Breaking apparatus, breaking method and breaking plate

A technology for cutting devices and substrates, applied in the direction of welding/welding/cutting items, electrical components, circuits, etc., can solve problems such as inability to perform good cutting and chip shapes that do not meet specifications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]

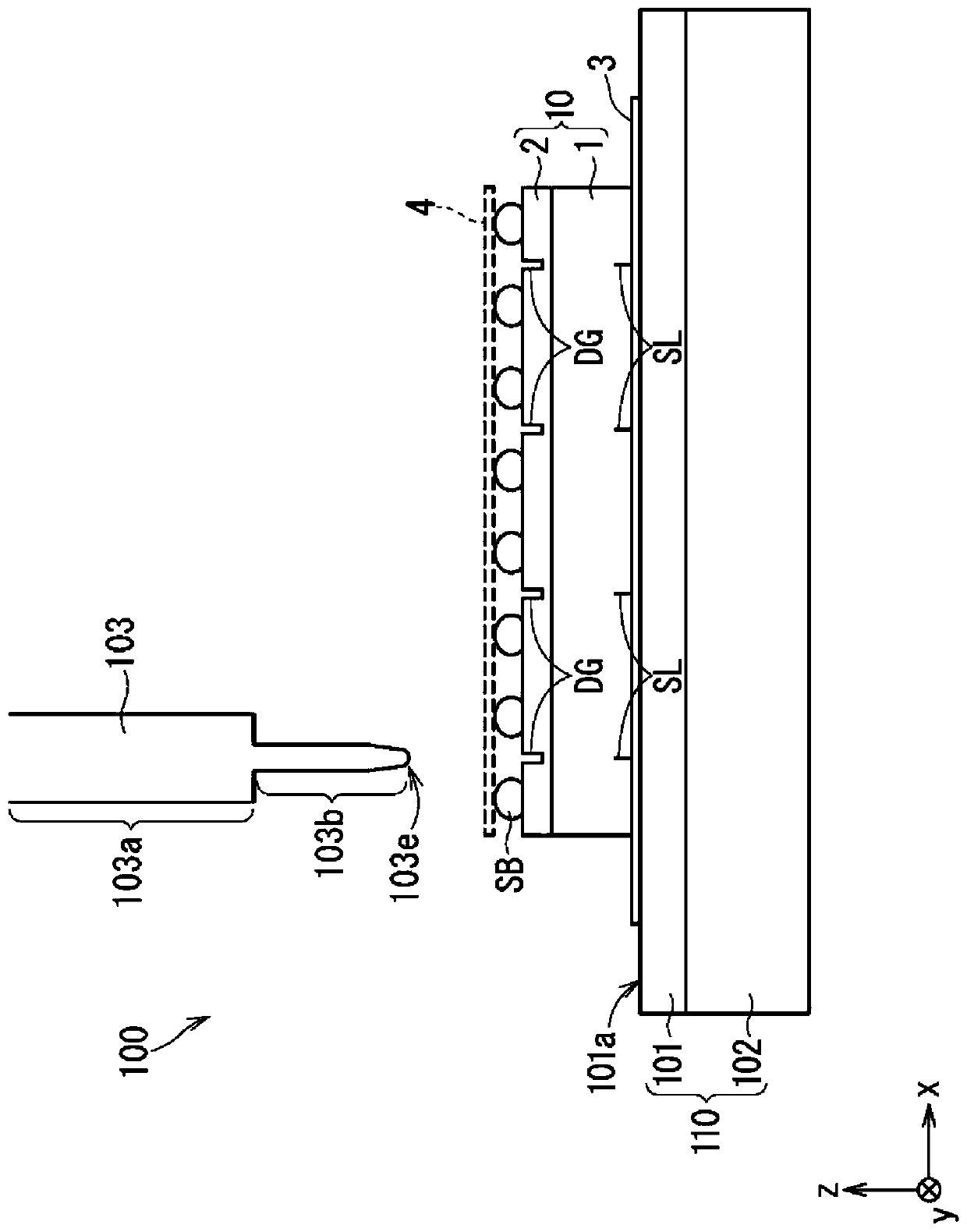

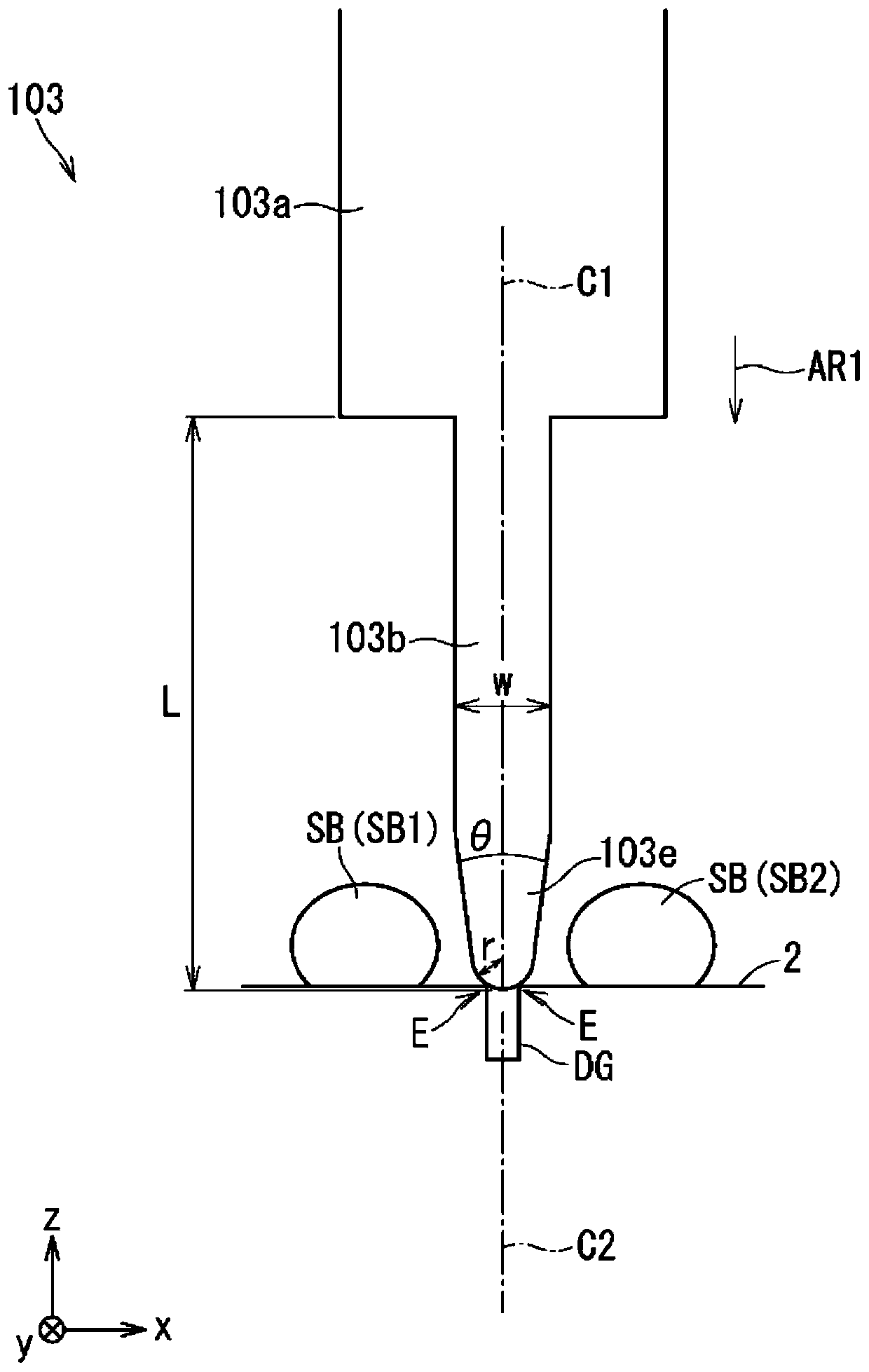

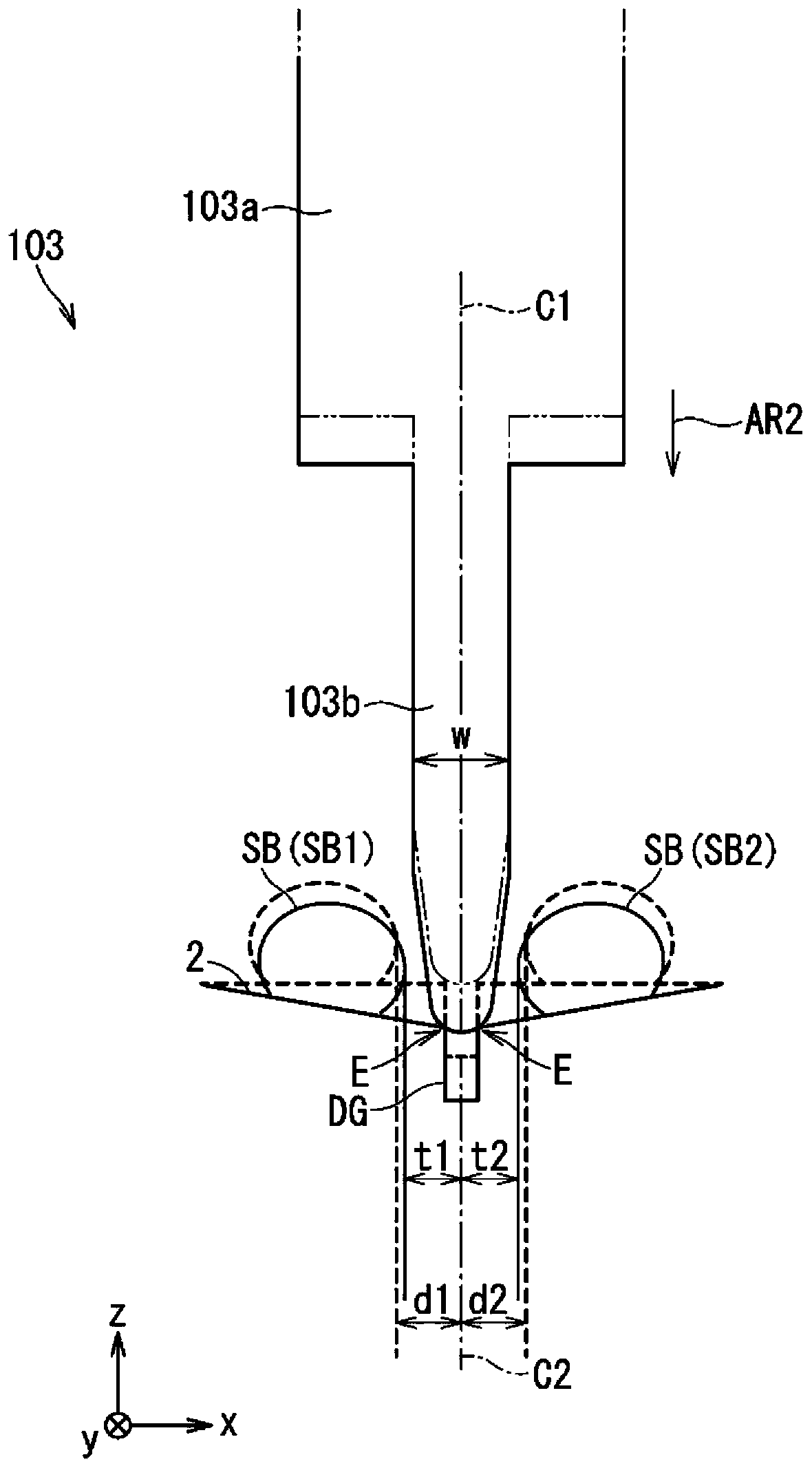

[0021] figure 1 It is a figure which schematically shows the state of cutting the bonded board|substrate 10 using the cutting apparatus 100 of this embodiment.

[0022] The bonded substrate 10 is, for example, a single substrate as a whole bonded by bonding the first substrate 1 and the second substrate 2 made of a brittle material. As the first substrate 1 , in addition to substrates (glass substrates) made of various glasses such as borosilicate glass, alkali-free glass, and alkali glass such as soda glass, a ceramic substrate is also exemplified. As the second substrate 2 , in addition to the silicon substrate, a thermosetting resin substrate is exemplified. In the following description, the first substrate 1 is a glass substrate and the second substrate 2 is a silicon substrate. The first substrate 1 is only described as the glass substrate 1 and the second substrate 2 is only described as the silicon substrate 2 .

[0023] Furthermore, in this embodiment, if ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com