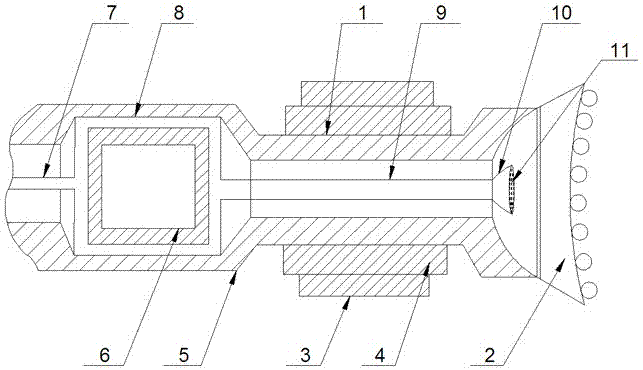

[0016] Such as figure 1 As shown, the present invention provides a petroleum automatic rotary steerable drilling tool, comprising a rotary head 1, a drill bit 2, a piston cylinder 3, an edge block 4, a rotary drill string 5, a control valve 6, a water inlet pipe 7, a return water hose 8, Connect the pipeline 9, the spray head 10 and the spray hole 11, one end of the rotary head 1 is provided with a drill bit 2, the other end of the rotary head 1 is fixedly connected with one end of the rotary drill string 5, and the inside of the rotary drill string 5 is provided with a control valve 6, The central axis of the rotary drill string 5 is provided with a water inlet pipe 7, one end of the water inlet pipe 7 communicates with one end of the return water hose 8 around the control valve 6, and the other end of the return water hose 8 connects with the connecting pipe inside the rotary head 1 One end of the road 9 communicates, and the other end of the connecting pipeline 9 communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com