Double-saw-blade cutting machine capable of adjusting cutting angle

A technology of cutting angle and double saw blades, which is applied in the direction of sawing machine, metal sawing equipment, metal processing equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

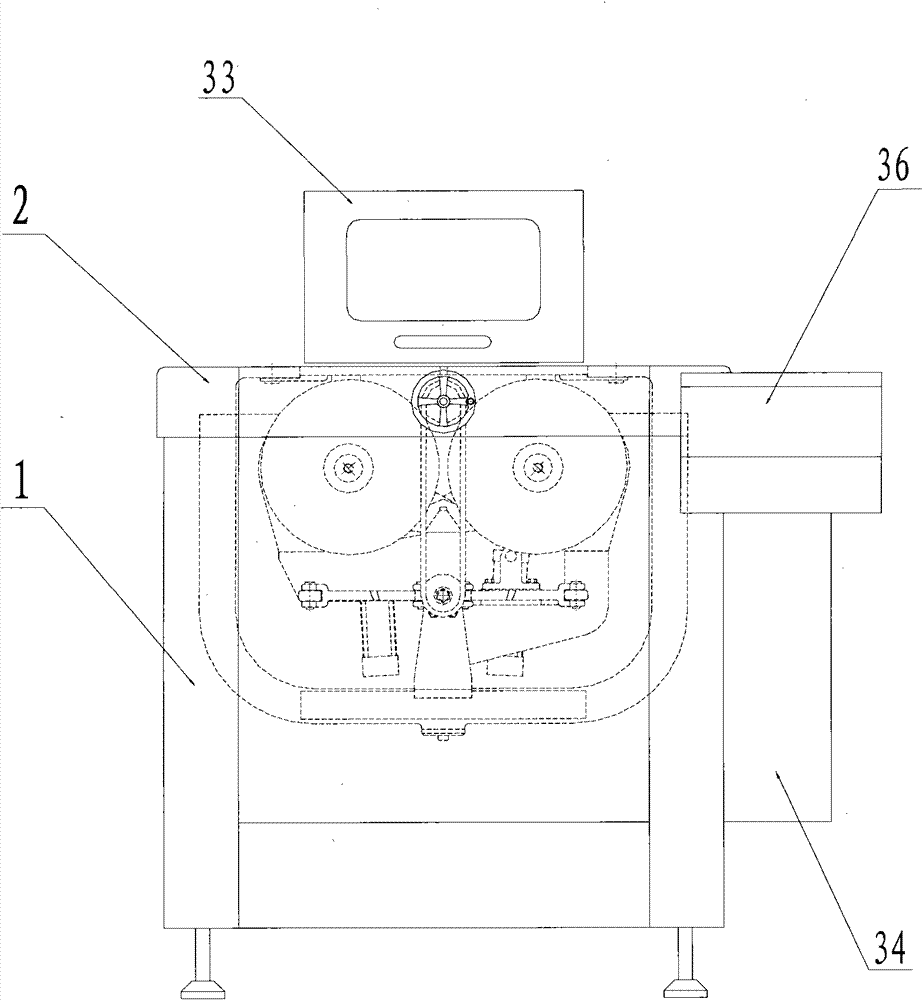

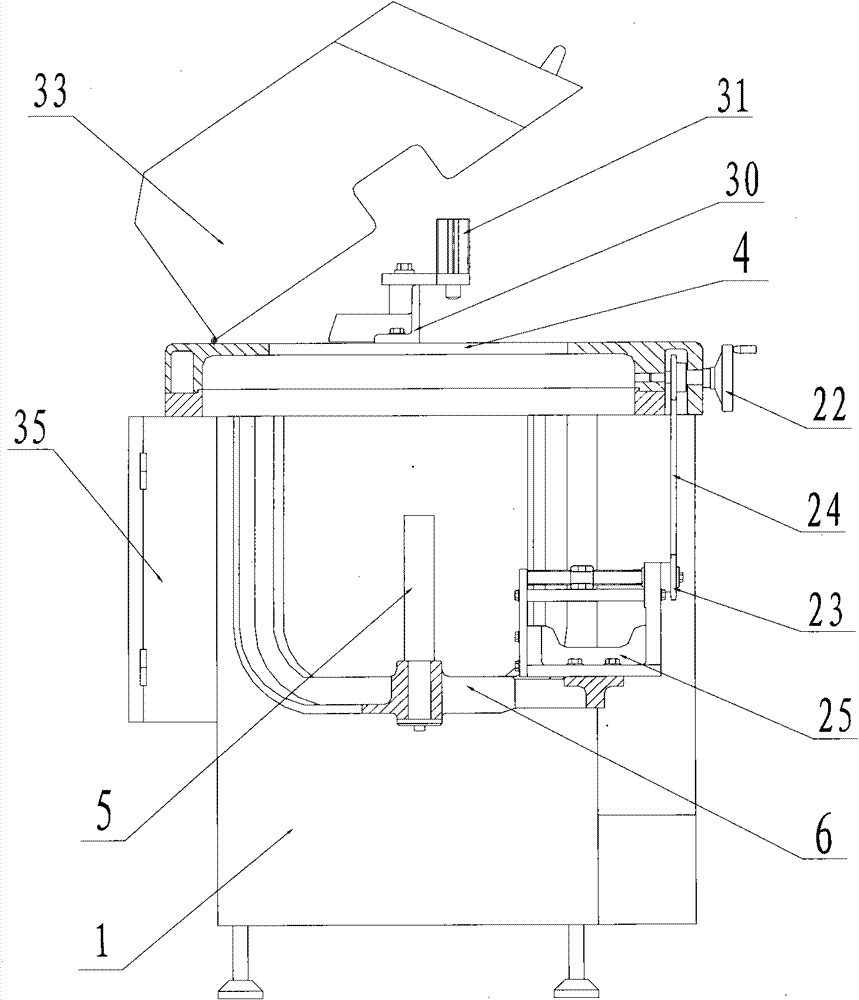

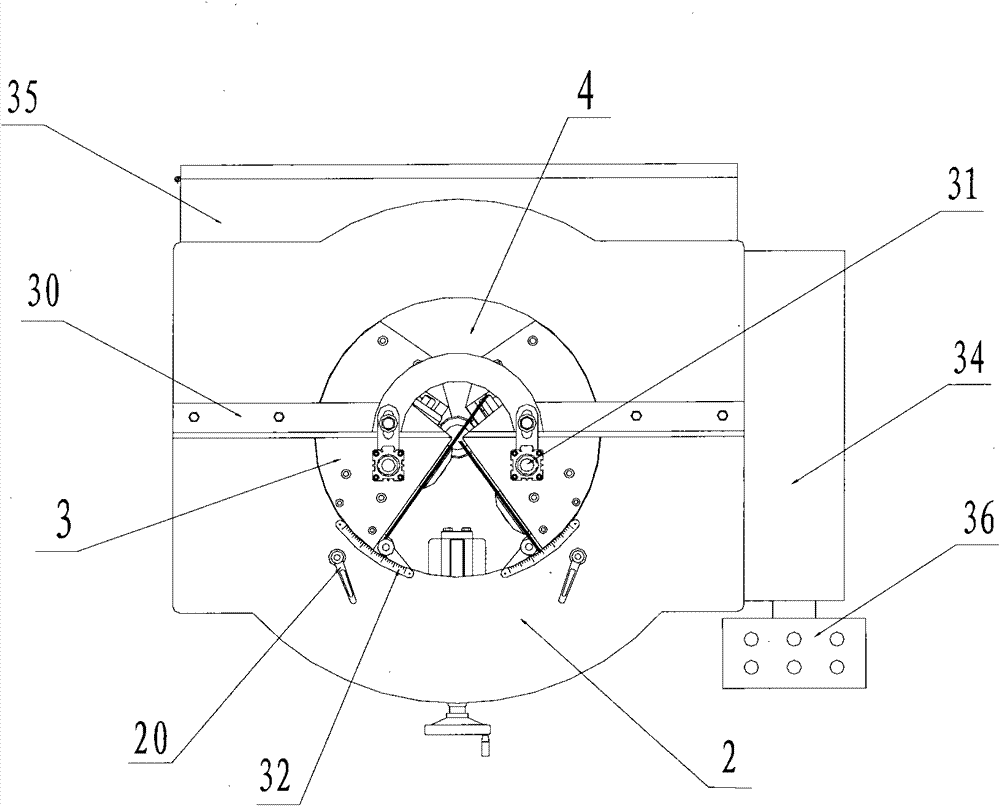

[0023] see Figure 1 to Figure 6 , the adjustable cutting angle double saw blade cutting machine of the present embodiment mainly includes a frame 1, a workbench 2, a rotating workbench 3 (a pair), a central shaft 5, a central shaft support 6, saw blades 7 (two pieces) ), motor 8, (two), swing arm 9 (two), arm shaft 10 (two), arm shaft seat 11 (two), rotating support 12 (one pair), swing arm Power unit 13 (two sets), cylinder connection support 14 (two sets, one set of two)), connecting piece 17 (two sets, one set of two), fixing piece 19 (one pair), synchronous rotating device 25 ( Select when needing synchronous rotation) and composition such as back plate 30.

[0024] The frame 1 supports the workbench 2, and the upper surface of the workbench 2 is provided with a circular hole 4 matched with the two rotating workbench plates 3, and a central shaft 5 is vertically arranged below the same axis of the holes 4, and the center Axle 5 is fixed by central axis support 6, and ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com