On-vehicle hedge clipping machine

A hedge trimmer and hedge trimming technology, applied in the field of vehicle-mounted hedge trimmers, can solve the problems of low automation, small operating range, and high production costs, and achieve the effects of wide operating range, simple operation, and fast transition speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

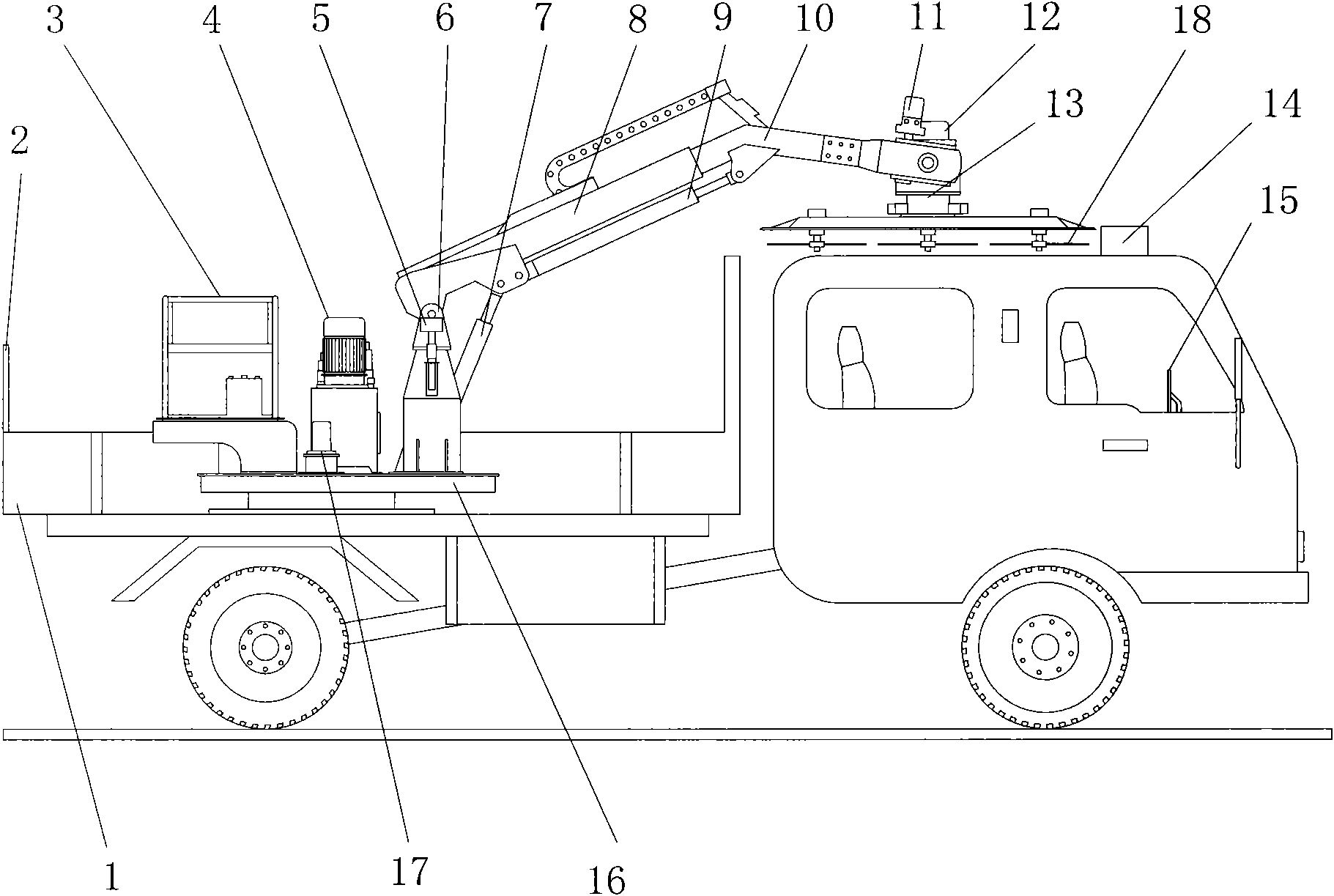

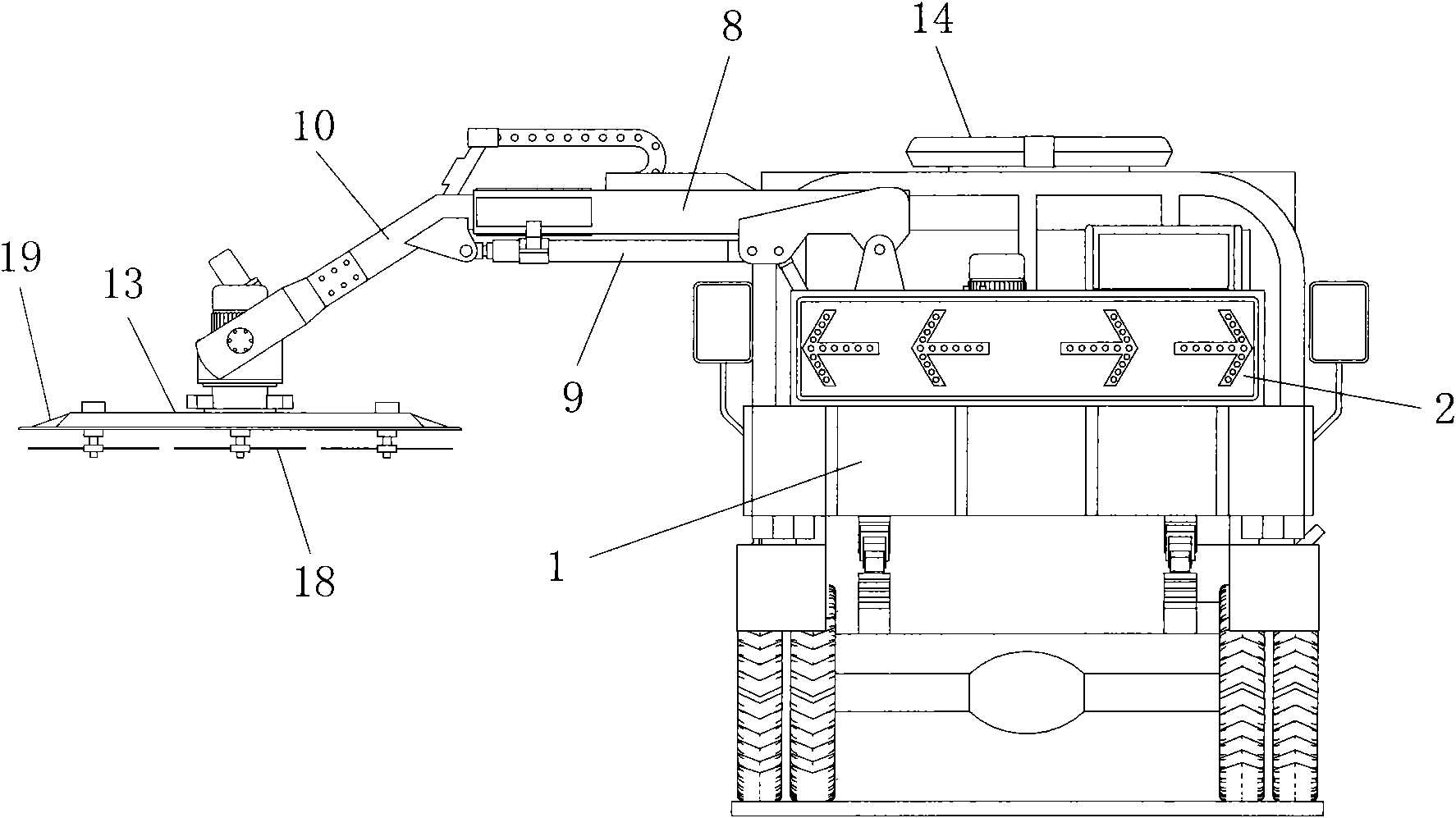

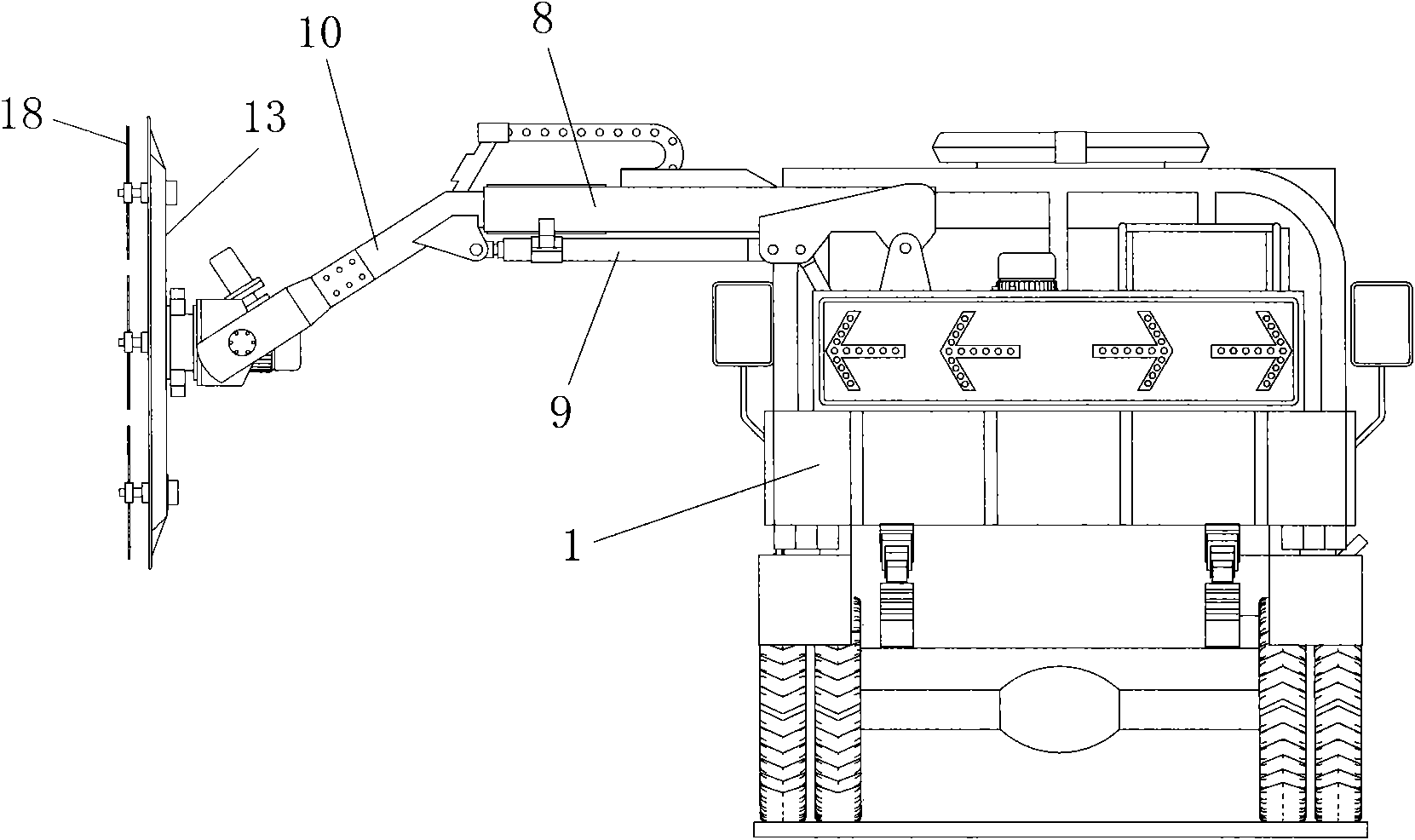

[0039] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, the present invention includes a carrier vehicle 1 and hedge trimming equipment installed on the carrier vehicle 1; the hedge trimming equipment includes a swivel base 16 that is horizontally installed on the carrier vehicle 1 and can rotate 360° on a horizontal plane, and is installed on the carrier vehicle 1. On the rotating base 16, the telescopic arm that can be telescopic and moved up and down at the same time, the cutter head frame 13 fixedly installed on the front end of the telescopic arm, and a plurality of rotating cutter heads 18 horizontally installed below the cutter head frame 13 through the installation shaft 1. The cutter driving mechanism that drives the rotary cutter head 18, the cutterhead turning drive mechanism 11 that connects with the cutterhead frame 13 through the transmission mechanism and drives the cutterhead frame 13 to perform four-round flipping act...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com