Fully automatic disk striking type unloading machine for quick-frozen food

A quick-frozen food, fully automatic technology, applied in the field of workshop conveying system, can solve the problems of poor working environment, waste of energy, and high labor intensity for workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

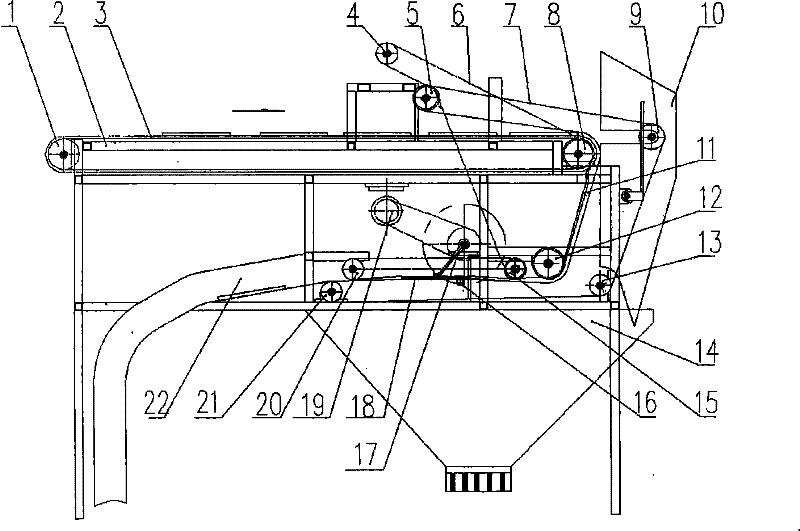

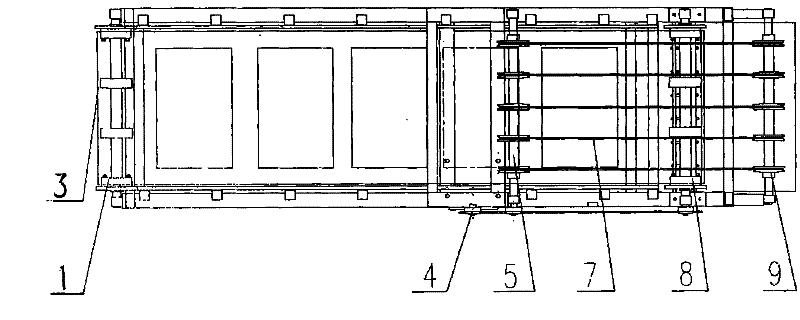

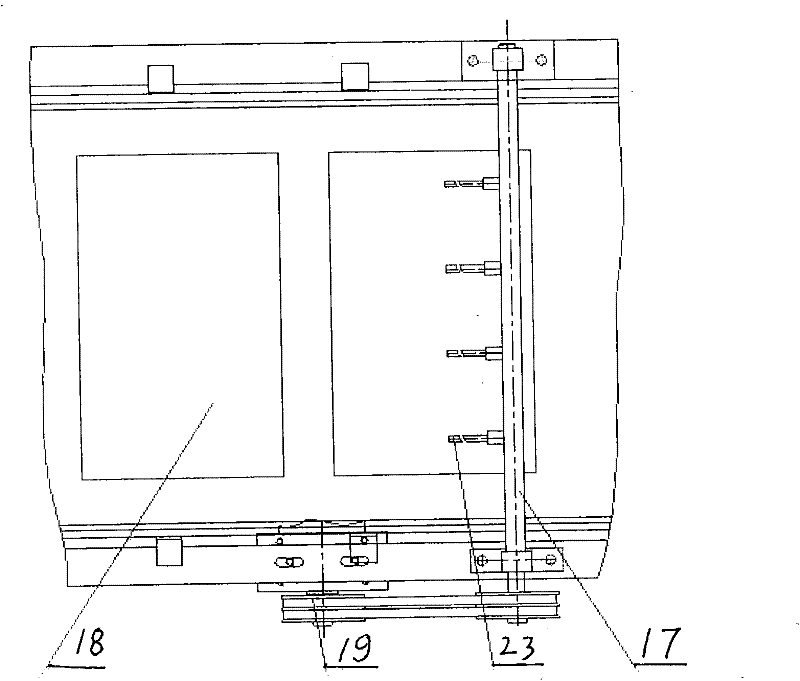

[0007] Further describe embodiment in conjunction with above accompanying drawing, the present invention is to install two conveyor belt rollers 1 and 8 front and back on a frame 2, a conveyor belt 3 is installed on the front and rear conveyor belt rollers, and guard cover is installed on the rear upper part of the frame 10. A receiving hopper 14 is installed under the middle support of the second half of the frame. The front wheel shaft 21 and the rear wheel shaft 13 are respectively installed on the front and back of the middle support in parallel with the upper opening of the receiving hopper. An upper wheel shaft 5 is installed on the frame, and a tensioner wheel shaft 9 is installed parallel to the upper wheel shaft on the frame behind the conveyor belt in the shield. The cylinder shaft 12, a rigid slideway 11 is installed between the conveyor belt rear roller and the cylinder shaft, the outer side passes through the front wheel shaft, the rear wheel shaft, the tension sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com