Y-Sb-based composite magnetic particle optical catalyst in nuclear shell structures and application

A technology of shell structure and structural formula is applied to a core-shell structure yttrium-antimony-based composite magnetic particle photocatalyst and its application field, and can solve the problems of low photocatalytic efficiency, high photocatalytic efficiency, and low utilization rate of sunlight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

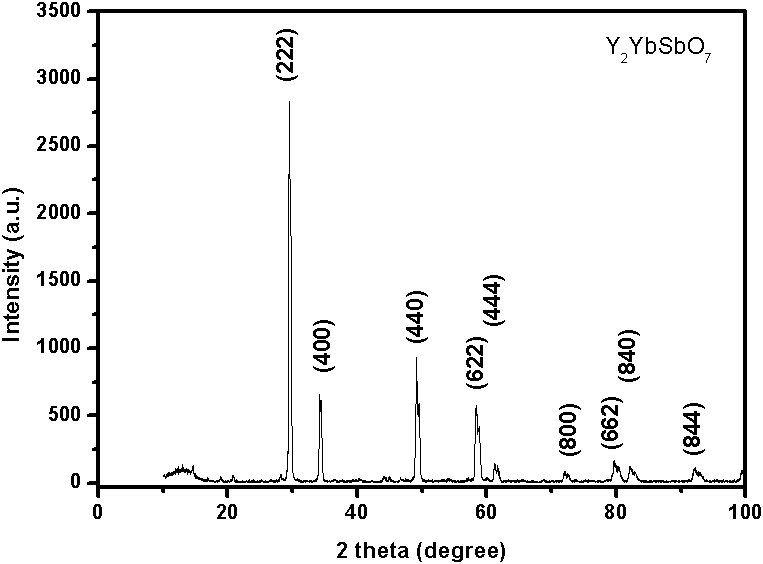

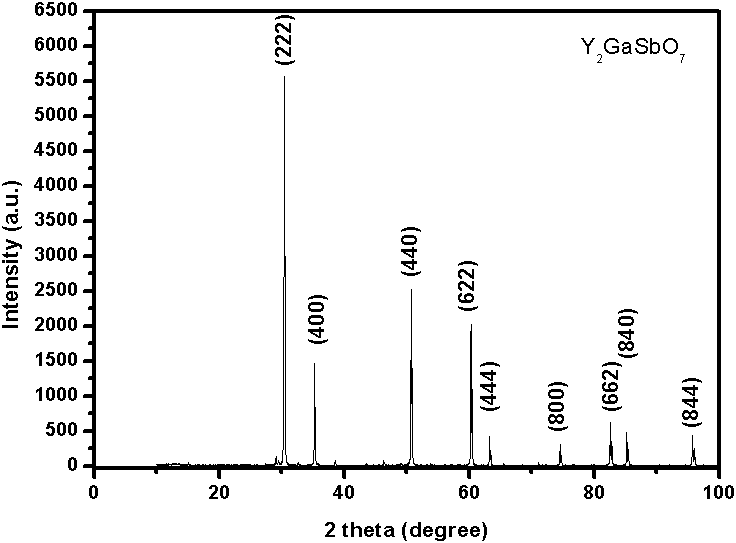

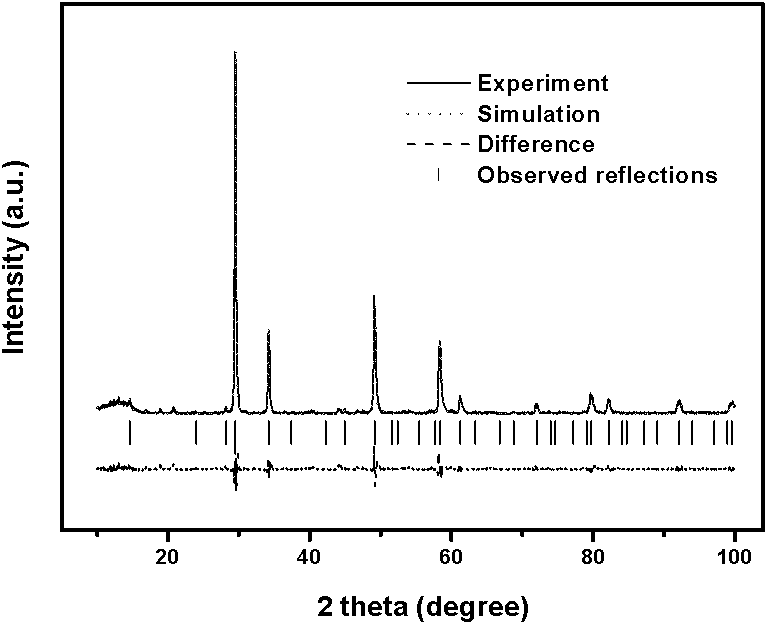

[0043] 1. Powder catalytic material Y 3-x Yb x SbO 7 (0.5≤x≤1) and Y 3-x Ga x SbO 7 (0.5≤x≤1) preparation process route is as follows:

[0044] (1) Powder catalytic material Y 3-x Yb x SbO 7 Preparation of (0.5≤x≤1): Y is prepared by high-temperature solid-state sintering 3-x Yb x SbO 7 (0.5≤x≤1) photocatalytic powder material. Y with a purity of 99.99% 2 o 3 , Yb 2 o 3 and Sb 2 o 5 As a raw material, Y, Yb, Sb are Y in the atomic ratio of the molecular formula 2 o 3 , Yb 2 o 3 and Sb 2 o 5 Mix thoroughly, then grind in a ball mill, the particle size of the powder reaches 1.4-1.8 microns, dry at 200±40°C for 4±1 hours, press into tablets, and put them into a high-temperature sintering furnace for firing. Raise the temperature of the furnace to 700±20°C, keep it warm for 8±2 hours, then cool down with the furnace, take out the pressed powder and crush it to a particle size of 1.3-1.6 microns, then press the powder into a tablet, put it into a high-tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com