Cascading type fiber laser

A fiber laser, cascade technology, used in lasers, laser parts, phonon exciters, etc., can solve the problems of unstable output power, large signal loss, damage, etc., and achieve the effect of reducing instantaneous high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

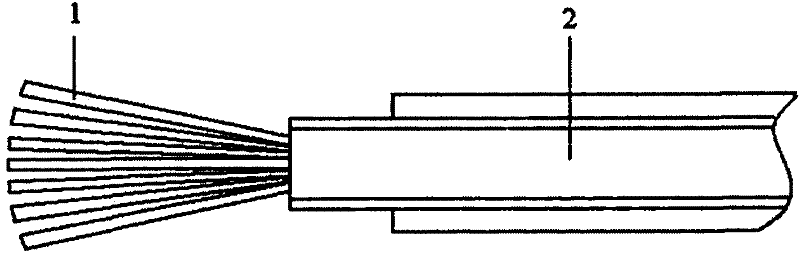

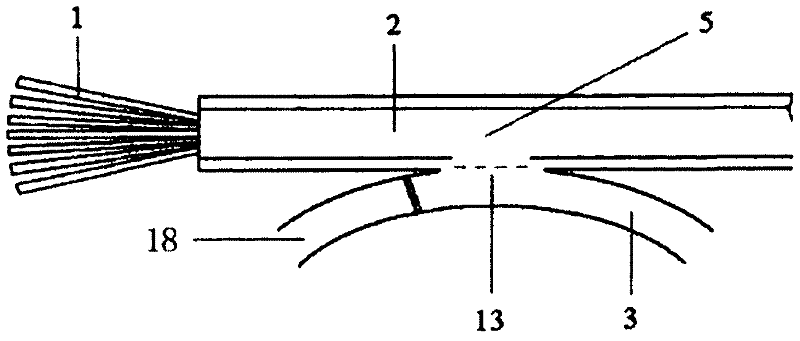

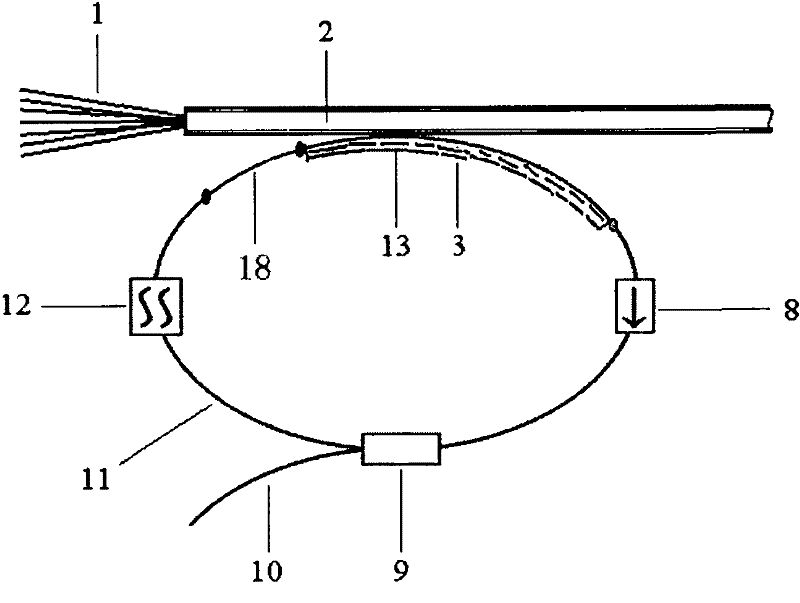

[0024] Preferred examples of the present invention, such as image 3 , Figure 4 As shown, a cascaded fiber laser includes an optical resonant cavity, 7 (other numbers can also be used) pump input fibers 1, pump output fibers 2, the 7 pump input fibers 1 and a pump 7 × 1 fiber bundle combiner (such as figure 1 shown), also includes an active double-clad fiber 3, the active double-clad fiber 3 is coupled with the side of the pump output fiber 2 to form a (1+1)×1 fiber combiner 5 (such as figure 2 shown), the optical resonator is composed of the active double-clad fiber 3 of the (1+1)×1 fiber combiner 5, an optical isolator 8, an optical coupler 9 and a narrowband optical filter 12 ring-structured optical resonators connected sequentially (such as image 3 shown), the optical coupler 9 separates a small output end 11 and a large output end 10, the small output end 11 is connected to the input end of the narrowband optical filter 12 by welding, and the large output end 10 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com